Screw thread twist-stretch transverse stretch-draw prestress exerting system of adjustable and controllable bamboo and wooden beam

A technology of lateral tensioning and thread tensioning is applied in the field of wooden beams and prestressed bamboo, which can solve the problems of complex application process, low accuracy, uncontrollable prestress size and beam deformation, and achieves simple process, Overcome the effect of increased deformation and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

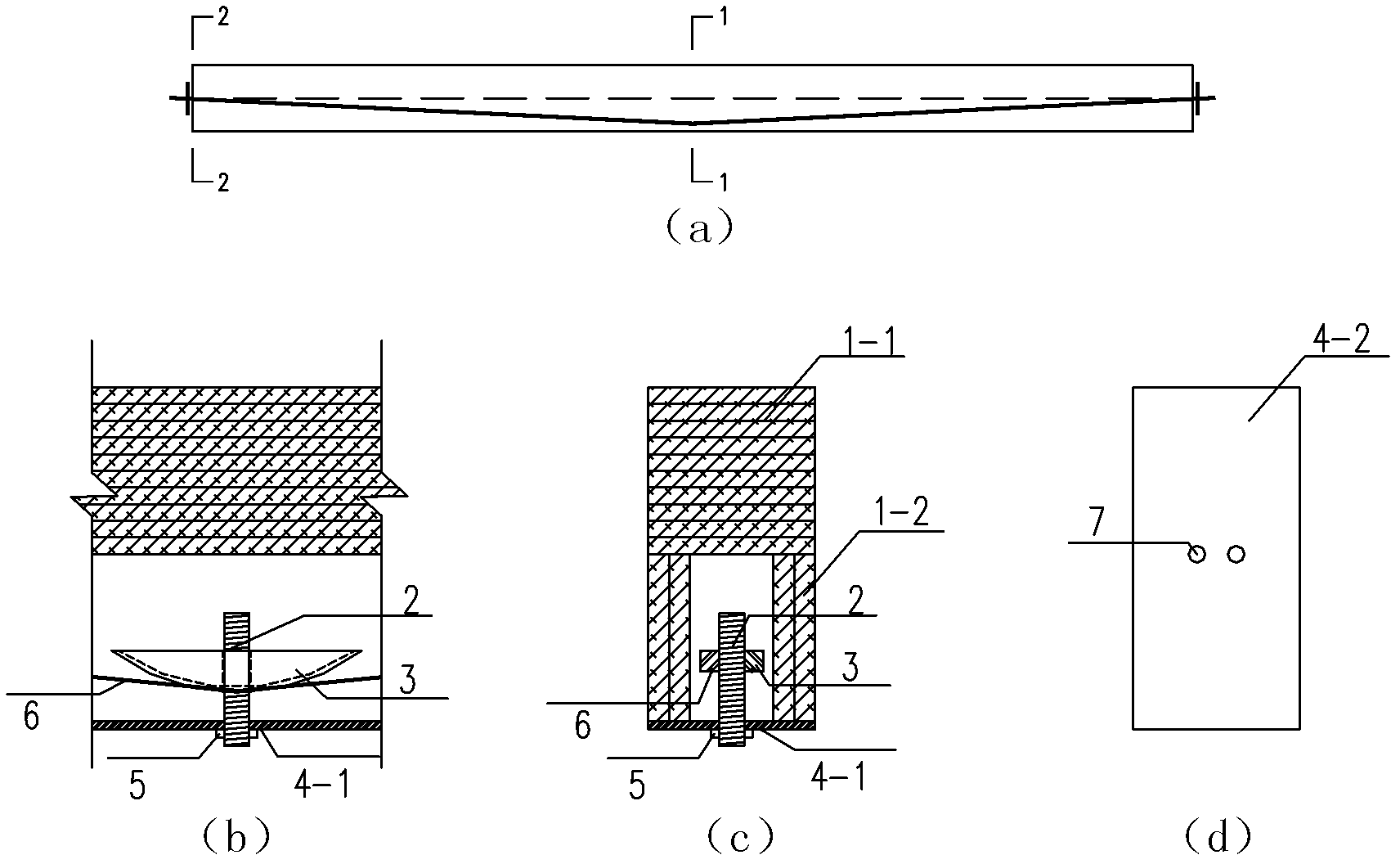

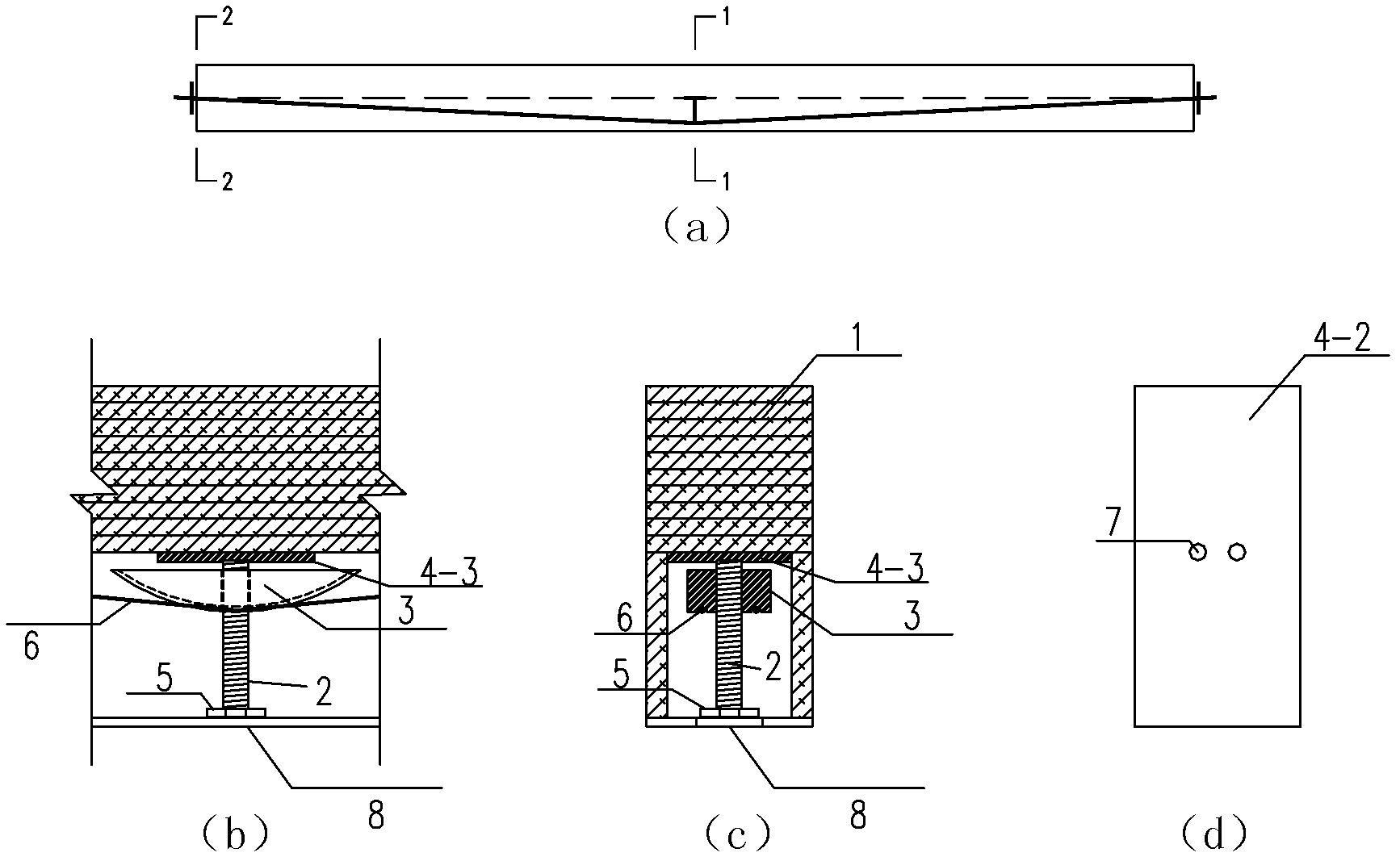

Embodiment 1

[0025] Embodiment 1: the size of the prestressed wooden beam is 3000X200X400, the size of the bamboo and wood material (1-1) in the top compression area is 3000X200X200, and the prestressed tendon (6) selects 6 1860-grade low-relaxation prestressed steel wires with a diameter of 5mm. When the bolt rod (2) within the beam height range is extended by 60mm, the tensile stress of the prestressed tendon (6) increases by 888.77N / mm 2 , The center of the prestressed wooden beam arches 7.65mm. When the deflection is the main control factor, it can save 55.6% of wood, and according to the current market price, it can save 34% of the cost; when the bearing capacity is the main control factor, it can save 33.3% of wood.

Embodiment 2

[0026] Embodiment 2: The size of the prestressed wooden beam is 6000X400X800, the size of the bamboo and wood materials (1-1) in the top compression area is 6000X400X400, and the prestressed tendons (6) use 6 1860-grade low-relaxation prestressed steel wires with a diameter of 7mm. When the bolt rod (2) within the beam height range is extended by 120mm, the tensile stress of the prestressed tendon (6) increases by 957.8N / mm 2 , The center of the prestressed wooden beam arches 8.14mm. When the deflection is the main control factor, it can save 33.3% of wood, and the cost can be saved by 27% according to the current market price; when the bearing capacity is the main control factor, it can save 27.3% of the wood, according to the current market price, the cost can be saved 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com