Integrated double-electronic-control-unit three-position four-way medium-pressure solenoid valve

A three-position four-way, double-electronic control technology, applied in the field of solenoid valves, can solve the problems of complicated air source pipeline and power supply layout, inability to meet the needs of system use, and the existence of pressure source medium, so as to reduce the cost and installation labor intensity. , the effect of improving safety and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

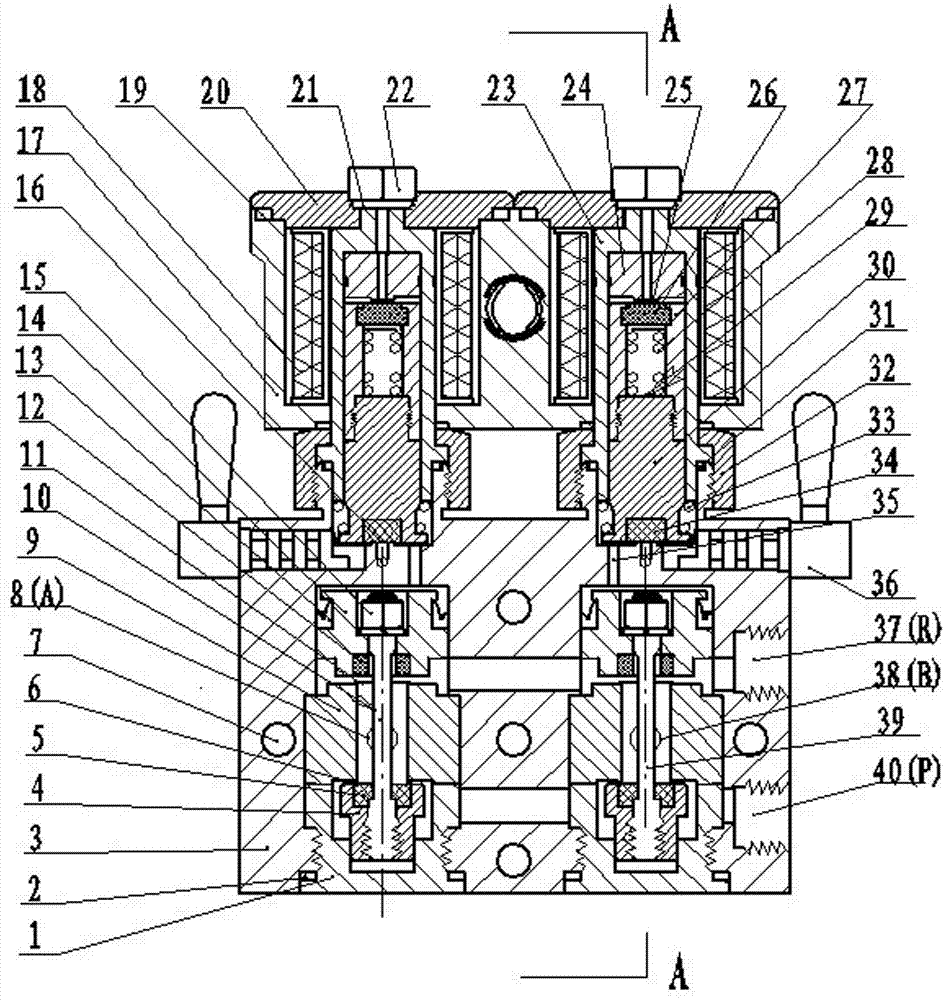

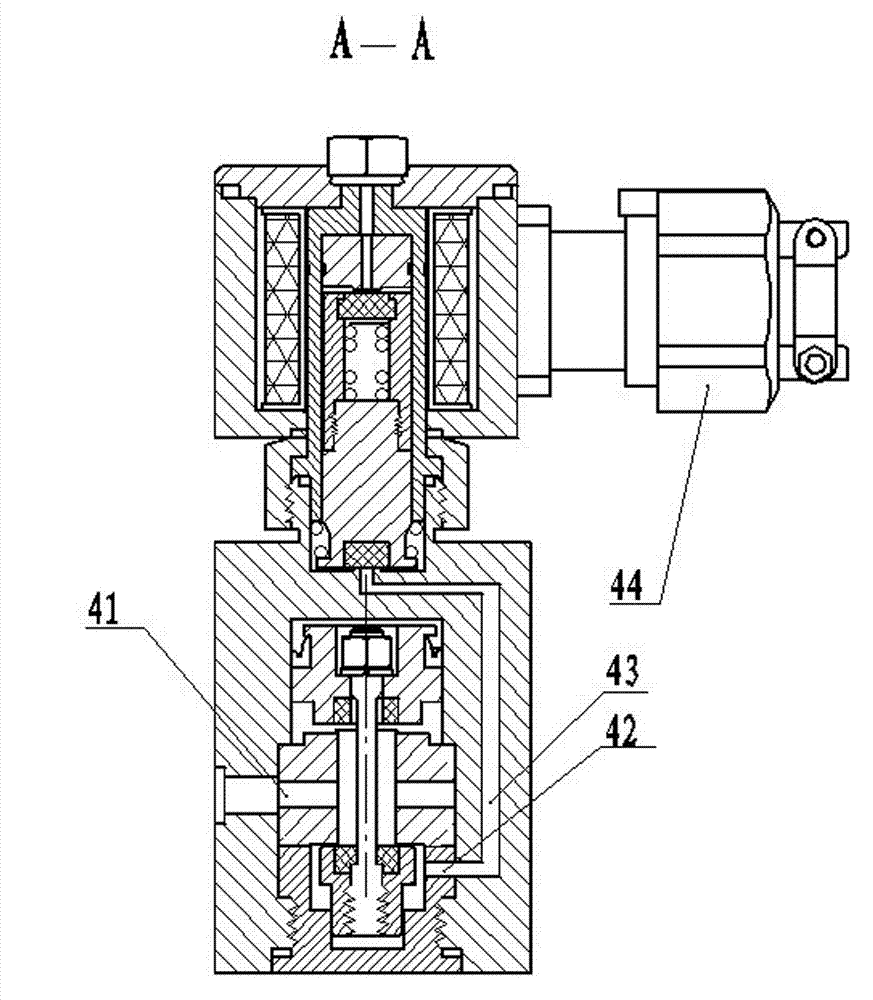

[0020] The integrated dual electric control three-position four-way medium-pressure solenoid valve includes an integrated valve body 3 , a valve core assembly 10 , a coil assembly 18 , an upper cover 20 , a manual device 36 , and a cable connector 44 . The integrated valve body 3 is provided with two valve cavities, a common medium inlet port 40 (P port), a common medium outlet port 37 (R port), two working ports 8 (A port), 38 (B port) , five mounting holes 7, two valve core assemblies 10 of the same structure are respectively placed in the two valve cavities of the integrated valve body, and the pressure plate 1 is threadedly connected with the integrated valve body 3 to compress the valve core assembly so that it cannot be loosened, and the pressure plate 1 and integrated valve body 3 are sealed with gasket 2. Two pilot valve seat ports 16 are respectively provided on the upper end of the integrated valve body 3, and the pilot valve seat ports 16 are connected with the shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com