Multi-phase separation self-cleaning drainage device

A multi-phase separation, self-cleaning technology, applied in the components of pumping devices for elastic fluids, variable displacement pump components, machines/engines, etc. and other problems, to achieve the effect of prolonging the service life, improving the extraction efficiency, and increasing the economic benefits of oil production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

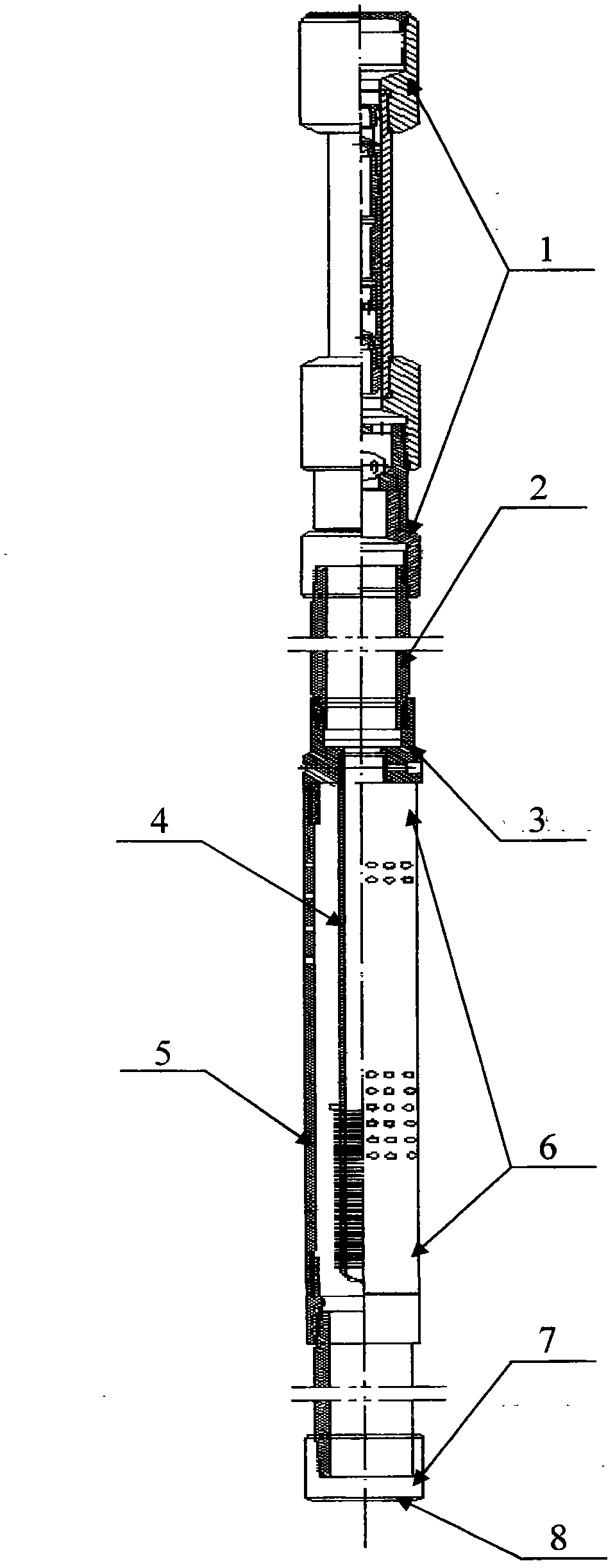

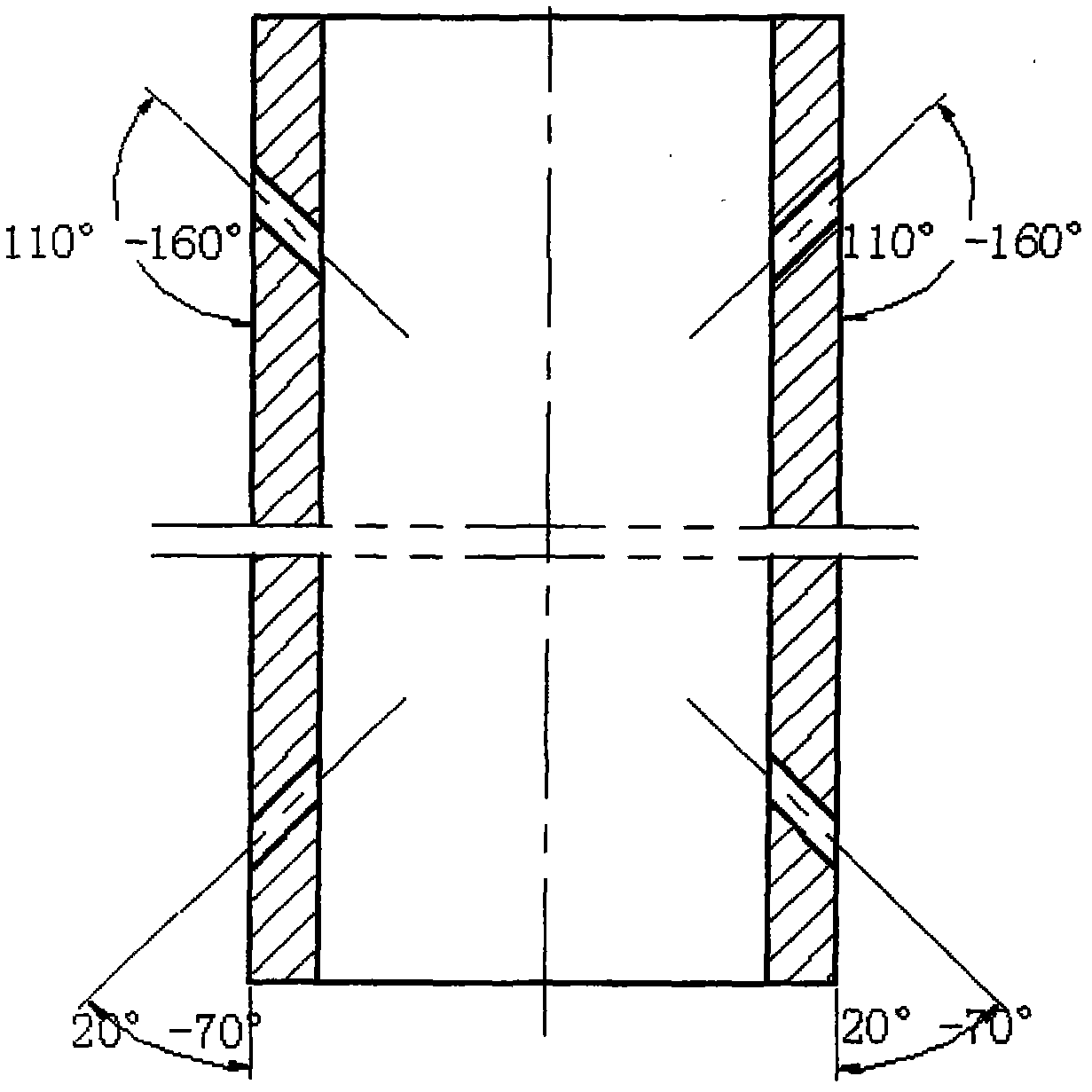

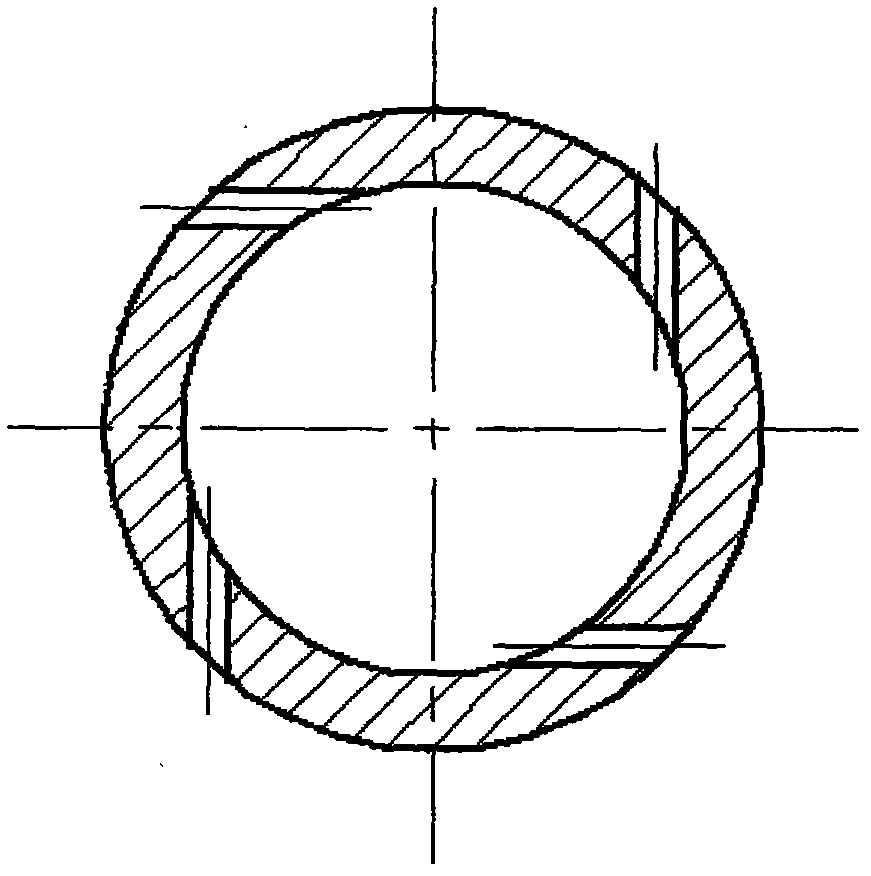

[0012] The device is mainly composed of two parts: the oil well pump assembly and the multi-phase separation self-cleaning drainage device. When going down the well, 10-20 tailpipes equipped with plugs are lowered into the well first, and then connected to the multi-phase separation self-cleaning drainage device sequentially. The extraction device is then connected in series with several oil pipes, and then the oil well pump assembly and the oil pipe are connected in series until reaching the total length of the oil pipe string. The multi-phase separation self-cleaning drainage device is designed and manufactured using the principle of fluid inertia and centrifugal force. It is connected with the oil pump assembly and then lowered into the oil well. The medium enters the device through the through hole of the outer tube of the device to realize gas, sand, The liquid is automatically separated, and the separated gas is discharged into the oil casing annulus through the upper fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com