Shield tunnel excavation surface stability centrifuge model test matching apparatus

A technology of centrifugal model testing and shield tunneling, applied in the direction of measuring devices, strength characteristics, instruments, etc., to achieve good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

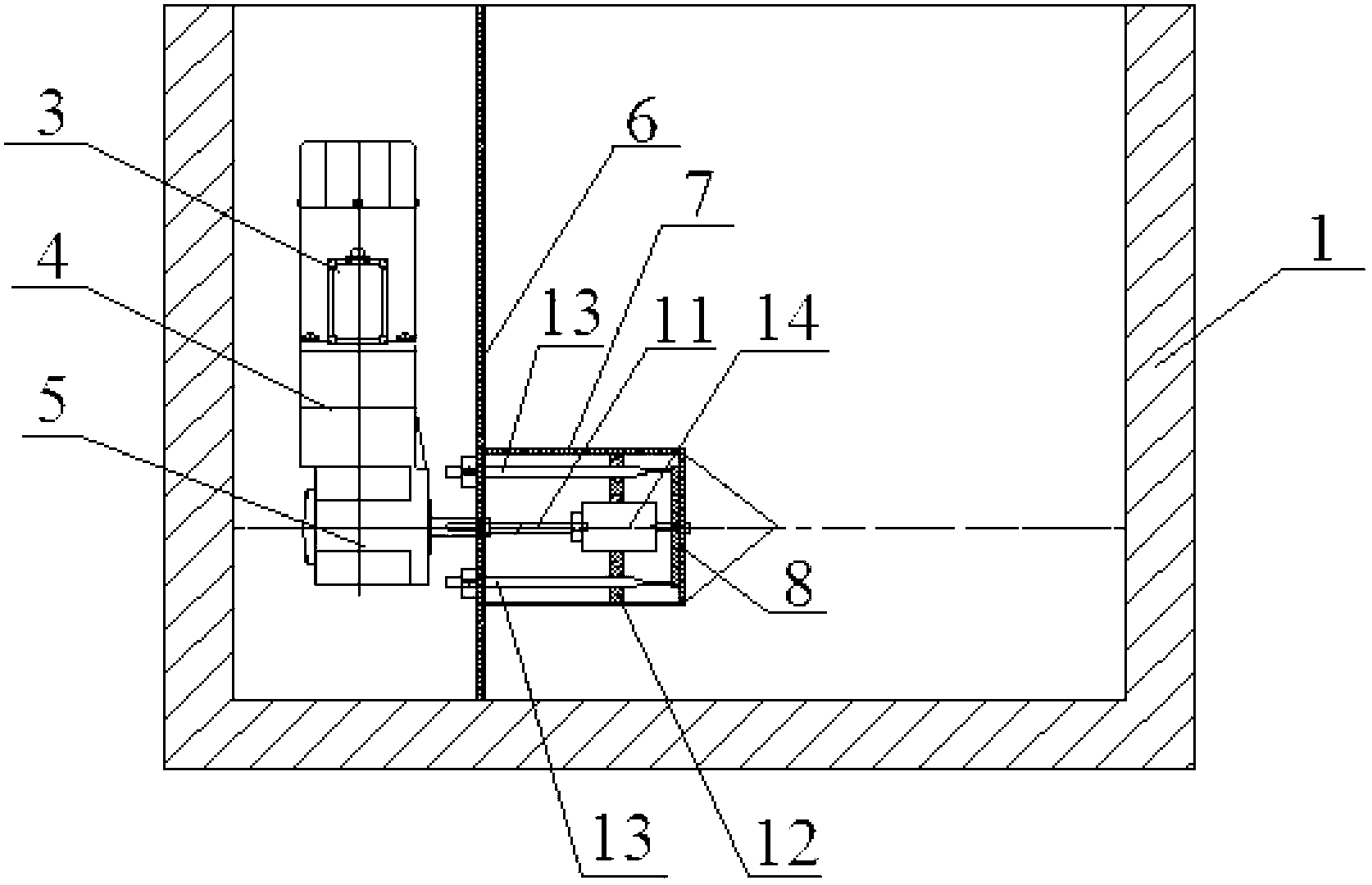

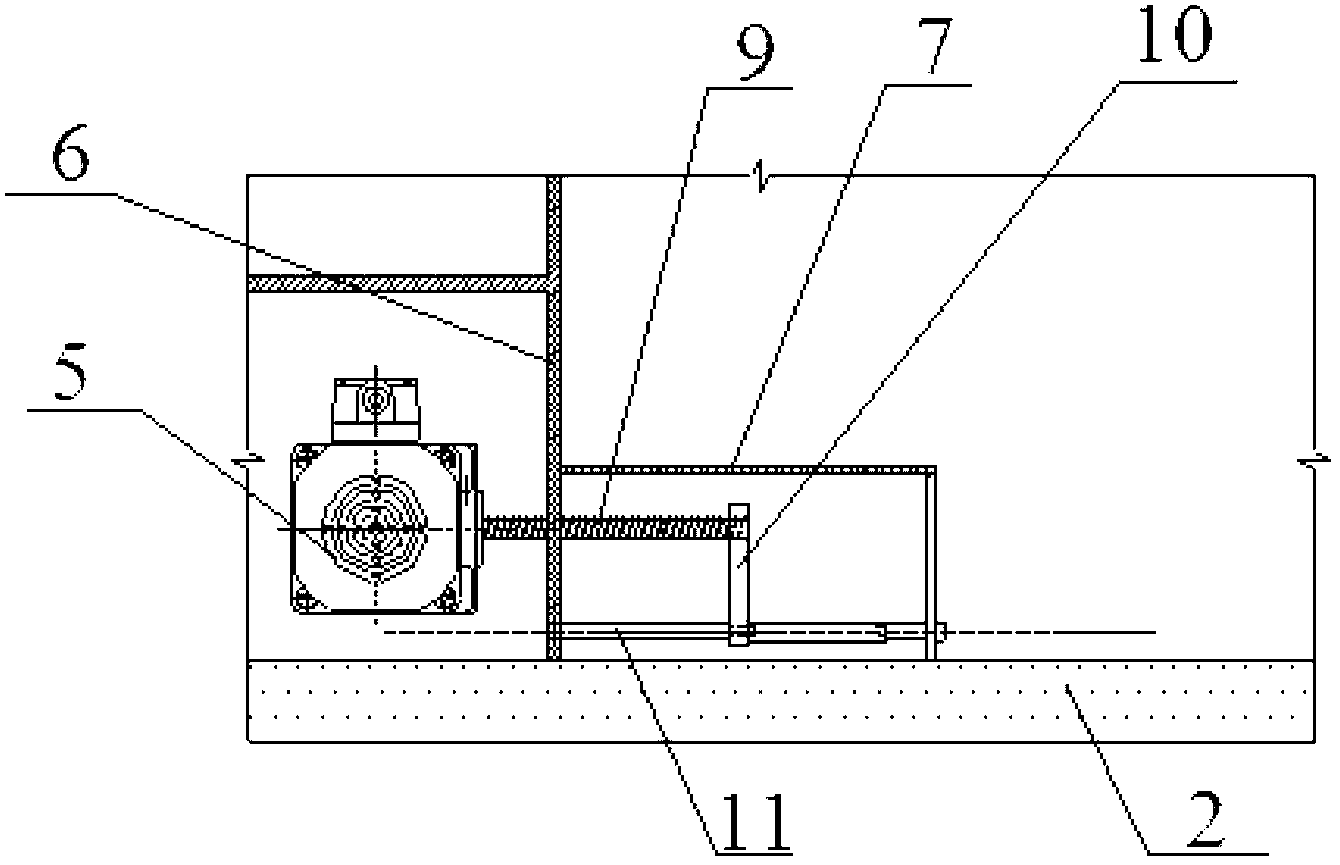

[0040] A supporting device for the centrifugal model test of the excavation face stability of a shield tunnel, such as Figure 1 to Figure 5As shown, the model box 1 is included, the front side of the model box 1 is a plexiglass window 2, the upper side of the model box 1 is provided with an opening, the model box 1 is located in the centrifugal testing machine, and the model box 1 is provided with a model tunnel 7, Tunnel rigid support surface 8, power components, transmission components and data acquisition components. Among them, the model tunnel 7 is located in the model box 1, and the outside of the model tunnel 7 is filled with test foundation soil; the rigid support surface 8 of the tunnel is set on the top of the inside of the model tunnel 7; the power component is set on the outside of the model tunnel 7, and the power component includes The connected three-phase asynchronous motor 3, continuously variable transmission 4 and worm gear reducer 5; the transmission assem...

Embodiment 2

[0052] The inner diameter of a large-diameter shield tunnel is 15m, the buried depth ratio is about 1, and the foundation soil is divided into sandy soil layers. It is necessary to conduct centrifugal model test research on the process of soil instability and destruction due to insufficient support pressure on the shield excavation face, and obtain relevant data.

[0053] For such problems, follow the Figure 1 ~ Figure 2 Satisfactory results can be achieved by adjusting the output speed of the displacement control system and determining the parameters of the foundation soil according to the actual situation of the project and geological conditions.

[0054] The test uses Tongji University TLJ-150 composite rock and soil centrifugal testing machine, and the internal size of the model box 1 is 900mm×700mm×700mm (length×width×height). The centrifugal acceleration is 100g during the official test. Therefore, the inner diameter of the model tunnel 7 is 150 mm. The earth pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com