Drying roller for stripping machine

A technology of steam stripper and drying roller, which is applied in the direction of drying chamber/container, dryer, etc., which can solve the problems of PE separator manufacturers such as increasing economic costs, limiting the length range of drying rollers, and small production capacity, so as to avoid shaft The fatigue load of the head is increased, the seal is guaranteed, and the effect of good centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

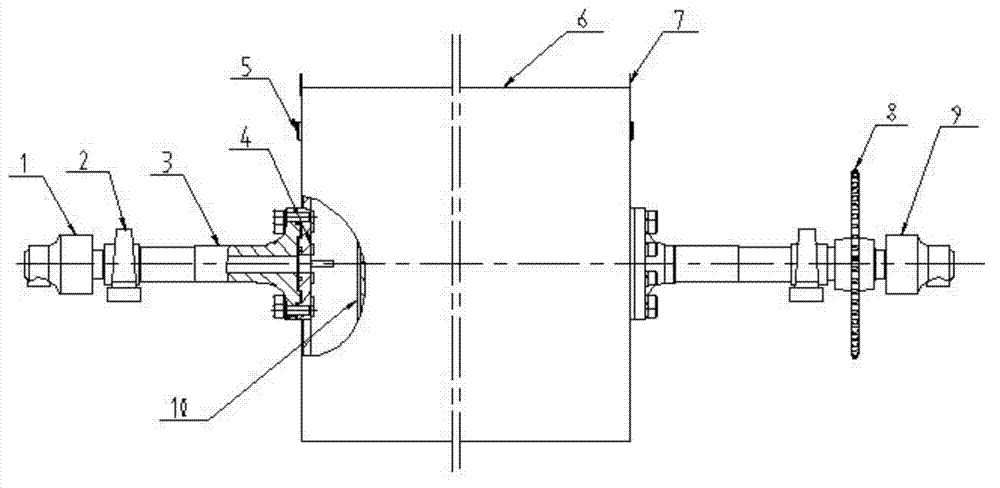

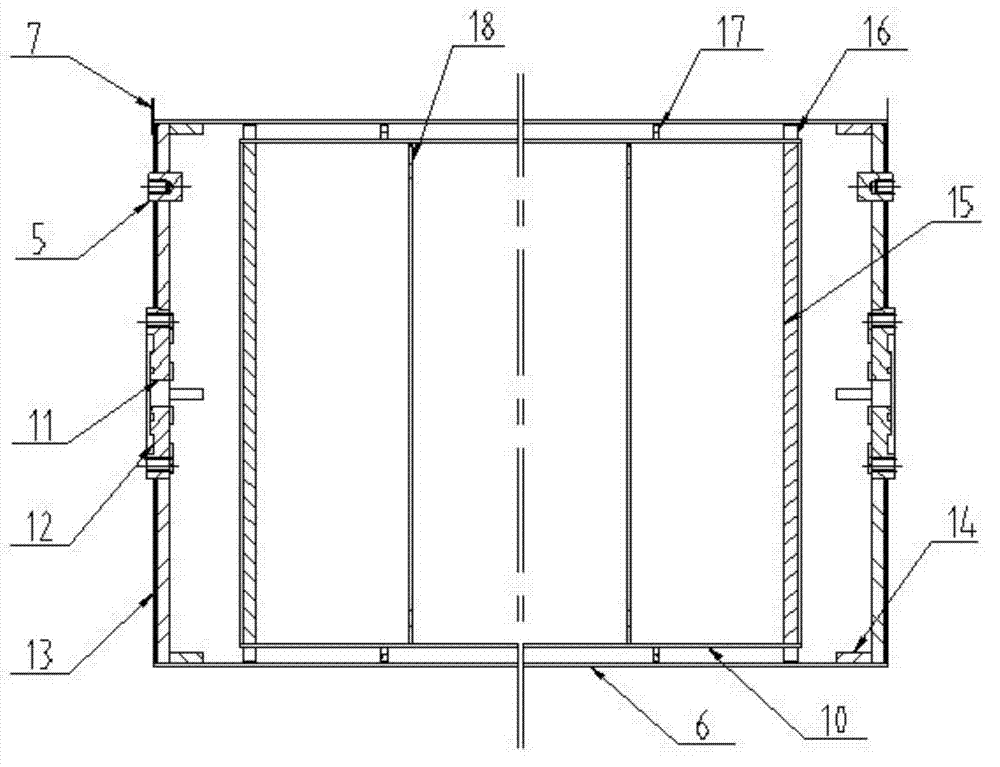

[0025] The drying roller for the stripper mainly includes an outer cylinder 6, an inner cylinder 10, a water inlet end, a water outlet end and a supporting device, and is used for drying the PE separator of the storage battery.

[0026] Such as figure 1 As shown, the outer cylinder 6 is a cylinder structure with end caps at both ends. The outer cylinder 6 is made of alloy material, and the outer diameter of the outer cylinder 6 is 800 millimeters, the thickness is 8 millimeters, and the length is 1.75 meters. Two circles of reinforcement rings 17 surrounding the circumference of the inner wall of the outer cylinder are welded inside the outer cylinder 6 . Four positioning blocks 8 evenly distributed around the circumference of the inner wall of the outer cylinder are welded at the joint between the inner cylinder body and the end cap of the outer cylinder 6 .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com