Biaxial orientation plastic tube manufacturing method and apparatus

A technology of biaxial orientation and plastic pipes, which is applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems that the tube blank cannot pass through, unfavorable biaxial orientation pipes, and difficult operation, so as to ensure the service life and implement Simple, uniform radial orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

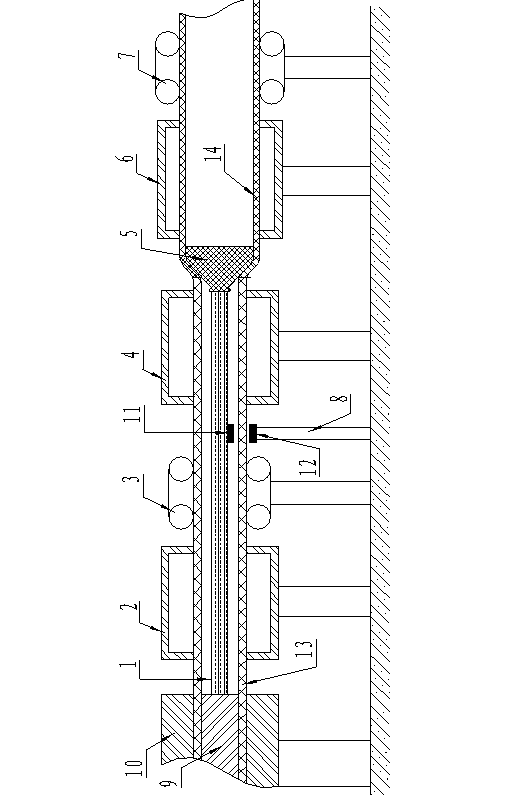

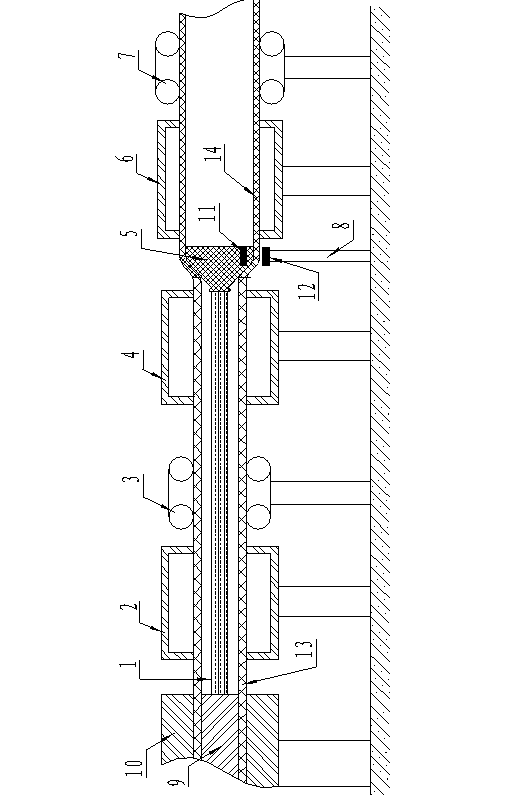

[0019] figure 2 In another embodiment of the device of the present invention, the elastic magnetic block 11 is arranged on the tapered diameter expansion head, and the magnetic receiving frame 12 has the same magnetic poles as the elastic magnetic block 11, and is located in the elastic magnetic block 11. , And corresponding to the position of the elastic magnetic block 11. The molten plastic pipe material passes through the gap between the die 10 of the plastic pipe extruder and the mandrel 9 to extrude the tube blank 13, and the tube blank 13 is cooled by the first stage of vacuum shaping and cooling 2, the first tractor 3 enters the heating box 4 After being heated to a highly elastic state, the biaxially oriented plastic pipe 14 is produced by the conical expanding head 5, the second-stage vacuum shaping cooling box 6 and the second tractor 7, in which the two tractors maintain a speed ratio of 1.1 to 3.0, The speed of the second tractor 7 is greater than that of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com