Preparation method of cordate houttuynia oil

A manufacturing method, Houttuynia cordata technology, applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, plant raw materials, etc., can solve the problem of low purity of Houttuynia cordata oil, low bioavailability, pollution of Houttuynia cordata oil, etc. problems, to achieve the effect of fine crushing, high bioavailability, energy saving and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

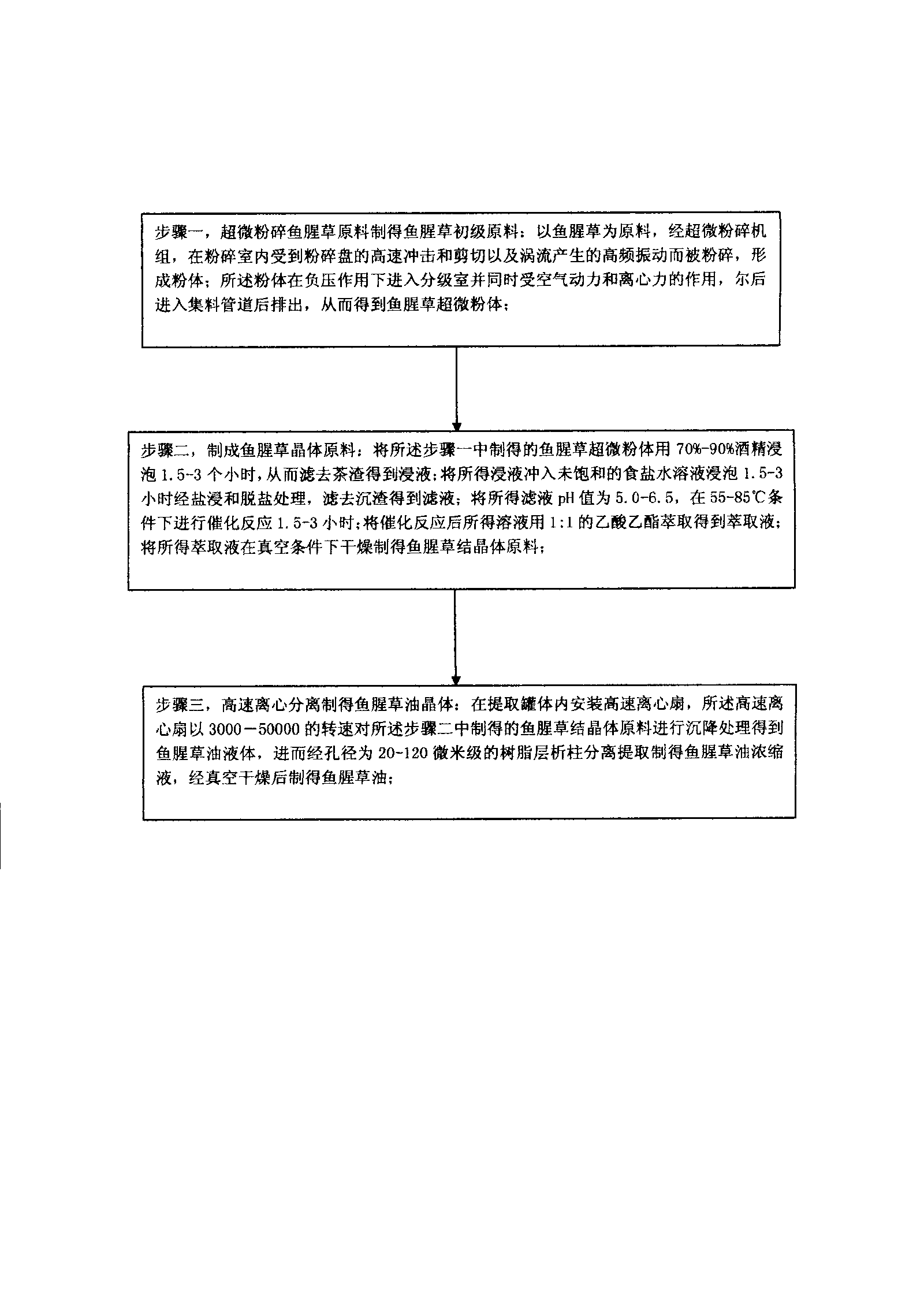

[0016] The present invention will be further described below in combination with principle diagrams and specific operation examples.

[0017] Such as figure 1 Shown, the manufacture method of a kind of Houttuynia cordata oil of the present invention, at first, with Houttuynia cordata as raw material, adopts LF type superfine pulverizer unit to carry out superfine pulverization, when Houttuynia cordata particle is sent into pulverization chamber by feeding port screw, It is crushed by the high-speed impact and shear of the crushing disc, and also by the high-frequency vibration generated by the eddy current. The pulverized powder enters the classification chamber through the diverter cone sleeve under the action of negative pressure. Due to the high-speed rotation of the classifying wheel, the powder is simultaneously affected by aerodynamic force and centrifugal force. When the centrifugal force>aerodynamic force, it means that the powder is larger than the pre-set grading p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com