Xinkeshu capsule preparation method

A technology of Xinkeshu capsules and capsules, which is applied in capsule delivery, medical preparations containing active ingredients, pharmaceutical formulas, etc. It can solve problems such as the inability to show the great advantages of modern preparation methods, avoid bacterial contamination and improve internal quality , The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of Xinkeshu capsule comprises the following process steps:

[0054] a. Prepare materials

[0055] Sorting, cleaning, cutting and drying of salvia miltiorrhiza, hawthorn, woody fragrance, kudzu root and notoginseng respectively;

[0056] b. Superfine pulverization of Panax notoginseng and woody fragrance

[0057] The notoginseng and woody fragrance treated in step a are made into fine powder of notoginseng and woody fragrance through ultrafine pulverization;

[0058] c. Preparation of mixed thick paste

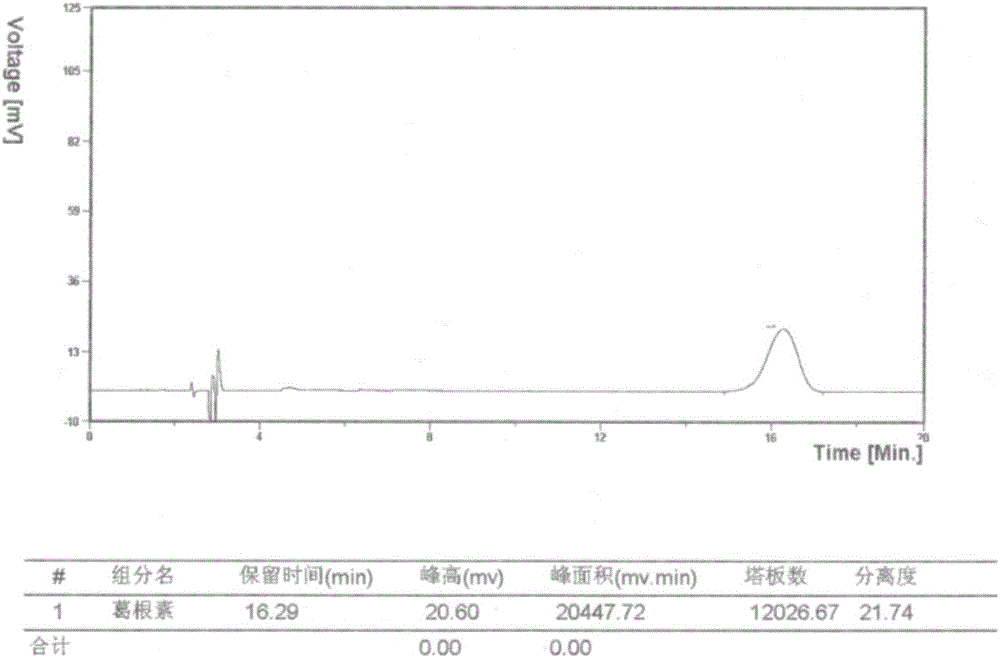

[0059] After warming the hawthorn and kudzu root treated in step a with ethanol, heat and reflux for extraction, high-speed centrifugation and filtration of the alcohol extract, recovery of ethanol under reduced pressure, concentration to prepare a mixed thick paste with a relative density of 1.35 at a temperature of 20°C;

[0060] d, the preparation of Danshen thick paste

[0061] decocting the Danshen treated in step a with water, centrifugal...

Embodiment 2

[0071] The difference between this embodiment and embodiment 1 is:

[0072] In the step c, the speed of the high-speed centrifugation is 15,000 rpm, and the time is 15 minutes; the process conditions for recovering ethanol under reduced pressure are a temperature of 55° C., a pressure of 0.10 MPa, and a time of 6 hours.

[0073] In the step d, the speed of high-speed centrifugation is 13000 rpm, and the time is 10 minutes. The process conditions for concentration under reduced pressure are that the temperature is 80° C., the pressure is 0.07 MPa, and the time is 6 hours.

[0074] The vacuum drying in the step e adopts a vacuum belt dryer, and the process conditions of the vacuum drying are: pressure 0.005 MPa, temperature 50° C., time 40 minutes, feed rate 60 kg / h, crawler speed 8 cm / min .

[0075] All the other contents are the same as in Example 1.

Embodiment 3

[0077] The difference between this embodiment and embodiment 1 is:

[0078] In the step c, the speed of high-speed centrifugation is 13,500 rpm, and the time is 18 minutes; the process conditions for recovering ethanol under reduced pressure are temperature 53° C., pressure 0.07 MPa, and time 8 hours.

[0079] In the step d, the speed of high-speed centrifugation is 12000 rpm, and the time is 15 minutes. The technological conditions for concentration under reduced pressure are that the temperature is 70° C., the pressure is 0.06 MPa, and the time is 9 hours.

[0080] The vacuum drying in the step e adopts a vacuum belt dryer, and the process conditions of the vacuum drying are: pressure 0.003 MPa, temperature 48° C., time 50 minutes, feed rate 55 kg / h, crawler speed 6 cm / min .

[0081] All the other contents are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com