Tester used for testing fluid resistance height of proppant and testing method thereof

A test method and proppant technology, applied in instruments, measuring devices, liquid level indicators, etc., can solve the problems of complex equipment and cumbersome test process, and achieve the effect of simple test process, less test equipment and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

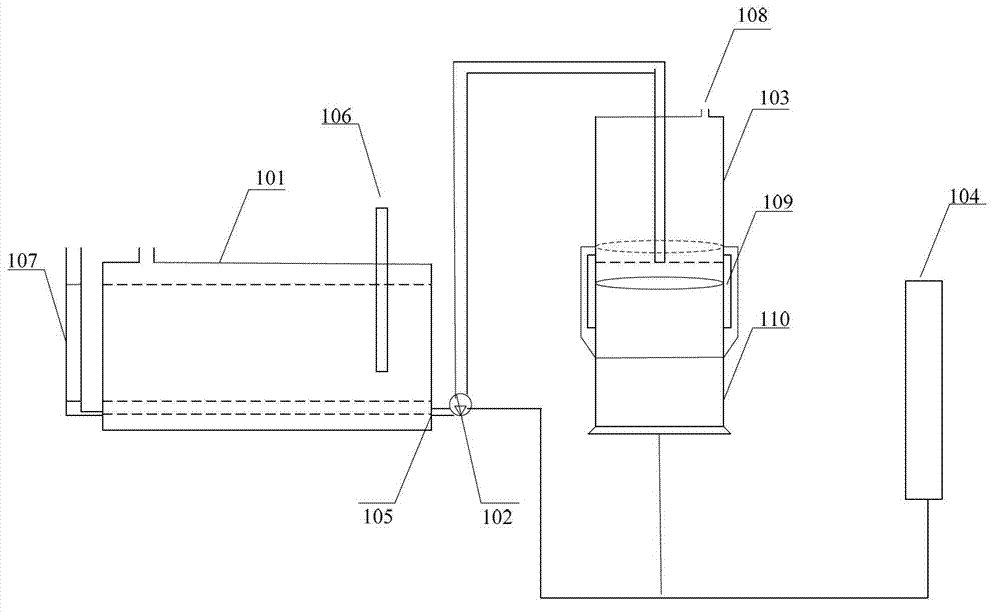

[0030] Embodiment one, see figure 1 , a tester for detecting the liquid resistance height of the proppant of the present invention, the tester includes:

[0031] The first liquid storage tank 101, the inside of the first liquid storage tank 101 is provided with a thermometer 106 for measuring the temperature of the test liquid in the first liquid storage tank 101; The liquid level indicator 107 is used to display the liquid level in the first liquid storage tank 101 . A thermometer 106 is set in the first liquid storage tank 101 to obtain the temperature of the test liquid, so as to measure the liquid resistance performance of the proppant to test liquids of different temperatures; a liquid level indicator 107 is set to display the temperature of the first liquid storage tank 101, in order to timely adjust the liquid level height in the first liquid storage tank 101, to avoid the liquid level is too high test liquid overflow or the liquid level is too low to pump gas into the...

Embodiment 2

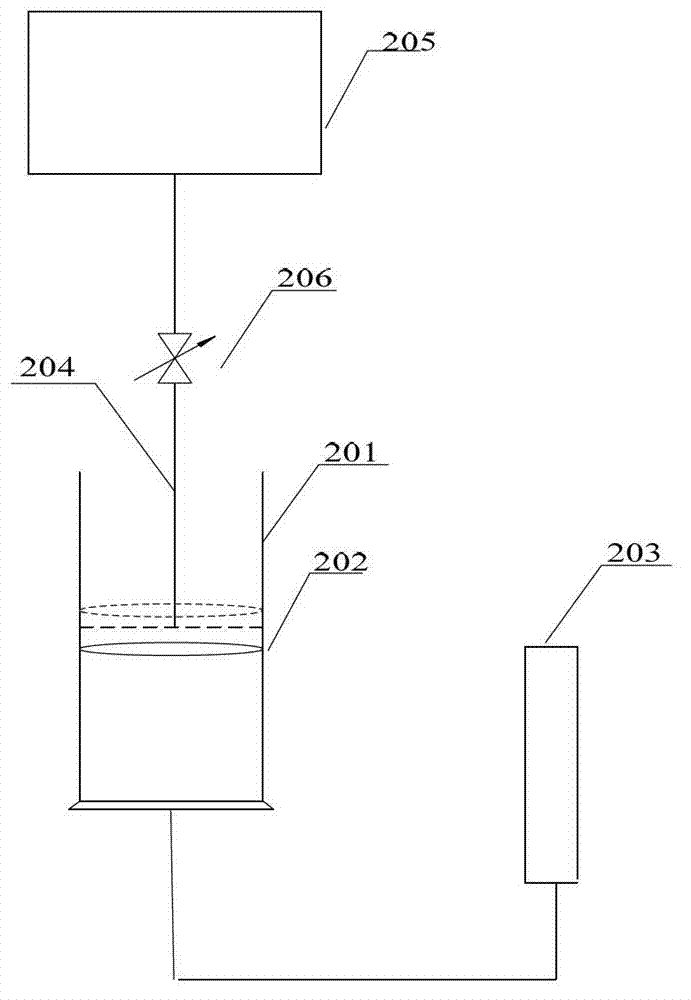

[0046] Embodiment two, see figure 2 Shown:

[0047] A tester for detecting the liquid blocking height of the proppant of the present invention comprises:

[0048] The second liquid storage tank 205, the outer wall of the second liquid storage tank 205 is made of transparent material, and the height scale is engraved on the outer wall, the liquid storage volume in the second liquid storage tank can be observed in real time, so as to adjust in time The amount of liquid stored in the second liquid storage tank 205 is to prevent the liquid level in the second liquid storage tank 205 from overflowing when the liquid level in the second liquid storage tank 205 is too high or the gas injected into the measuring device when the liquid level is too low.

[0049] A liquid inlet device, the liquid inlet device is provided with a valve 206 and a liquid outlet pipe 204, and the liquid outlet end of the liquid outlet pipe extends into the vicinity of the top of the charging part. The liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com