A Method for Reducing Surface Defects of Aluminum Pad

A liner and defect technology, applied in the field of reducing surface defects of aluminum liner, can solve problems such as peeling, limiting application scope, affecting electrical performance, etc., achieving good step coverage, reducing whisker-like defects, and easily releasing stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

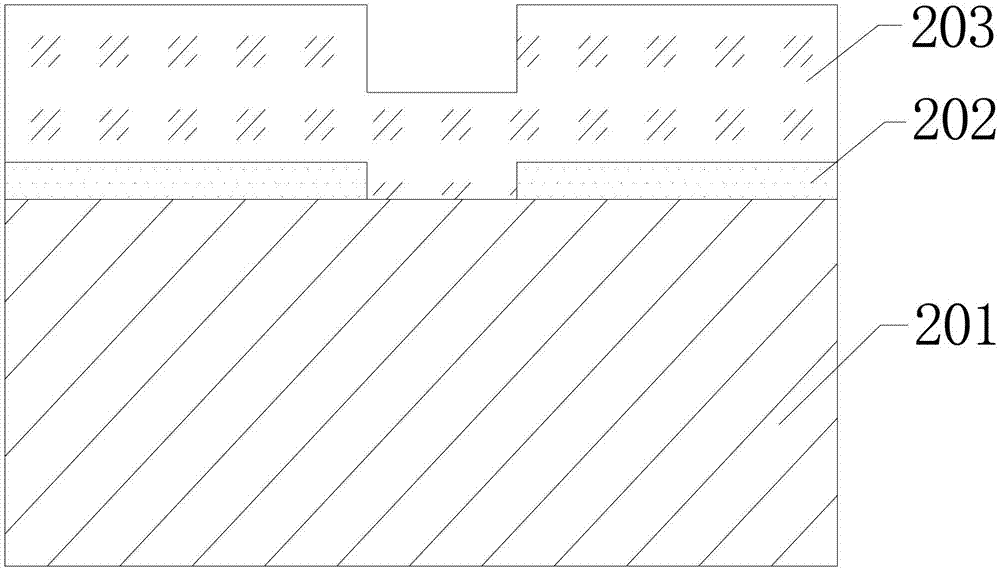

[0038] image 3 is a schematic flow chart of depositing an aluminum liner in the present invention, such as image 3 as shown,

[0039] Step 301: Put the substrate into the first reaction chamber, start the first heating device in the first reaction chamber, and control the temperature T in the first reaction chamber 1 At 100℃≤T 1 ≤220°C, such as 100°C, 150°C, 220°C, etc., and the optimum temperature is 200°C;

[0040] Step 302: Gas is introduced into the first reaction chamber, and the direct current power P applied to the first aluminum target 1 Controlled at 28KW≤P 1 ≤35KW, such as 28KW, 32KW, 35KW, etc., and the optimal DC power is 30KW, the first layer of aluminum deposition process is performed to prepare the first aluminum layer on the upper surface of the substrate;

[0041] Step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap