Ordinary press machine blocking forging tool set

A technology of blocking forging and press, which is used in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc. problems, to achieve the effect of improving material utilization, reducing forging processes, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0029] It should be noted that the drawings are only for illustrative purposes and should not be construed as limitations on this patent; for those skilled in the art, it is understandable that some known structures and their descriptions in the drawings may be omitted.

[0030] The relevant details and working principles of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

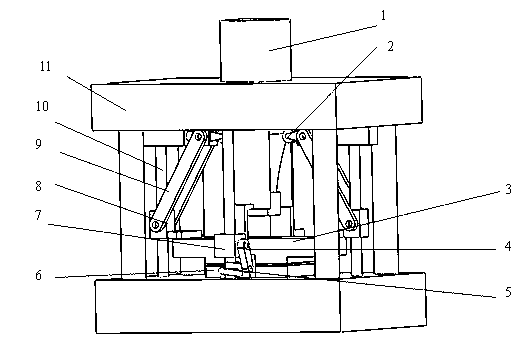

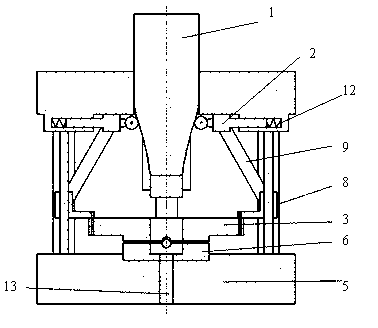

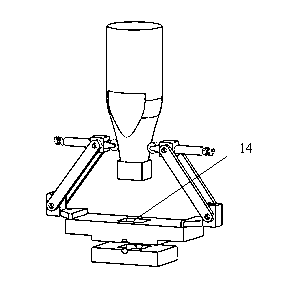

[0031] Such as Figures 1 to 7 As shown, a common press block forging mold base includes a mold base bracket 11, a die forging punch 1 that can reciprocate up and down through the upper end of the mold base bracket 11, and the mold base bracket 11 is also provided with a die Clamping mechanism and side pressing mechanism driven by forging punch 1.

[0032] The mold clamping mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com