Purge valve for pressure cooker

A technology for relief valve and cooking utensils, applied in cooking utensils, pressure cookers, household appliances, etc., can solve problems such as hindering the working temperature and working pressure of appliances, aging, material fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

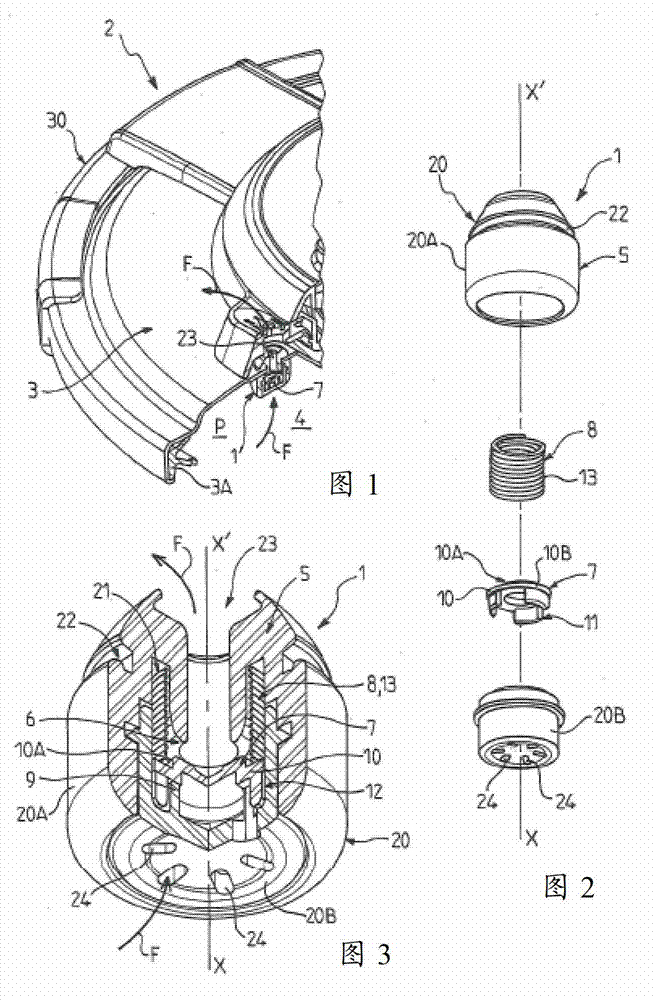

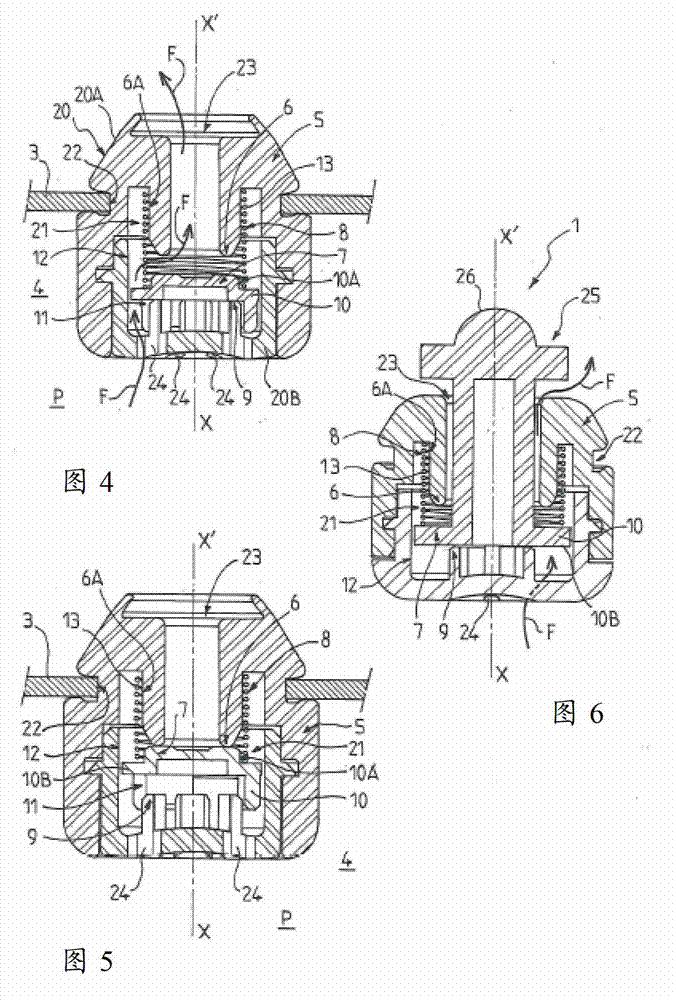

[0024] The present invention relates to a relief valve 1 for a pressure cooking appliance 2 designed to retain its contents in an environment consisting essentially of steam raised to a pressure greater than the ambient atmospheric pressure and in which the The temperature of the steam is raised above ambient atmospheric temperature.

[0025] To this end, said cooking appliance 2 may comprise a container (not shown) and a lid 3 designed to be fixed detachably with said container, thereby defining a substantially airtight and designed to contain the contents of the appliance. The chamber 4.

[0026] Particularly preferably, said appliance 2 constitutes a food cooking appliance of the food pressure cooker type, the content of which may consist of any kind of food.

[0027] However, it is well understood that the appliance 2 can be designed for other uses, for example for sterilization, in particular for the sterilization of containers, jars or instruments, and thus be an autocl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com