Heat exchange separator capable of preparing ice crystals and salt crystals simultaneously by utilizing seawater

A heat separator and salt crystal technology, which is applied in the field of heat exchange separators, can solve problems such as the limitation of application scope, and achieve the effects of improving the effective utilization rate, expanding the field, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

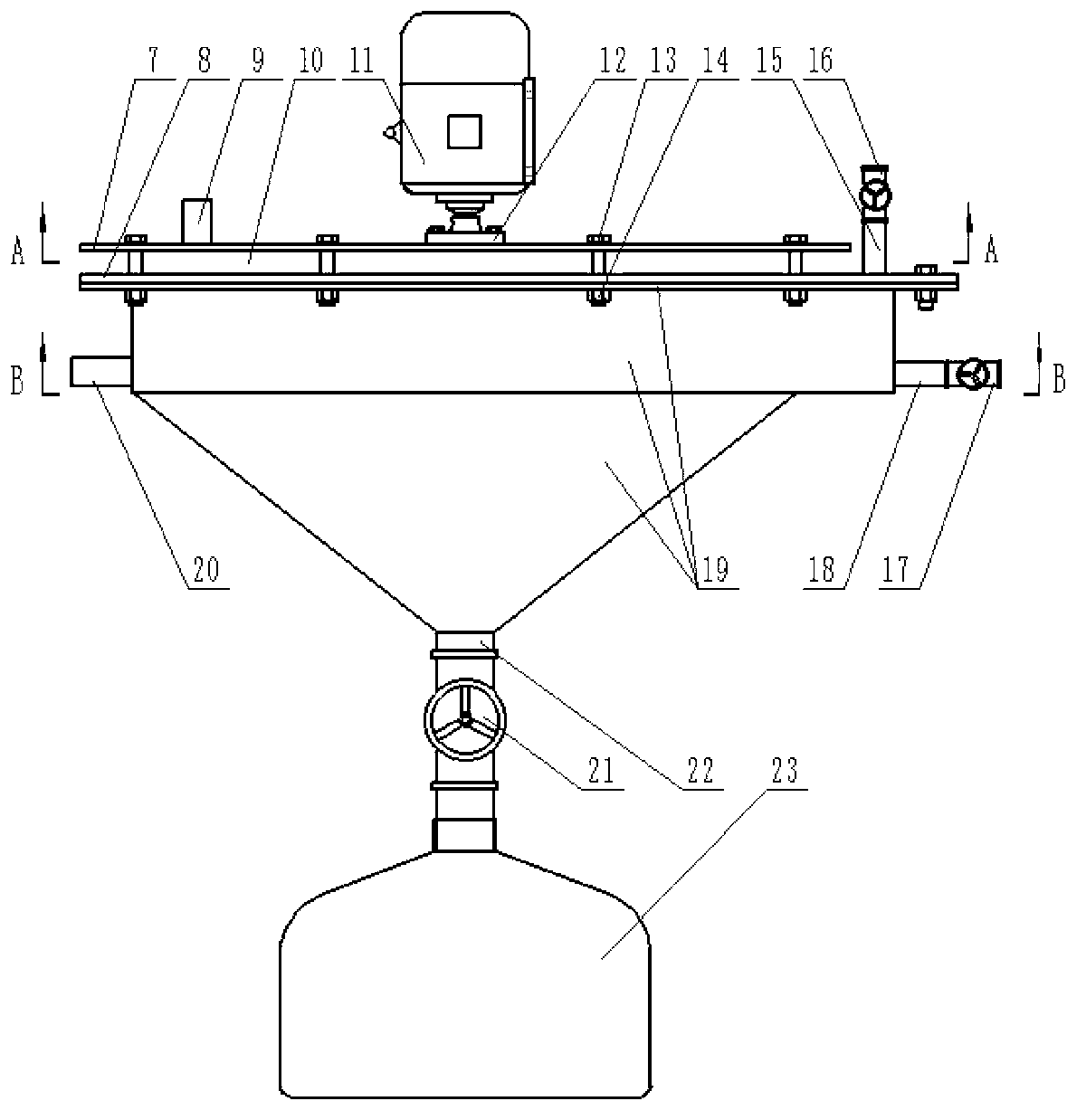

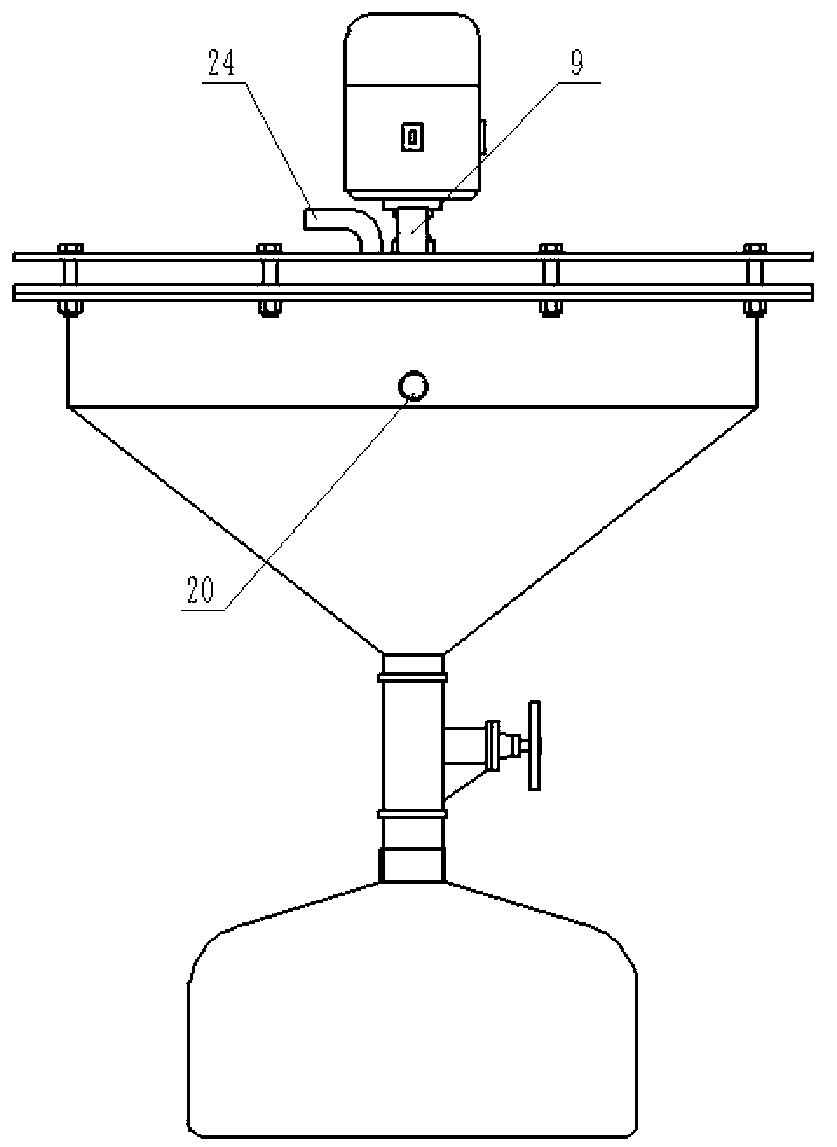

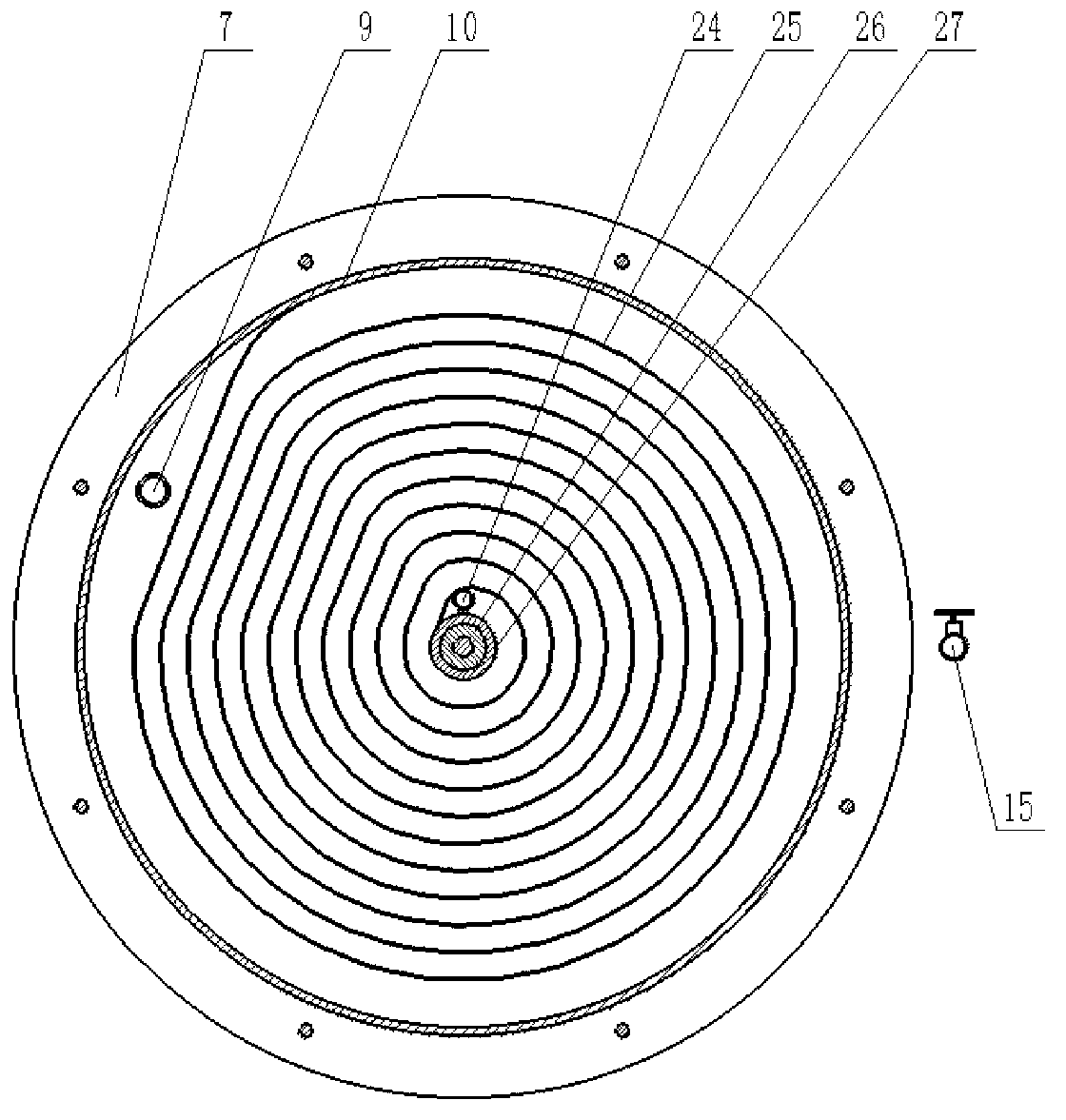

[0024] The schematic diagram of the heat exchange separator for simultaneously preparing ice crystals and salt crystals by using seawater in the present invention is as follows Figure 1-Figure 4 As shown, it includes a closed refrigerant evaporation component, an ice scraper motor 11, an ice scraper 28, a shell 19, and a salt crystal collection container 23. The top of the shell 19 is connected with the refrigerant evaporation component, and the shell 19 The lower part is cone-shaped, and the lower part of the shell 19 is connected to the salt crystal collection container 23 through a salt crystal outlet nozzle 22 and a salt crystal collection control valve 21. The ice scraper 28 is mounted on the output shaft of the ice scraper motor 11, and the ice scraper is mounted on the top of the housing and contacts the ice crystal crystallization portion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com