A kind of diamond flexible abrasive belt with equal wear structure and manufacturing method thereof

A production method and diamond technology, applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of easy falling off of diamonds, narrowing of the width of the abrasive belt, affecting the service life of abrasive tools, etc., so as to improve the mechanical bonding strength and reduce falling off. possibility, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

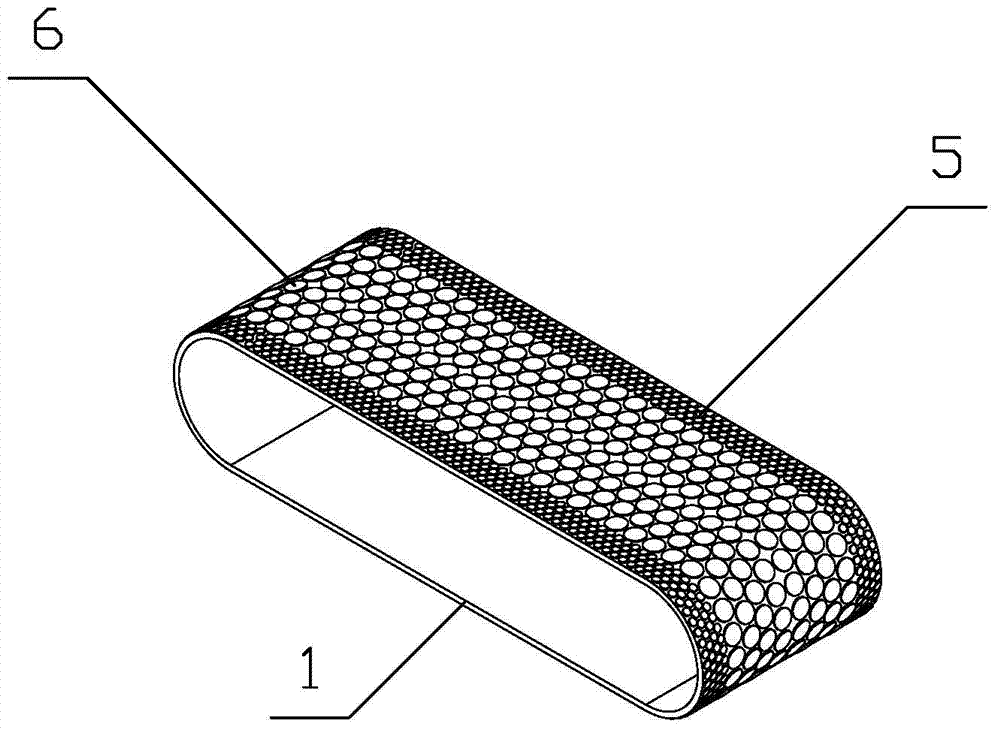

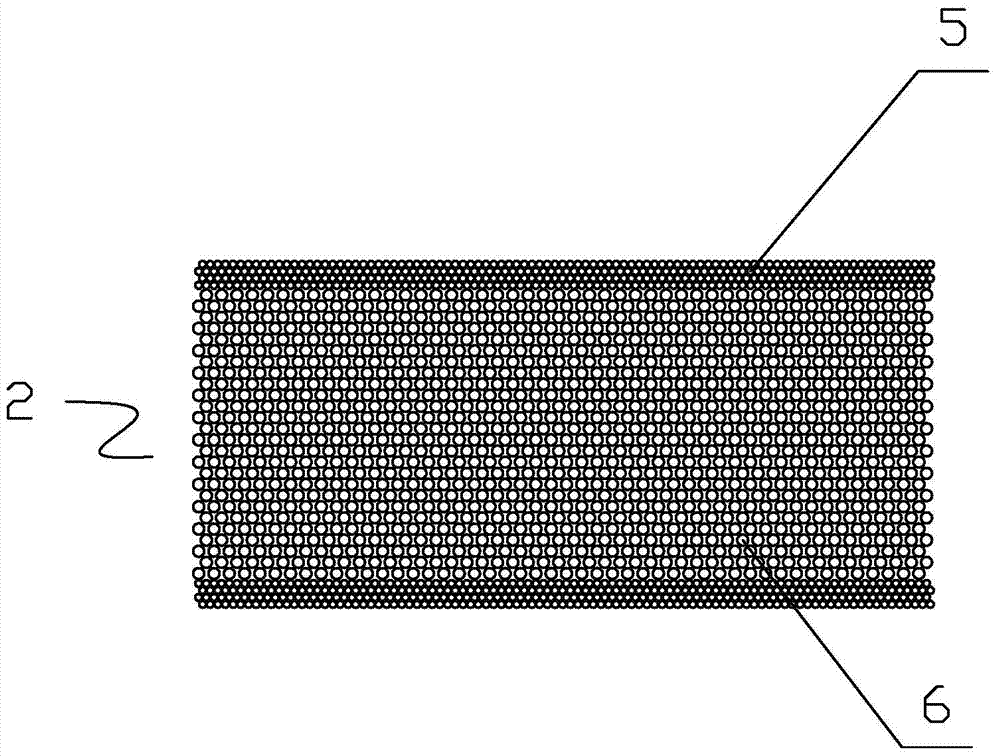

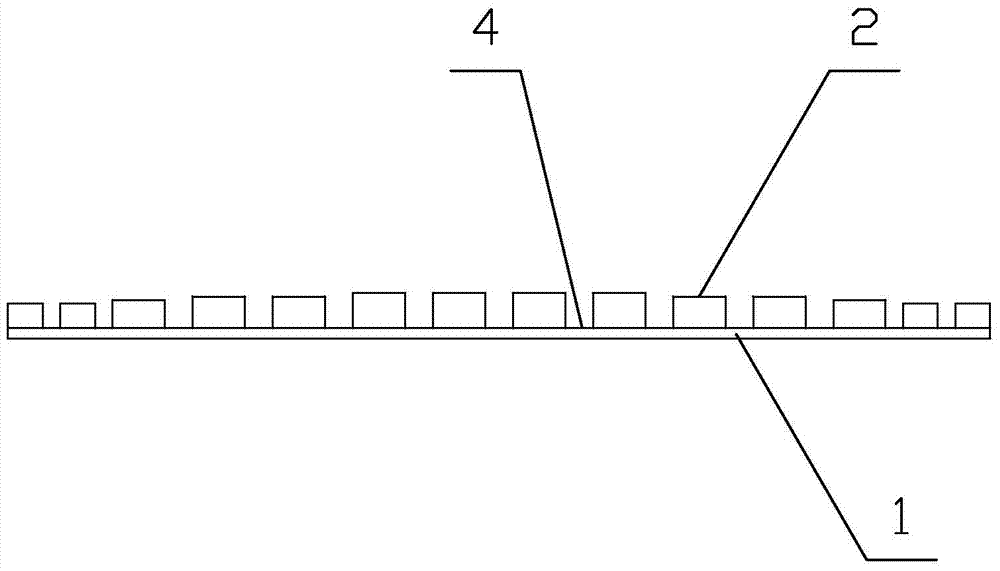

[0028] A diamond flexible grinding belt with equal wear structure, which can be connected end to end to form an endless belt, which includes a base body 1 and a grinding working layer 2, the base body 1 is provided with a number of fine holes 3, the base body 1 Electrodeposited metal coating 4 is formed by electrodeposition in the surface and pores 3 holes; the grinding working layer 2 is composed of several superhard fine particles 5 and superhard coarse particles 6 fixed on the electrodeposited metal coating 4; The ultra-hard fine particles 5 are evenly distributed on the surface of the left and right edge parts of the electrodeposited metal coating 4, and the super-hard coarse particles 6 are evenly distributed on the surface of the middle part of the electrodeposited metal coating 4, forming dense edges at both edges. And ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com