Top conical whole textile reinforcing body composed of multilayer woven fabric

A fabric-reinforced, conical technology, used in fabrics, textiles, textiles and papermaking, etc., can solve the problems of poor profile size accuracy, difficult quality assurance, poor uniformity and consistency of fiber volume content, etc. The effect of increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

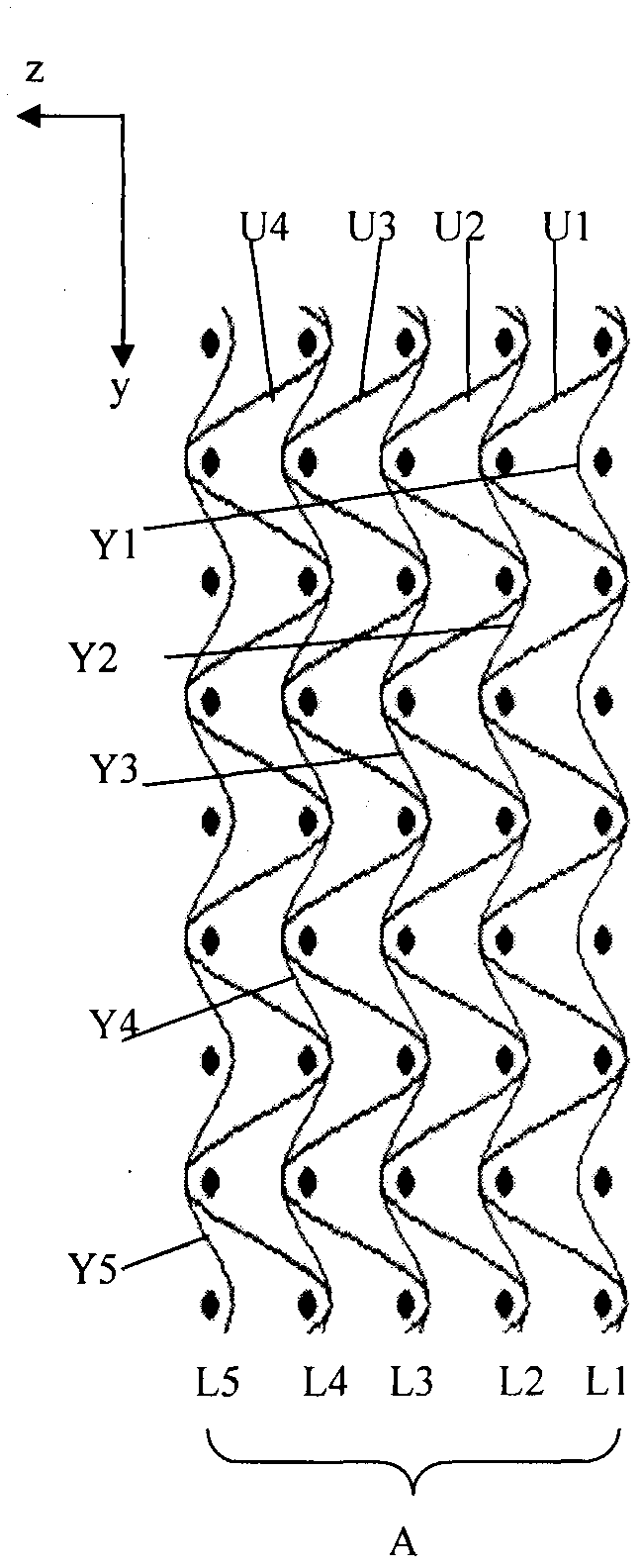

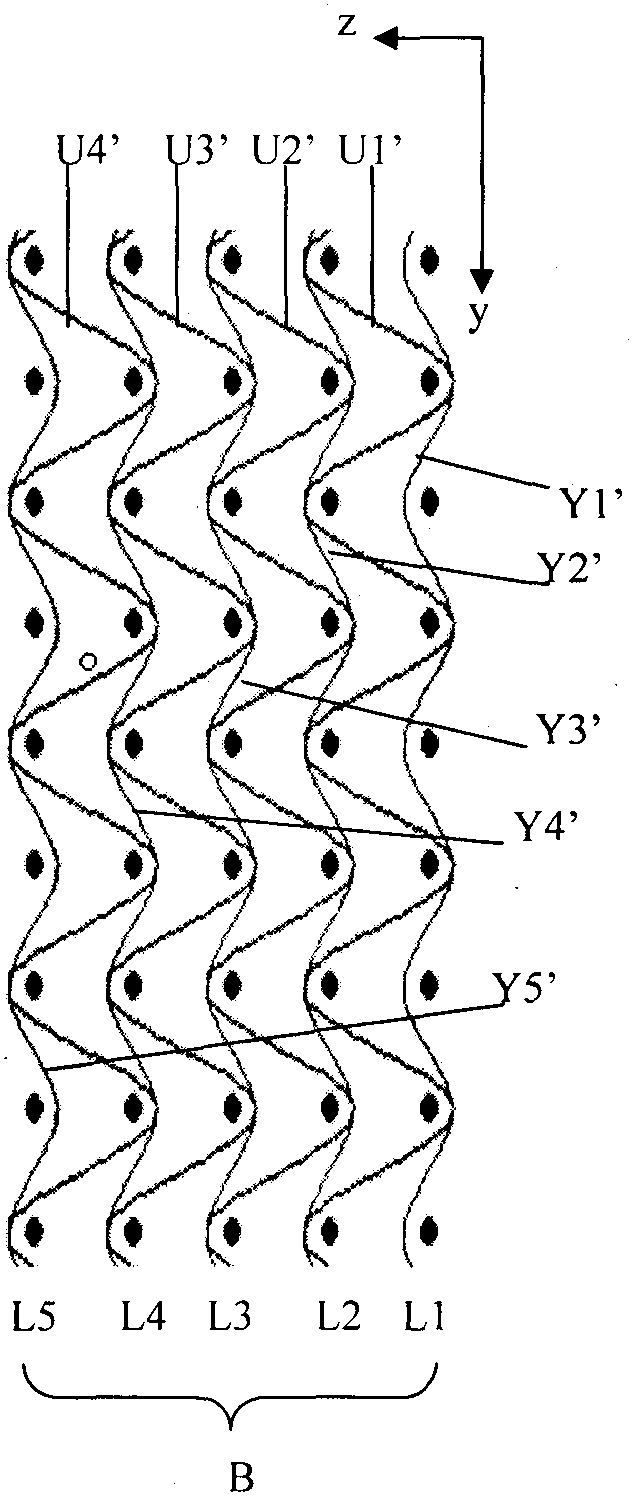

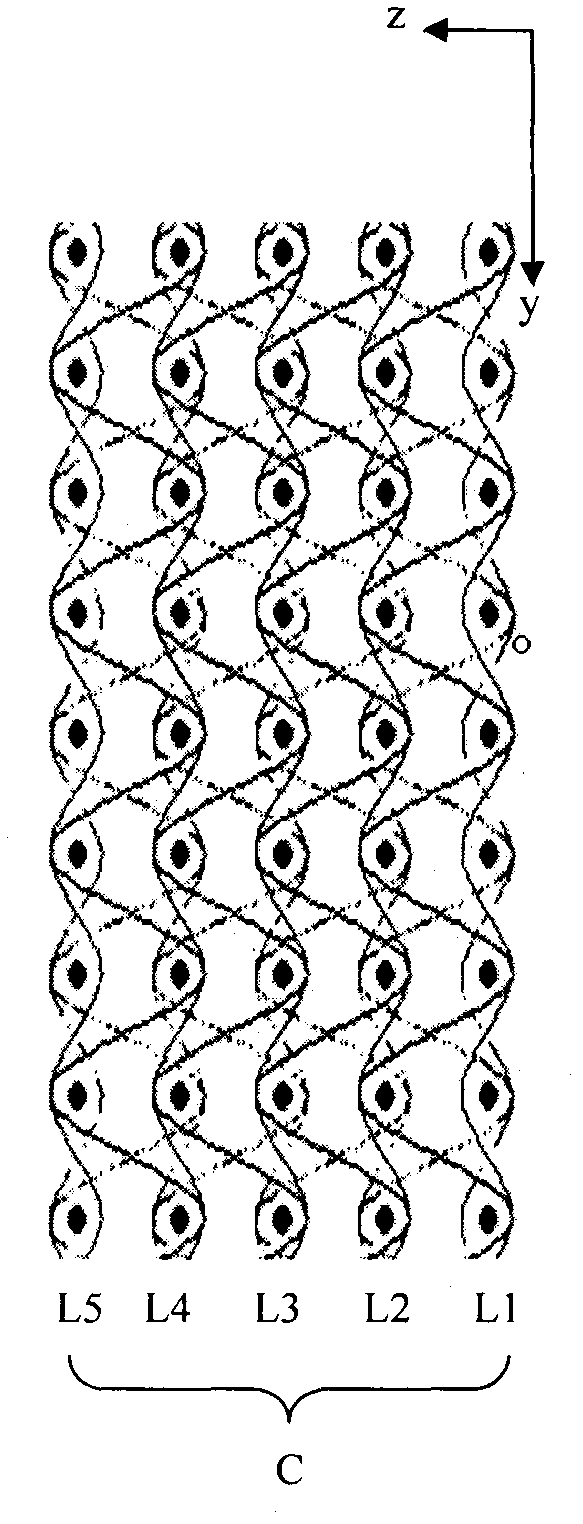

[0019] This embodiment is a conical integral fabric reinforcement with a square top, which is integrally and coherently formed by two parts, the top and the body.

[0020] The top structure of this embodiment is a 5-layer fabric with an overall structure composed of 5 sub-layer fabrics L1, L2, L3, L4, and L5 in thickness, which is to connect 2 layers and above sub-layers by connecting warp yarns in the thickness direction of the fabric. The multi-layer woven fabric is formed by connecting the fabric as a whole, so that the connecting warp yarn is only between two adjacent sub-layer fabrics, and is superimposed with the warp yarn of the sub-layer fabric in the same longitudinal direction in the width direction of the fabric. The way in the cross-section is to realize the connection of the adjacent sub-layer fabrics.

[0021] The top structure can be detailed with figure 1 , 2 , 3 to illustrate the narrative. In the figure, y and z are the length and thickness directions of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com