Adhesive film bonding equipment and adhesive film bonding method

A laminating equipment and adhesive film technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as peeling off, circuit boards and hot-melt films are easy to fall off, and achieve the effect of strengthening the mechanical bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

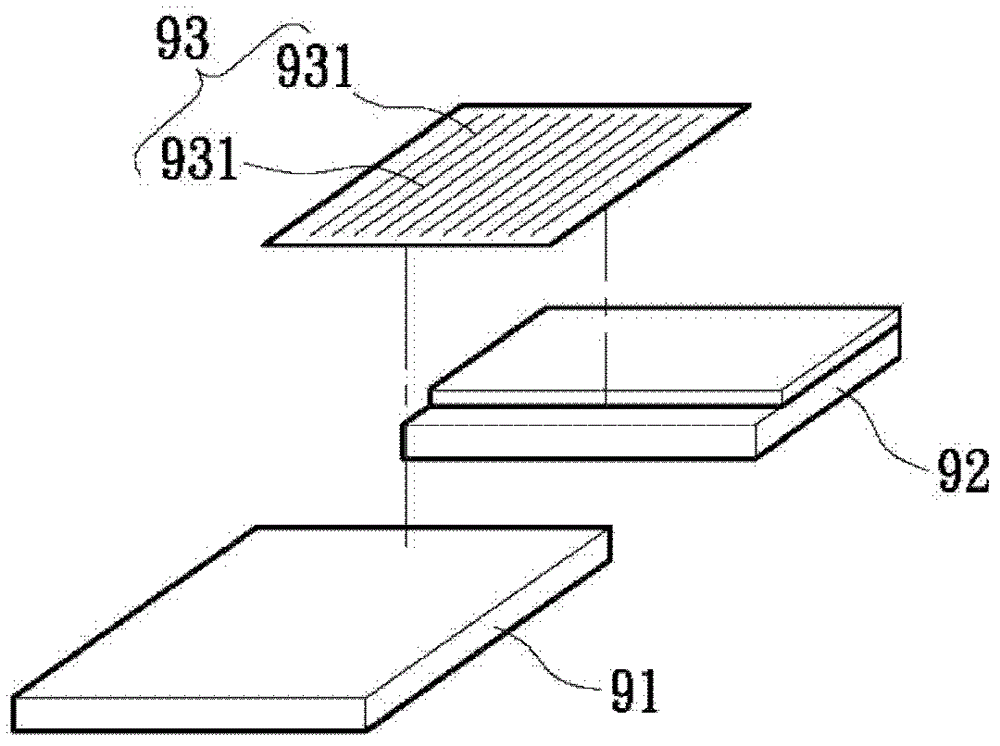

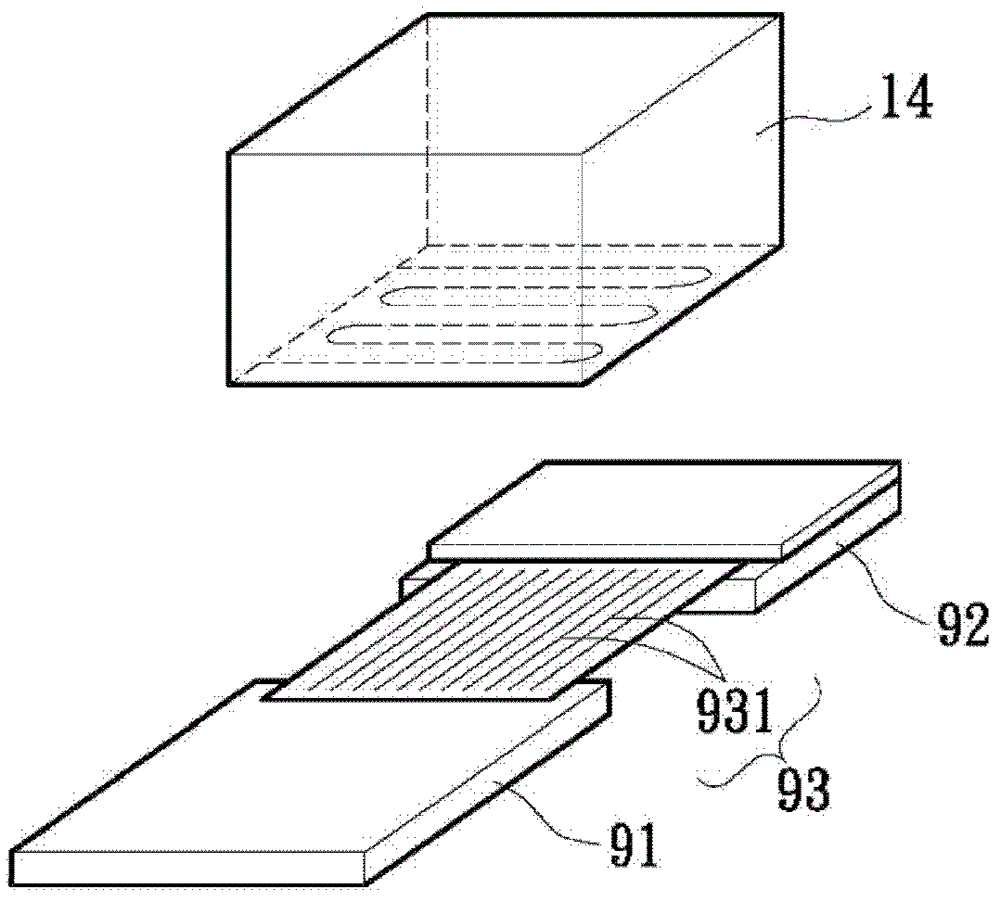

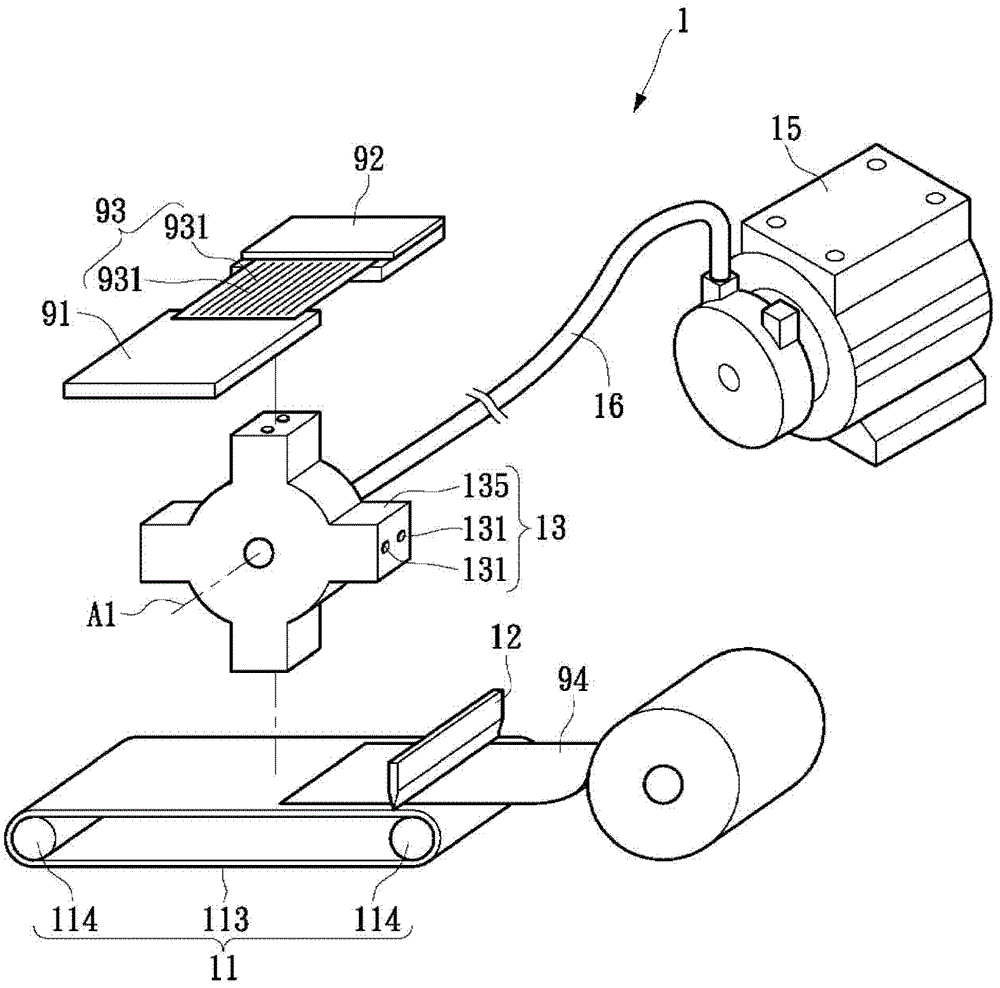

[0024] see figure 1 , figure 1 It is a schematic diagram of the circuit board and the hot melt film before lamination. Such as figure 1 As shown, a circuit board 91 and an electronic component 92 intend to achieve the purpose of electrical coupling through a hot melt film 93 (Hot Melt Film, HMF); wherein, the circuit board 91 and the electronic component 92 achieve After being electrically coupled, people can control and drive the electronic components 92 through the circuit board 91 . Here, the electronic components 92 can be electronic and circuit assemblies with software / hardware execution functions such as liquid crystal panels and solar panels, or other different types of main boards, control panels, or even other buses and control chips. , control unit and other smaller electronic components; here, the present invention does not limit the type and size of the electronic components 92 . Generally speaking, when the circuit board 91 is coupled with the electronic compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com