Adjustable limiting ring used for plasma processing device

A processing device and plasma technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of non-uniformity, non-uniformity, and non-uniformity of the substrate process in the process area, so as to improve the process area asymmetry. , Improve the effect of process uniformity problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

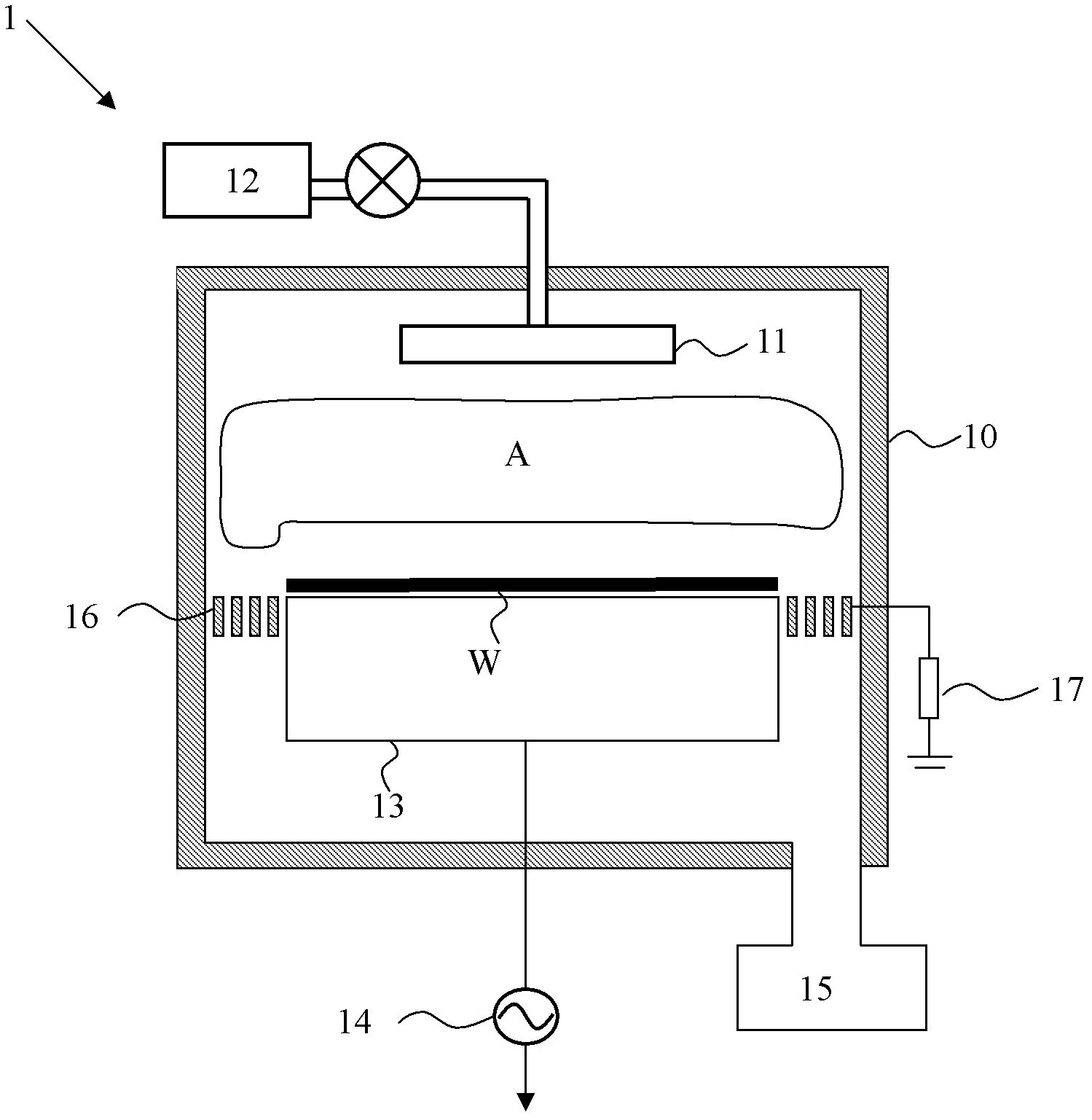

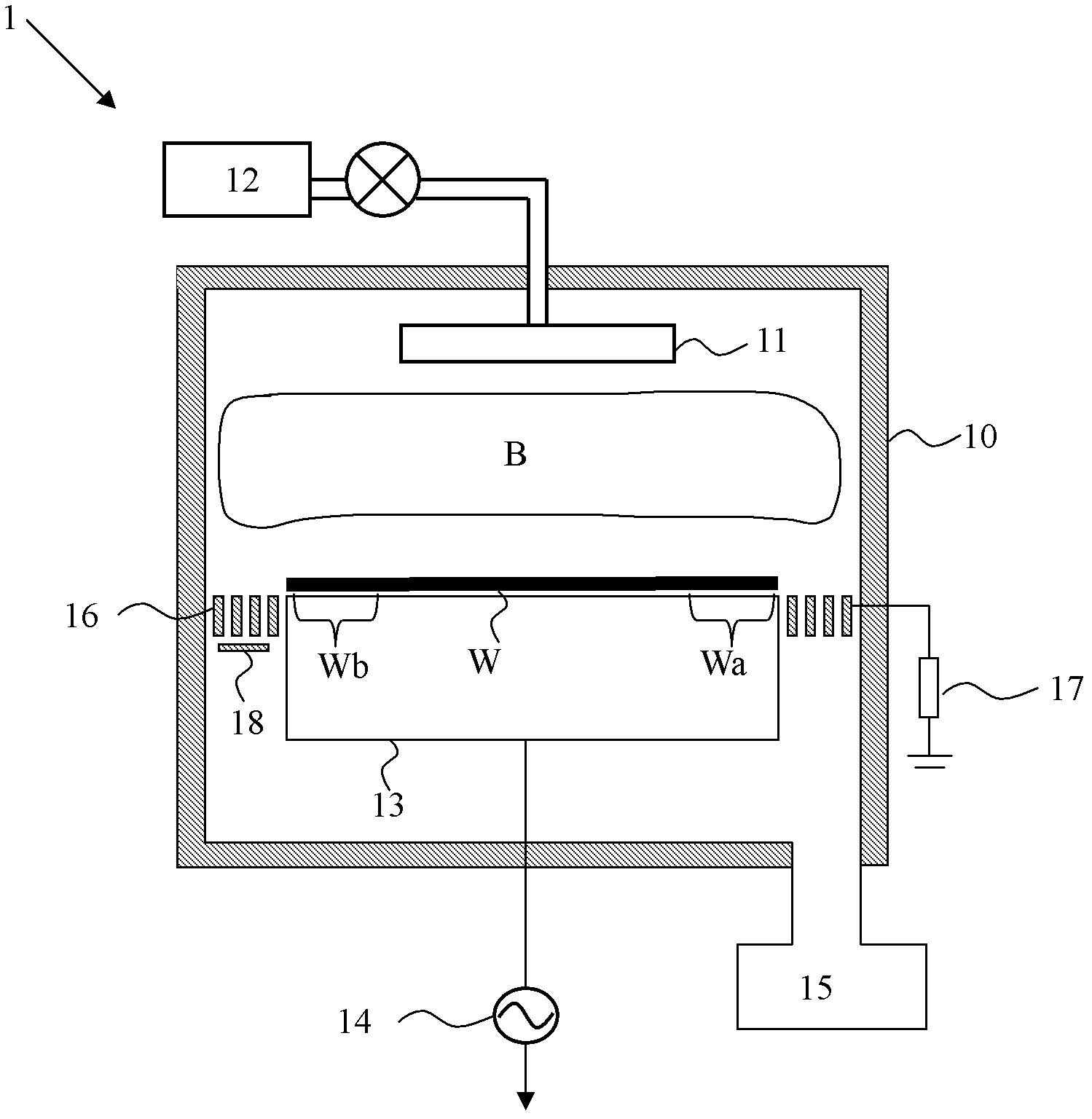

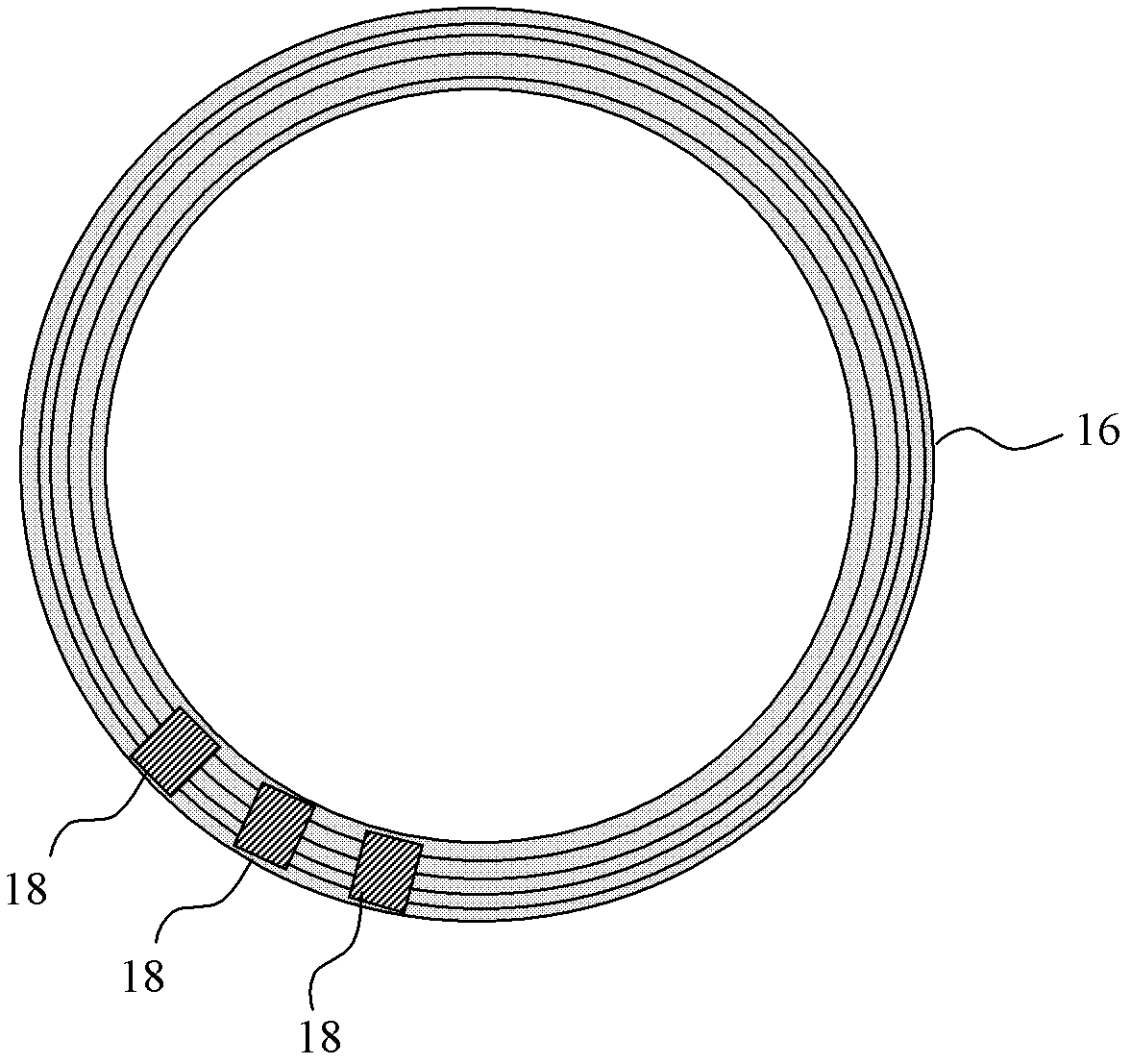

[0027] The invention mechanism of the present invention is to set at least one baffle under the corresponding confinement ring in the part of the processing area where the plasma concentration is low, so as to limit the flow velocity of the plasma flowing out of the cavity and improve the plasma processing area. The non-alignment ensures the uniformity of the substrate process here and other regions of the substrate. figure 1 Shows the process area in the plasma processing apparatus before using the present invention, such as figure 1 As shown, because it exemplarily directly or indirectly grounds the confinement ring on the right side of the illustrated chamber, the process region A near this ground (the left side of the illustrated plasma processing apparatus) is "dragged ” is higher, and the plasma concentration is lower than that on the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com