Method for fast and accurately realizing concrete pump truck cantilever crane movement locus

A concrete pump truck and boom technology, which is applied to instruments, adaptive control, control/adjustment systems, etc., can solve the problems of complicated planning process of the movement trajectory of the boom end, cumbersome calculation, large amount of calculation, etc. Control, simple calculation process, fast algorithm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The invention discloses a method for quickly and accurately realizing the movement trajectory of the arm frame of a five-section arm concrete pump truck. The specific steps are as follows:

[0036] step 1:

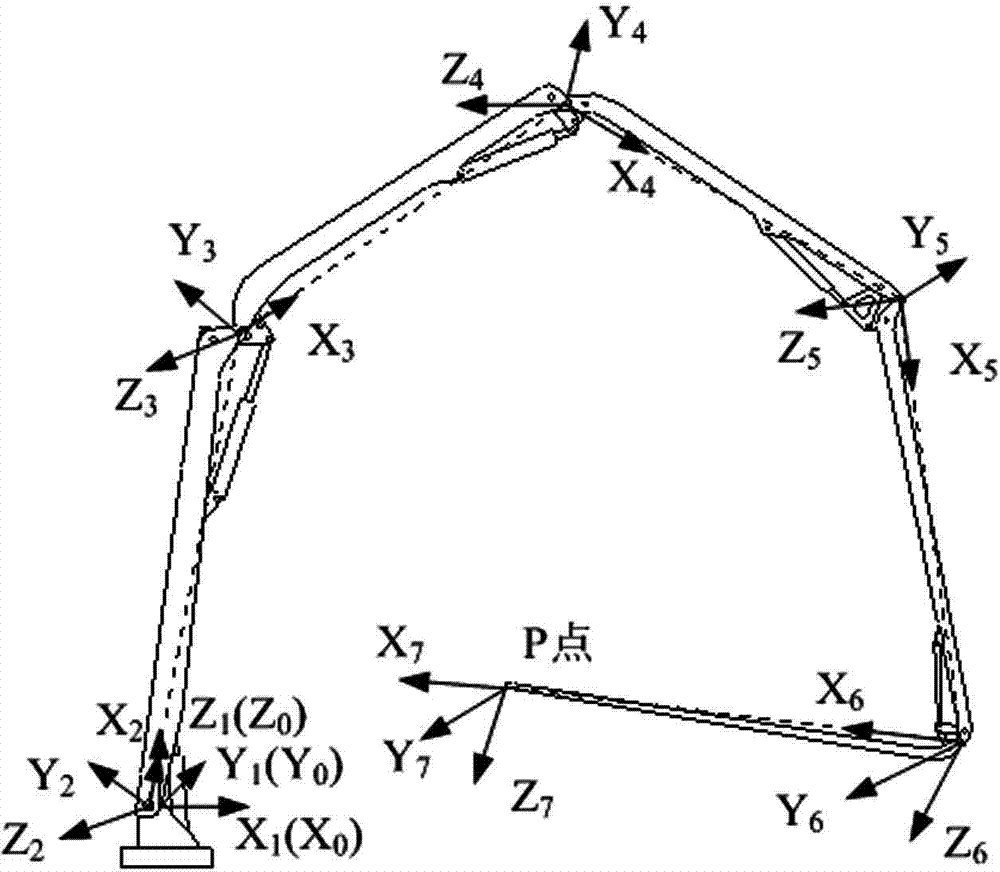

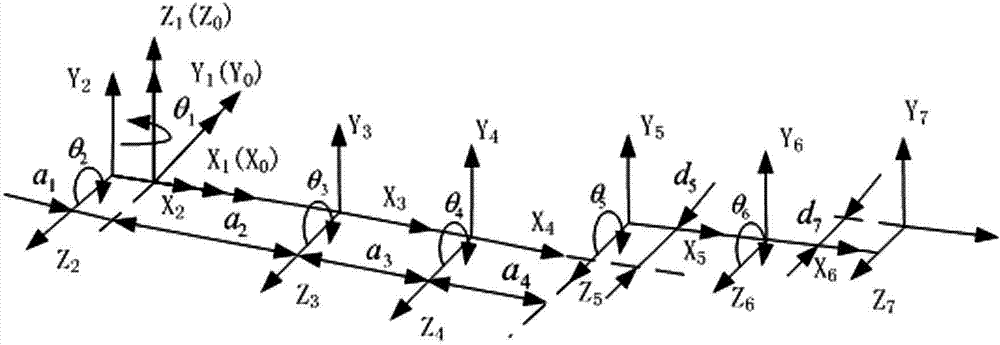

[0037] Establish the boom system coordinate system model. According to the structural model of the arm frame system of the five-section arm concrete pump truck, the joint coordinate system of the arm frame mechanism of the concrete pump truck is established, as shown in figure 1 As shown, a total of seven joint coordinate systems are established, and the pouring end of the boom is marked with point P, and its coordinates are (x 7 ,y 7 ,z 7 ). Measure the structural size of the boom to obtain the connecting rod parameters of the D-H matrix, as shown in Table 1.

[0038] Step 2:

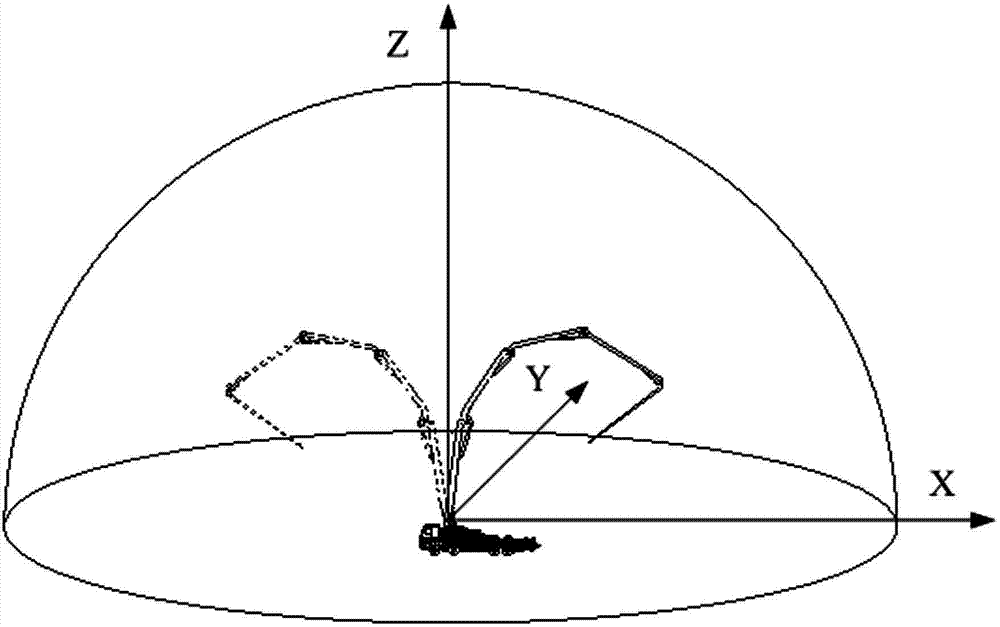

[0039] Solve for the coordinates of P at the pouring end of the jib. Analysis of the jib coordinate system and connecting rod parameters shows that the coordinates of point P at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com