Anti-icing and deicing system for large wind power generation built-up blade

A combined blade and anti-icing technology, applied in wind turbine components, wind turbines, engines, etc., can solve problems such as high cost and environmental impact of deicing agents, achieve light weight, avoid lowering of power generation efficiency, and high heat utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

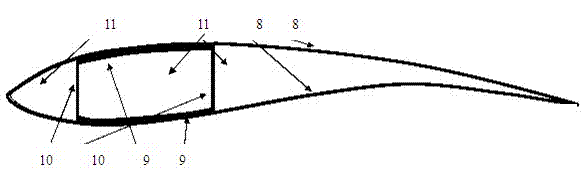

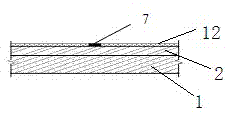

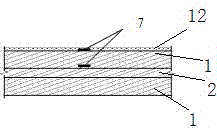

[0035] Such as Figure 1-Figure 9 As shown, an embodiment of the present invention includes a combined blade body, on which a skin 8 made of a blade skin fiber base material layer 1 is provided, and a fiber heating material layer 2 is laid on the skin 8 or the fiber heating material layer 2 is arranged as an interlayer on the middle layer of the fiber base material layer 1; or the fiber heating material layer 2 is arranged on the inner surface of the fiber base material layer 1; the skin 8 A coating 12 is laid on it; two ends of the fiber heating material layer 2 are respectively connected to a conductive electrode 3, and the conductive electrode 3 is connected to a fiber heating power supply 5 through a wire 4; the surface of the skin 8 and the surface of the skin 8 A temperature sensor 6 is provided on the fiber material layer 2 , and the temperature sensor 6 is connected with a temperature controller 7 . The temperature controller 7 is connected to the fiber heating power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com