Electroslag remelting furnace

A technology of electroslag remelting furnace and electrode clamp, which is applied in the field of electroslag smelting equipment, can solve the problems of reducing the height of the plant, and achieve the effects of reducing the height of the plant, less interference, and ensuring high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

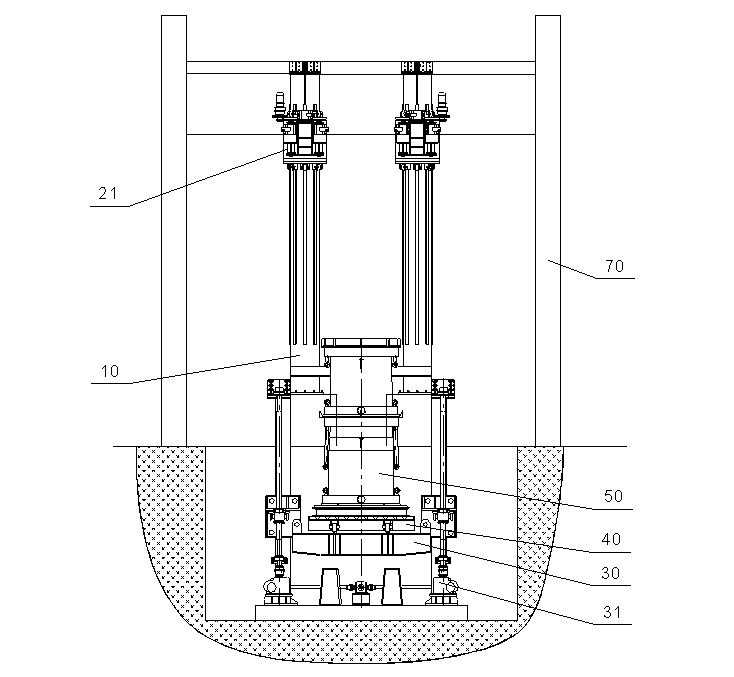

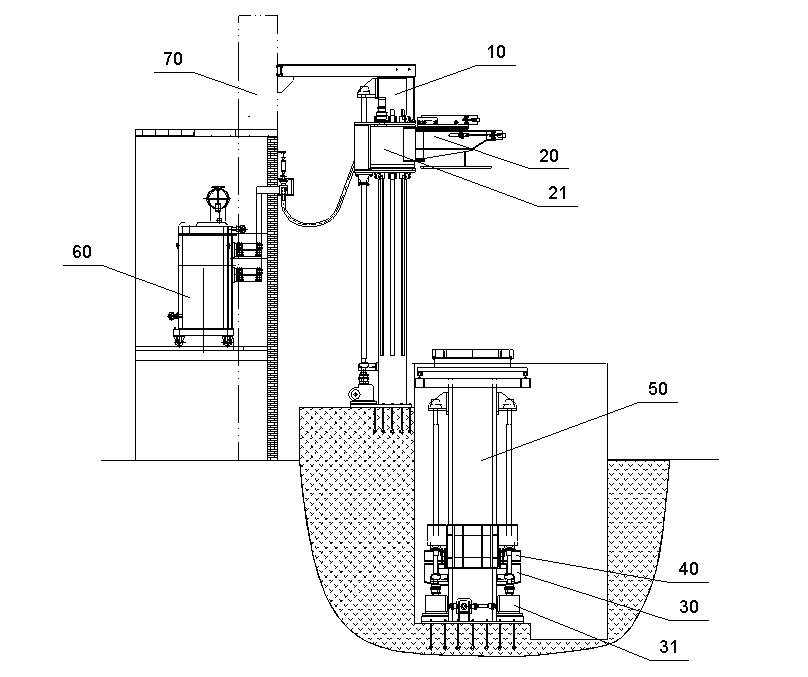

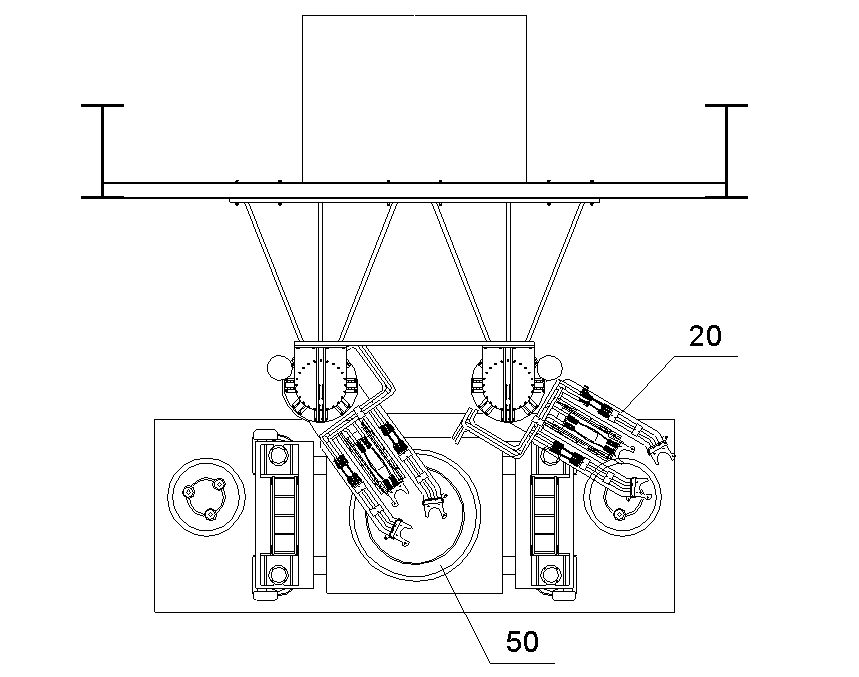

[0031] An electroslag remelting furnace, such as Figure 1 to Figure 8 Shown, comprise lifting platform 30 and the platform lifting device 31 that drives lifting platform 30 to move up and down, lifting platform 30 is provided with motorized flat car 40, and motorized flat car 40 top is provided with crystallizer 50, and described platform lifting device 31 is provided with There are two columns 10, each column 10 top is provided with a cross arm 20, and the cross arm 20 is connected with the column 10 through a connection device 21, and the connection device includes a rotary device that can drive the cross arm 20 to rotate around the axis of the column 10 and A lifting device that moves axially along the column. The free end of the cross arm 20 is provided with a chuck 22 for clamping the electrode. The chuck 22 includes a base 221 and three in- Support arms 222 side by side on the same horizontal plane, each end of support arm 222 is provided with an electrode holder, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com