Intelligent hanging system

An intelligent, hanging technology, applied in the field of hanging systems, can solve the problems of unsuitable unified management of different sewing products, and achieve the effects of facilitating enterprise management, ensuring delivery time, and reducing transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

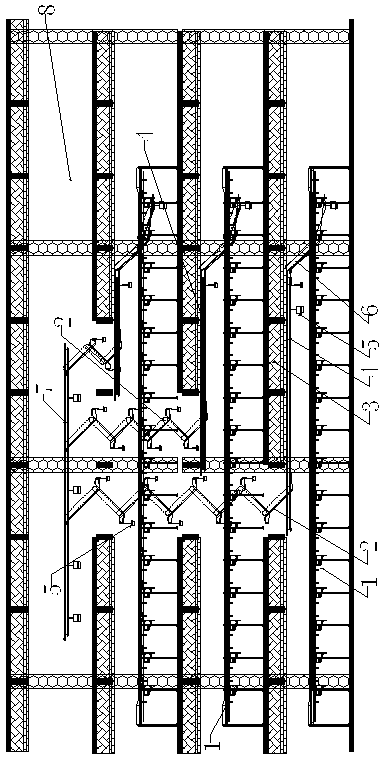

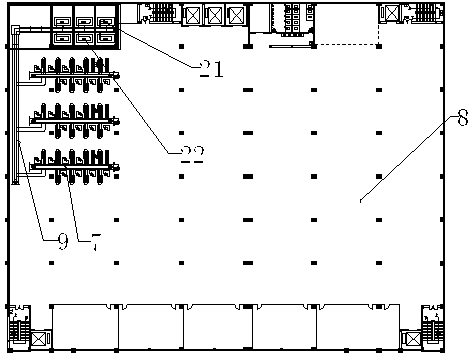

[0021] The intelligent hanging system of the present invention is mainly used in sewing products processing enterprises, so that raw material cloth can be collectively cut according to category, color and specification, and the cut pieces of different sewing products are transported to each corresponding production line 1 On the other hand, when the installation positions of multiple production lines 1 are staggered in the vertical direction, the delivery of cut pieces can also be realized.

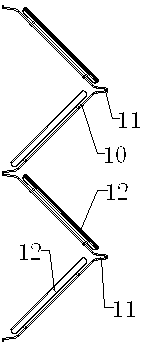

[0022] As shown in the figure, the structure of the intelligent hanging system of the present invention includes a plurality of production lines 1, and at least some of the installation positions of these production lines 1 are staggered from each other in the vertical direction. There is a floor 3 separating them, that is, these production lines 1 are respectively arranged in different floors in the factory building.

[0023] The structure of the production line 1 includes a ring rail and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com