Liquid medicine automatic proportioning and heating system for wafer cleaning

A technology of automatic proportioning and heating system, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of large size, rough liquid supply system, inconvenient wafer cleaning, etc. Smooth, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

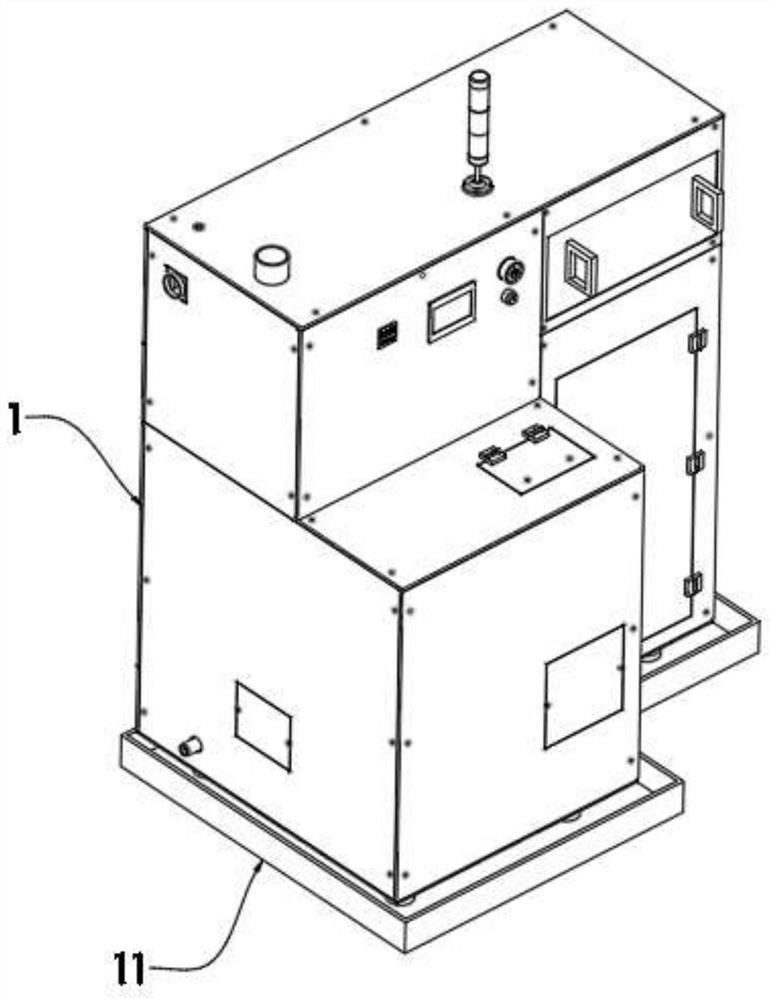

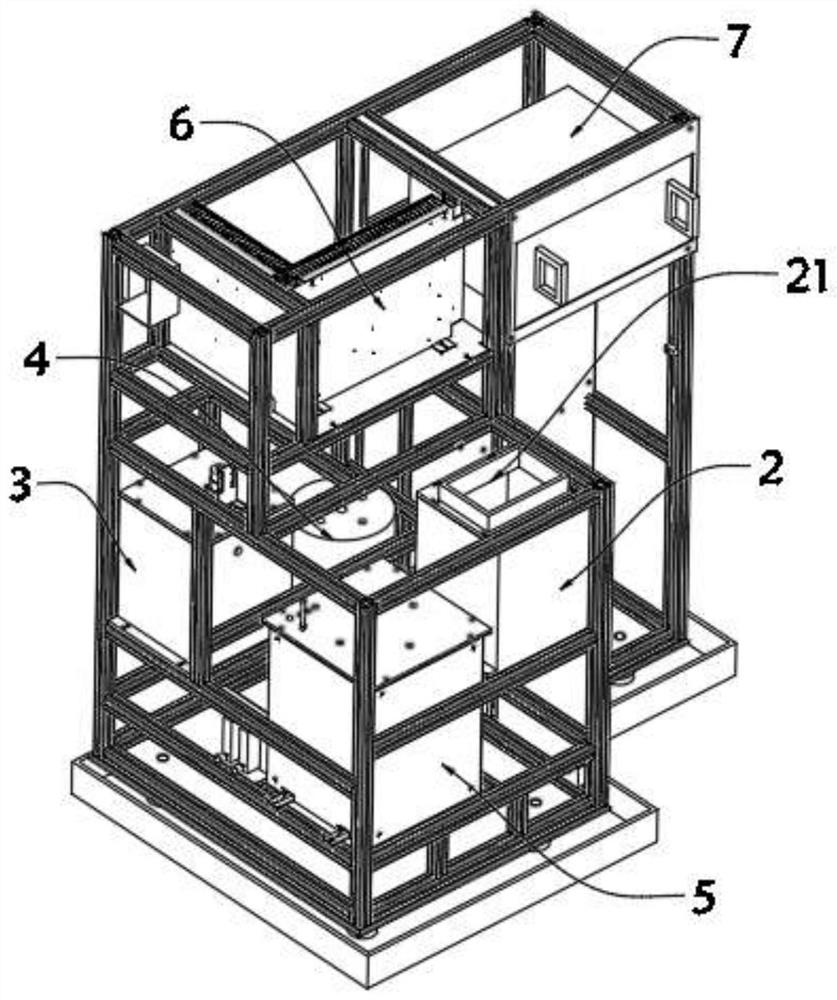

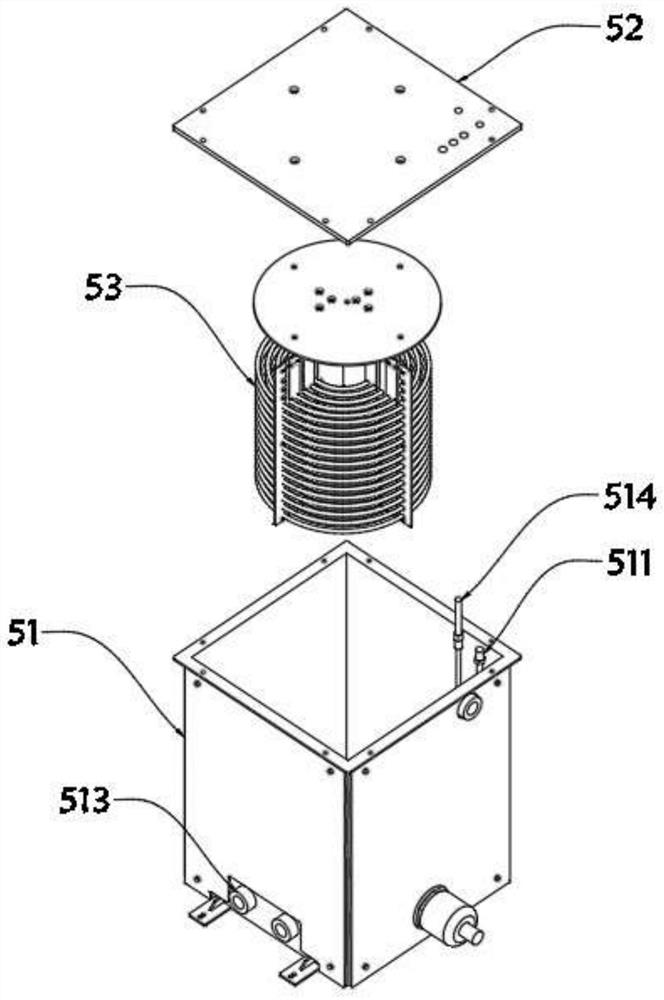

[0023] The present invention provides an automatic proportioning heating system for liquid medicine for wafer cleaning, such as Figure 1-Figure 4 As shown, it includes a shell 1, a raw liquid barrel 2 is installed in the front of the shell 1 for adding medicinal liquid, a proportioning barrel 3 is installed in the rear of the shell 1, and the raw liquid barrel 2 is connected with the proportioning barrel 3 through a pipeline, and the shell 1 A pressure tank 4 is installed in the middle of the inside of the tank, the proportioning barrel 3 is connected to the pressure tank 4 through a pipeline, a first liquid level sensor 41 is installed inside the pressure tank 4, and an intake pipe 42 and an exhaust gas are installed on the top of the pressure tank 4 in turn. The pipeline 43, the intake pipeline 42 and the exhaust pipeline 43 are all equipped with solenoid valves. When the liquid level of the liquid medicine is low, the solenoid valve for controlling the intake pipeline 42 is...

Embodiment 2

[0025] The present invention provides an automatic proportioning heating system for liquid medicine for wafer cleaning, such as Figure 1-Figure 4 As shown, it includes a shell 1, a raw liquid barrel 2 is installed in the front of the shell 1 for adding medicinal liquid, a proportioning barrel 3 is installed in the rear of the shell 1, and the raw liquid barrel 2 is connected with the proportioning barrel 3 through a pipeline, and the shell 1 A pressure tank 4 is installed in the middle of the inside of the tank, the proportioning barrel 3 is connected to the pressure tank 4 through a pipeline, a first liquid level sensor 41 is installed inside the pressure tank 4, and an intake pipe 42 and an exhaust gas are installed on the top of the pressure tank 4 in turn. The pipeline 43, the intake pipeline 42 and the exhaust pipeline 43 are all equipped with solenoid valves. When the liquid level of the liquid medicine is low, the solenoid valve for controlling the intake pipeline 42 is...

Embodiment 3

[0027] The present invention provides an automatic proportioning heating system for liquid medicine for wafer cleaning, such as Figure 1-Figure 4 As shown, it includes a shell 1, a raw liquid barrel 2 is installed in the front of the shell 1 for adding medicinal liquid, a proportioning barrel 3 is installed in the rear of the shell 1, and the raw liquid barrel 2 is connected with the proportioning barrel 3 through a pipeline, and the shell 1 A pressure tank 4 is installed in the middle of the inside of the tank, the proportioning barrel 3 is connected to the pressure tank 4 through a pipeline, a first liquid level sensor 41 is installed inside the pressure tank 4, and an intake pipe 42 and an exhaust gas are installed on the top of the pressure tank 4 in turn. The pipeline 43, the intake pipeline 42 and the exhaust pipeline 43 are all equipped with solenoid valves. When the liquid level of the liquid medicine is low, the solenoid valve for controlling the intake pipeline 42 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com