Rotor punching sheet for permanent magnet motor and rotor

A technology of rotor punching and permanent magnet motor, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., and can solve the problems of low utilization rate of permanent magnet materials, low utilization rate of permanent magnets, and large magnetic flux leakage , to achieve the effect of avoiding low utilization rate, reducing invalid magnetic flux leakage and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

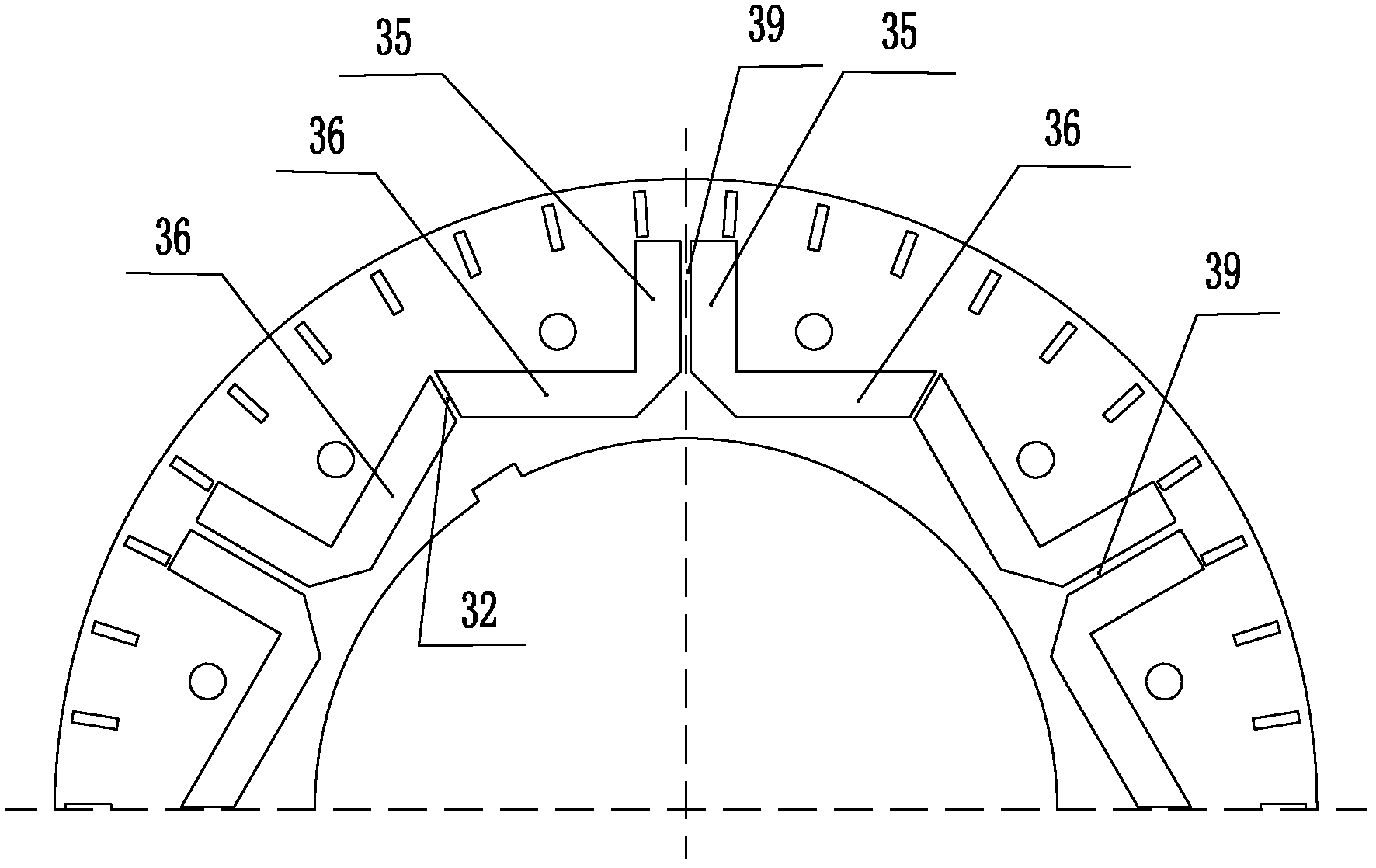

[0013] Such as image 3 As shown, the rotor punching plate used for the permanent magnet motor of the embodiment of the present invention includes a plurality of identical magnetic steel slots, and each magnetic steel slot includes a radial groove 35 arranged along the radial direction of the rotor punching plate and perpendicular to The transverse groove 36 of the radial groove 35, the end of the radial groove 35 is connected with the middle part of the transverse groove 36 and communicated; the radial groove 35 is provided with a connecting part 39 along the radial direction of the rotor punching piece, and the connecting part 39 The through radial groove 35 divides the magnet steel groove into two "L" shaped sub magnet steel grooves, and the radial part of each "L" shaped sub magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com