Electronic type pulse width modulation (PWM) intermittence spray type variable spraying controller

A spraying and electronic technology, applied in the field of variable spraying controllers, can solve the problems of poor uniformity of deposition distribution, complicated operation, high cost, etc., and achieve the effect of simple structure, uniform droplet distribution, and offsetting hydraulic shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further illustrate the utility model below in conjunction with accompanying drawing and embodiment.

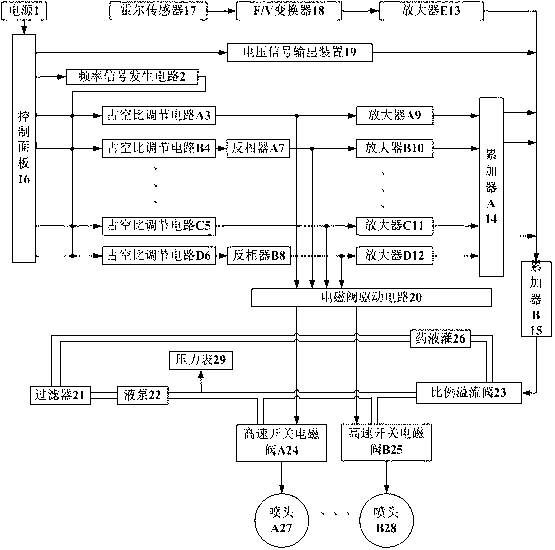

[0019] Such as figure 1 As shown, this electronic PWM intermittent spray variable spray controller consists of an electronic PWM intermittent spray variable spray controller, mainly composed of pipeline subsystems, power supply 1, control panel 4, PWM signal generator, pressure Composition of the stability control subsystem.

[0020] The pipeline subsystem is composed of liquid medicine tank 26, filter 21, liquid pump 22, proportional overflow valve 23, high-speed switch solenoid valve A24, high-speed switch solenoid valve B25, nozzle A27, nozzle B28, filter 21, liquid pump 22, The proportional overflow valve 23 is located on the main pipe of the spray boom. The filter 21 and the proportional overflow valve 23 are connected through the liquid pump 22. The high-speed switching solenoid valve A24 and the high-speed switching solenoid valve B25 are placed in serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com