Equipment for producing natural gas by coal

A coal-to-natural gas and equipment technology, applied in the field of new energy, can solve the problems of many cost and safety factors and high cost, and achieve the effect of ensuring cost and safety and continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

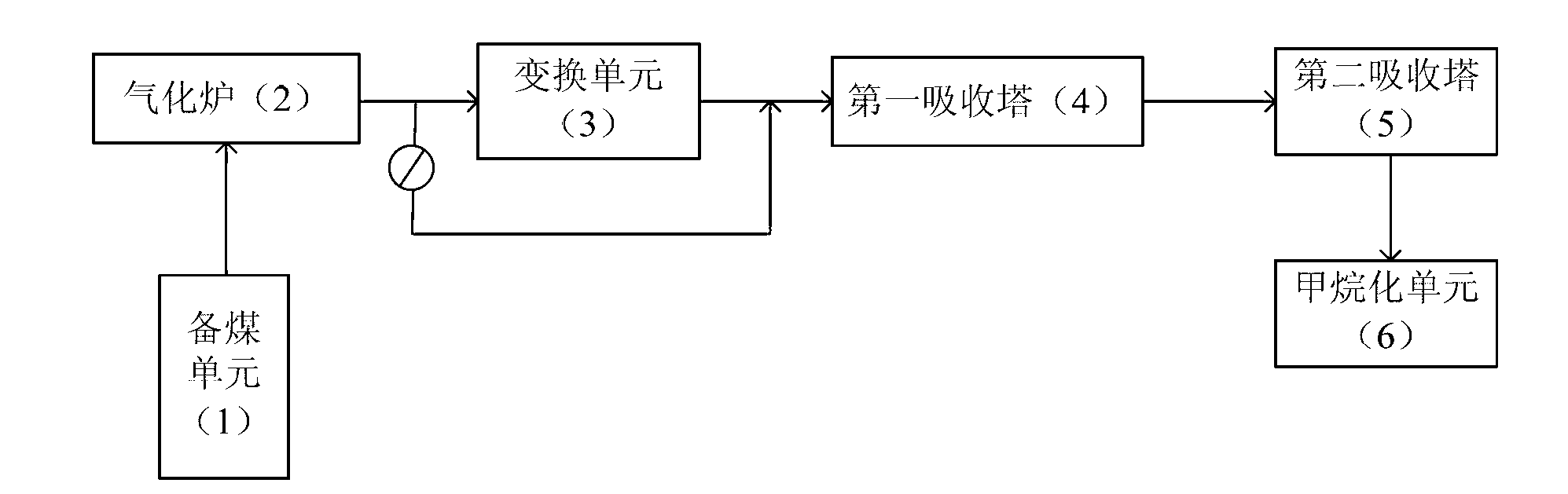

[0014] According to the hydrogen production equipment disclosed in the present invention, the process of coal-to-natural gas is specifically:

[0015] The raw coal is processed by the coal preparation unit (1) and then enters the gasification furnace (2). Steam and air-separated oxygen are injected from the lower part of the gasification furnace (2) as gasification agents. The coal is injected into the gasification furnace (2). In countercurrent contact with the gasification agent, the raw coal is dried, retorted, gasified and oxidized to generate crude coal gas. Crude gas includes: hydrogen, carbon monoxide, carbon dioxide, methane, oxygen, nitrogen, hydrogen sulfide, oil and higher hydrocarbons. The purity of the oxygen is 99.5 vol% to 99.8 vol%, and the pressure of the steam is preferably 1.0 MPa to 10.0 MPa, more preferably 4.8 MPa. In the process of producing hydrogen, the volume ratio of the steam to the oxygen is preferably (5.5-5.8):1.

[0016] The auxiliary line is close...

Example Embodiment

[0022] Example 1

[0023] After the raw coal of the pitkou coal mine is processed by the coal preparation unit (1), it is sent to the gasification furnace (2) through the coal lock; steam and oxygen after air separation treatment are injected from the lower part of the gasification furnace (2) as gasification agents, The volume ratio of steam to oxygen is 5.5:1; the raw coal and the gasification agent are in countercurrent contact in the gasifier (2). After the raw coal is dried, retorted, gasified and oxidized, raw coal gas is obtained. The raw gas contains 0.22vol% O 2 , 0.19vol% N 2 , 9.76vol% CH 4 , 12.32vol% CO, 34.99vol% CO 2 , 41.65vol% H 2 , 0.15vol% H 2 S and 0.72vol% C n H m ; Close the auxiliary line and enter the crude gas into the conversion unit (3) to convert all the carbon monoxide in it into hydrogen, and the obtained crude gas enters the first absorption tower (4) to absorb the impurity gas in the crude gas with methanol as the absorbent, and The temperature ...

Example Embodiment

[0025] Example 2

[0026] After being processed by the coal preparation unit (1), the raw coal of the Kengkou coal mine is sent to a gasifier (2) through the coal lock, and the other three gasifiers are shut down; steam and air-separated oxygen are used as gasification agents from the gas Into the lower part of the chemical furnace (2), the volume ratio of steam to oxygen is 5.8:1; the raw coal and the gasification agent are in countercurrent contact in the gasification furnace, and the raw coal is dried, retorted, gasified and oxidized to obtain crude gas. The gas contains 0.35vol% O 2 , 0.40vol% of N 2 , 10.0vol% CH 4 , 17.0vol% CO, 32.0vol% CO 2 , 38.7vol% H 2 , 0.10vol% H 2 S and 1.45vol% C n H m ; Close the auxiliary line, enter the crude gas into the conversion unit (3) to convert all the carbon monoxide in it into hydrogen, and enter the obtained crude gas into the first absorption tower (4) to absorb the impurity gas in the crude gas with methanol as the absorbent. And...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap