Snow clearing bucket side plates of snowplow and snowplow

A technology for snow blowers and snow buckets, used in snow surface cleaning, cleaning methods, construction, etc., can solve problems such as large resistance and easy blockage of snow, and achieve the effects of improving efficiency, reducing propulsion resistance, and preventing side plate deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

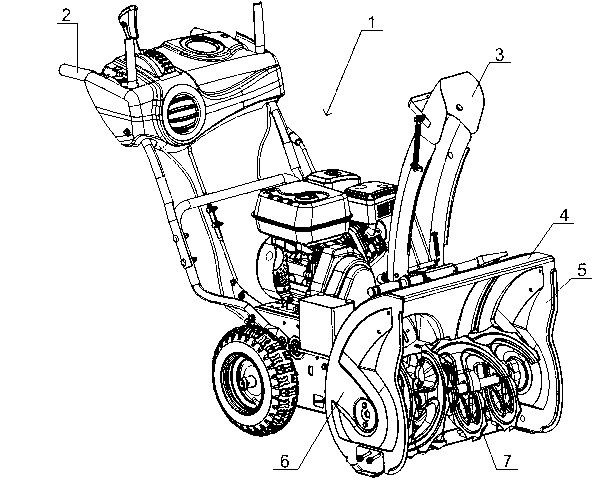

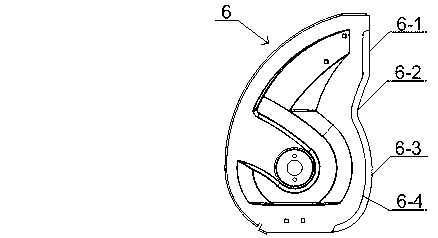

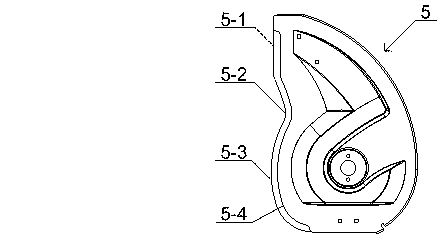

[0028] see figure 1 , the snow blower 1 includes a handle 2, a snow lift mouth 3 and a snow bucket 4, the two sides of the snow bucket 4 are the left snow bucket side plate 5, the right snow bucket side plate 6, and the snow bucket 4 is provided with a stirring cage7.

[0029] see figure 1 , figure 2 and image 3 , in order to make the side plates of the snow clearing bucket gradually cut into the snow layer when clearing snow, so as to reduce the propulsion resistance, the design concept of the present invention is to form a forward edge on the front edges of the left and right snow bucket side plates 5,6. Protruding arc segments 5-3, 6-3, the section of the protruding arc segments 5-3, 6-3 is from the middle upper part to the lower part. Since the protruding arc sections 5-3 and 6-3 do not contact the snow layer at the same time, but gradually cut into the snow layer, the resistance is reduced and the snow-clearing effect is improved.

[0030] As far as the speci...

Embodiment 2

[0035] Different from Embodiment 1, there is no concave section, and the front edges of the left and right snow bucket side plates 5, 6 form a straight line section and a protruding arc section sequentially from top to bottom. The protruding arc occupies about 60% of the area, that is, extending from the upper middle part of the side panel to the lower part.

Embodiment 3

[0037] Change the straight line section of embodiment 1 into a protruding arc segment, and the protruding high point of the protruding arc segment is slightly smaller than the protruding arc segment, namely forming a small protruding arc segment. That is, the front edges of the left and right snow bucket side plates 5, 6 form a small convex arc section, an inner concave section and a convex arc section sequentially from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com