Wafer to wafer connection structure

A technology of bonding structure and wafer, applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve problems such as inability to align

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

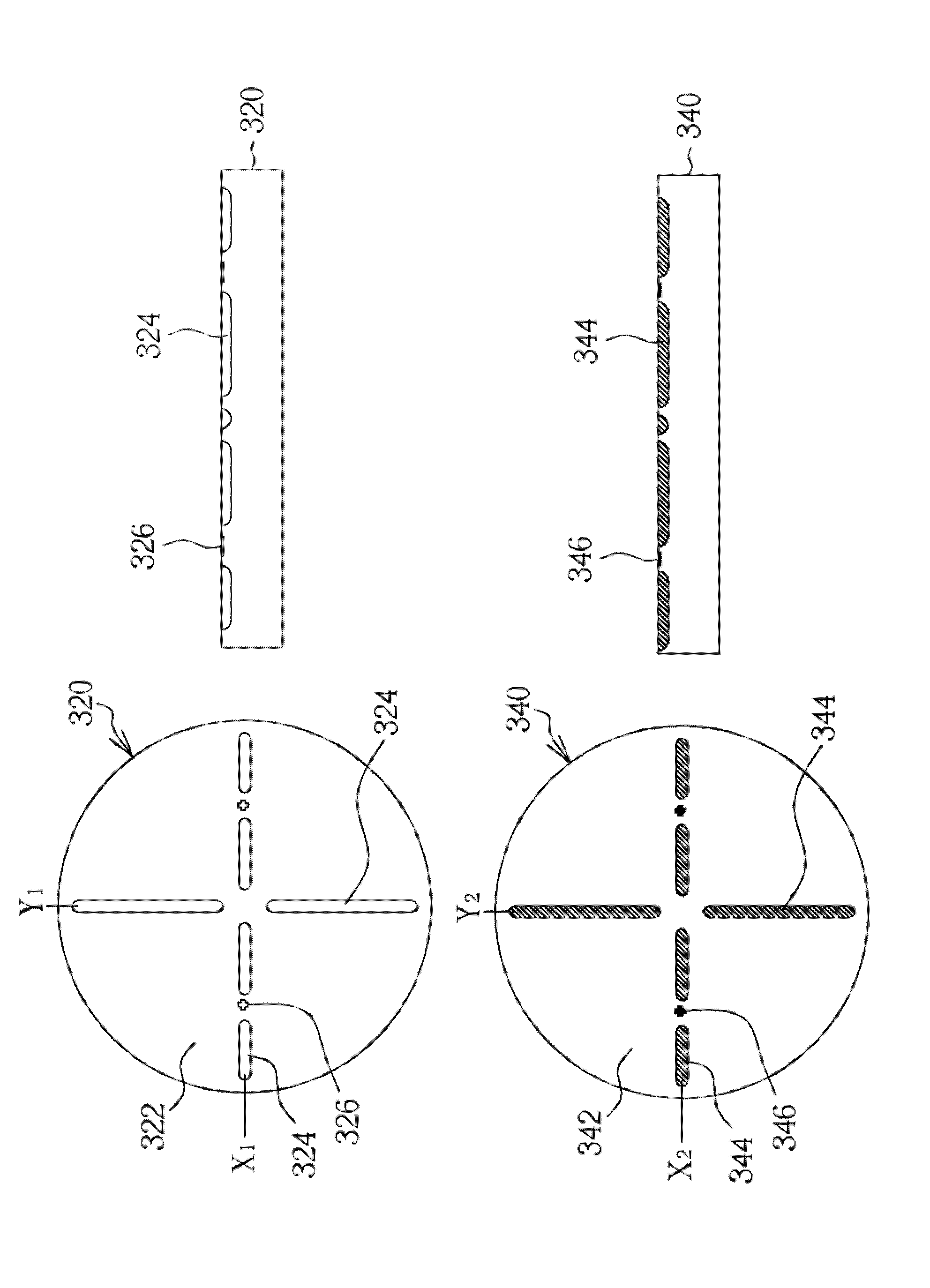

[0031] now refer to image 3 , which depicts a top view and a cross-sectional view of two first wafers and second wafers to be docked before bonding according to an embodiment of the present invention. Such as image 3 As shown, the wafer-to-wafer bonding structure of the present invention is formed by bonding a first wafer 320 and a second wafer 340 . The first chip 320 has a first surface 322 on which a plurality of first grooves 324 and various components and circuits (not shown) are disposed. In this embodiment, more than one first groove 324 may be respectively provided on the transverse diameter X1 and the longitudinal diameter Y1 of the first wafer 320 . Wherein, the first trench 324 provided on the lateral diameter X1 of the first wafer 320 has a length parallel to the lateral diameter X1 and a width parallel to the longitudinal diameter Y1, and the groove 324 provided on the longitudinal diameter Y1 of the first wafer 320 The first trench 324 has a length parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com