Triamcinolone biodegradable maltose microneedle array and preparation method thereof

A technology of microneedle array and triamcinolone acetonide, which can be used in drug delivery, drug combination, and pharmaceutical formulation, and can solve problems such as unbearable pain, imbalance, and multi-point injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example 1 Preparation of triamcinolone acetonide biodegradable maltose microneedle array by stepwise controlled pulling method

[0083] (1) Dissolve 10 mg of commercially available maltose powder and 10 μL of deionized water at 110°C for 10 min, then spread the liquid maltose on a circular stainless steel substrate, and quickly add 1 mg of triamcinolone acetonide (Tianjin Pacific Chemical Pharmaceutical Co., Ltd.) powder , mix evenly, cool down to 103°C and spread the mixture to a thickness of 122±13.5μm.

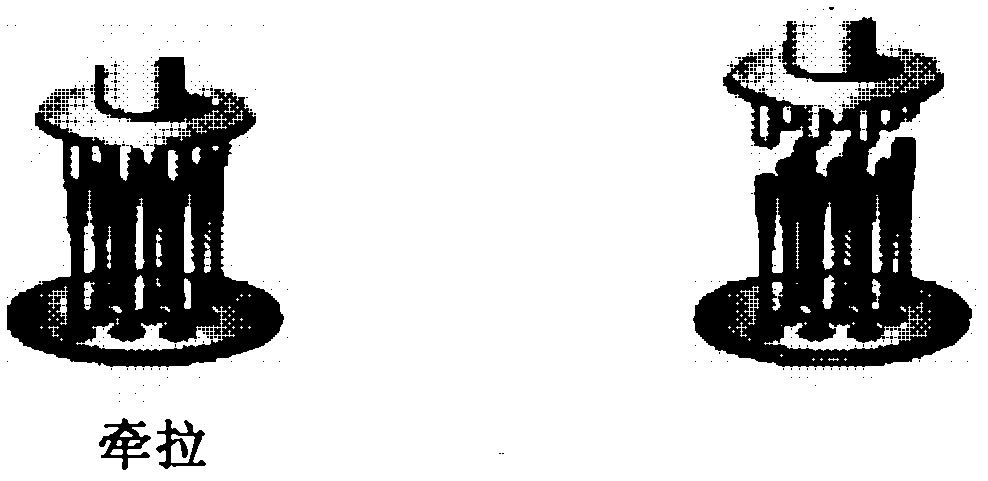

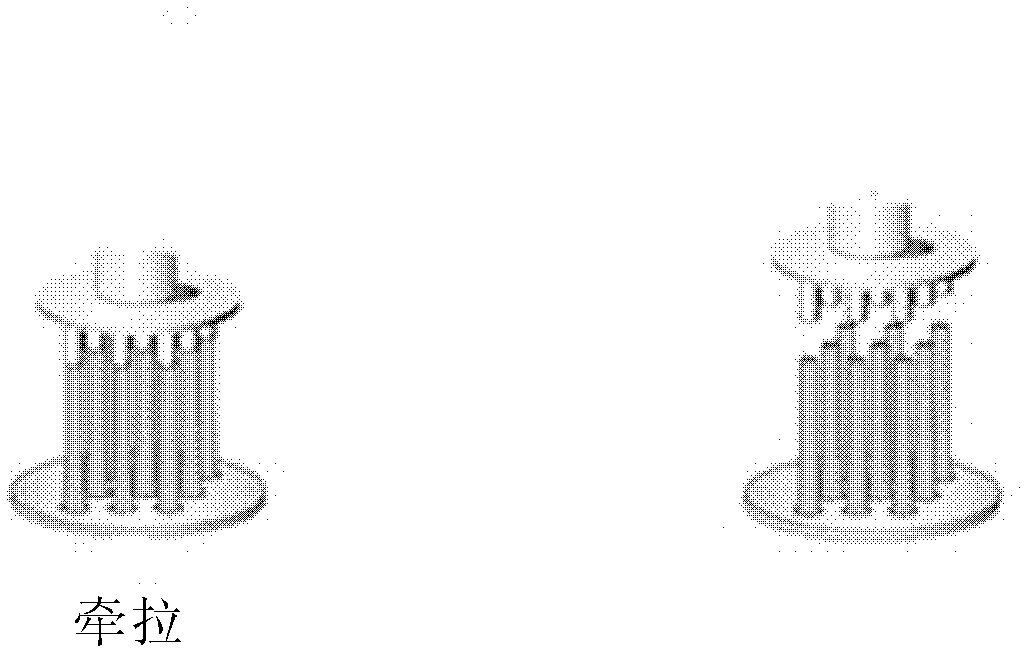

[0084] (2) Put the prepared stainless steel column frame (such as figure 1 shown) adhered to the spread maltose, and microneedles with different needle shapes could be prepared according to pulling the maltose at different temperatures.

[0085] (3) a. Baseball rod-shaped microneedles: Control the temperature at 100°C, when the maltose matrix is in a glass state, pull the maltose at a speed of 400μm / s for 3s, cool down to 60°C, cool and solidify the microneedles, ...

Embodiment 2

[0088] Example 2 Preparation of triamcinolone acetonide biodegradable maltose microneedle array by micromolding method

[0089] (1) Dissolve 10 mg maltose and 10 μL deionized at 110° C. for 10 min, then add 1 mg powdered triamcinolone acetonide and mix well.

[0090] (2) Pour the liquid mixture into a conical mold, cover with a 300g stainless steel plate, and cool slowly to make it solidify. The steel plate is then removed, separating the solid microneedles from the mold.

Embodiment 3

[0091] Example 3 Pain Sensation Experiment of Triamcinolone Maltose Microneedle Array

[0092] (1) Case source: 12 scar patients, aged 22-53 years, with an average age of (37.59±8.04) years, including 6 males and 6 females.

[0093] (2) Administration method: local injection of triamcinolone acetonide injection and triamcinolone acetonide maltose microneedle array administration respectively.

[0094] (3) The patient's pain score standard is shown in Table 1:

[0095] Table 1

[0096] It's a sharp pain

more painful

pain

a little pain

painless

10-8

8-6

6-4

4-2

2-0

[0097] (4) Statistical method

[0098] The data are represented by mean ± standard deviation (x ± SD), and the statistical analysis is carried out with SAS6.12 statistical analysis software, and the data of different administration methods are analyzed by paired t test, and P<0.01 means that the difference is statistically significant.

[0099] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com