Glue regulating powder feeding device convenient to use

A feeding device and powder technology, which is applied in the field of modulation glue feeding device, can solve the problems of increased volatile solvent concentration of glue, increased solvent volatilization, and prone to dust explosion, so as to improve feeding efficiency and safety, and increase dispersion resistance, avoid caking or accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

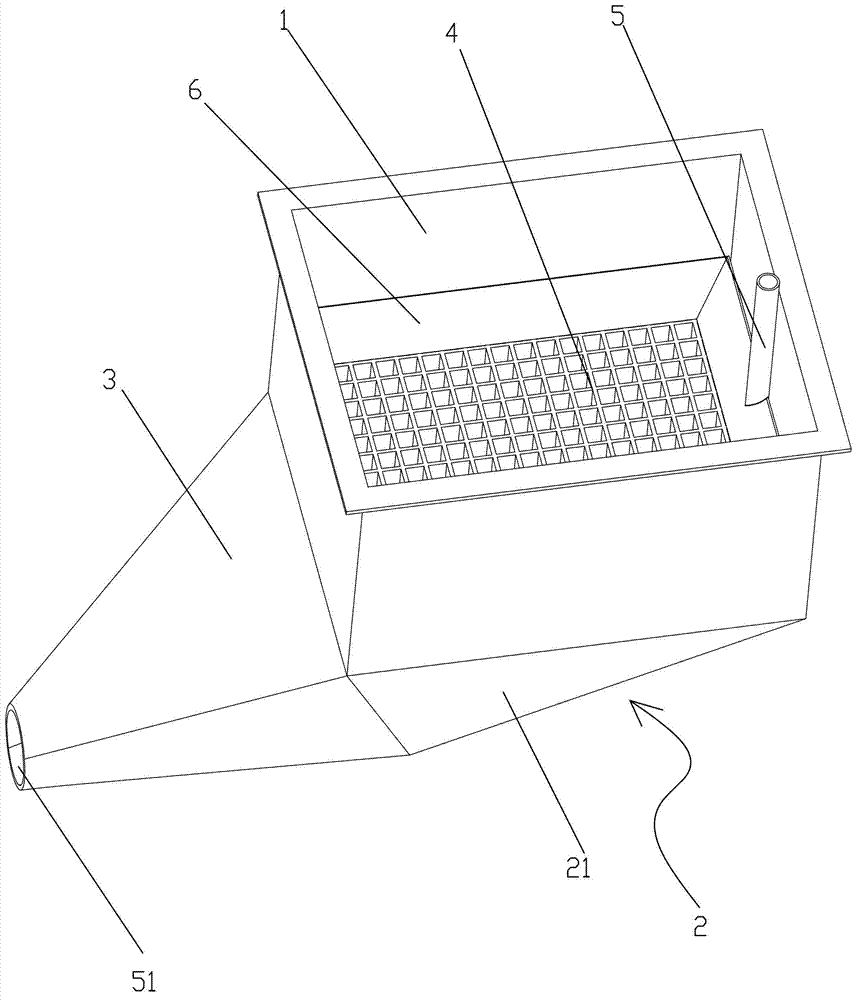

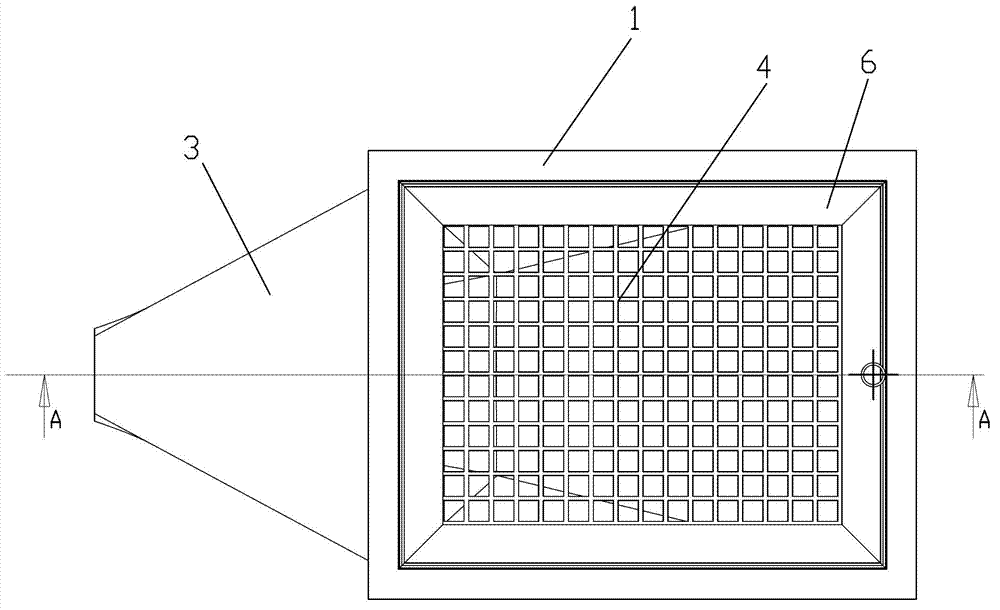

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

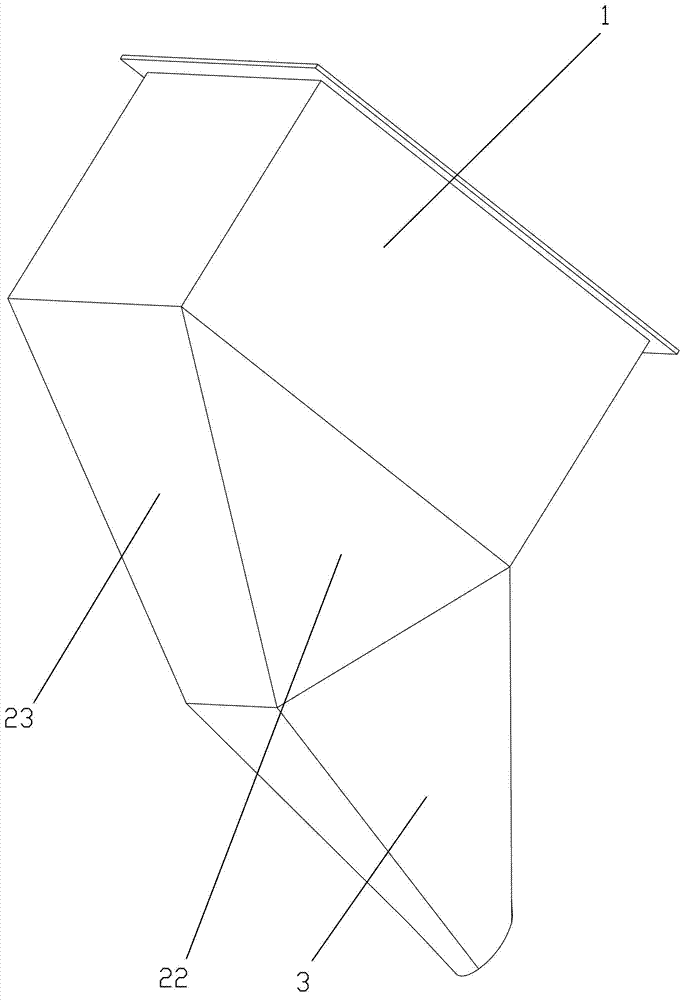

[0022] As shown in the figure, an easy-to-use rubber mixing powder feeding device includes a tank body 1 communicating up and down, and a drop hopper 2 communicating with the bottom of the tank body 1 is provided at the bottom of the tank body 1. One side of the falling hopper 2 is provided with a discharge nozzle 3, the tank body 1 is provided with a feeding screen 4 made of conductive material, and the bottom of the feeding screen 4 is provided with a solvent pouring pipe 5, so The above solvent pouring pipe 5 is provided with a solvent outlet 51. The solvent pouring pipe 5 communicates with the glue mixing tank, and the solvent in the pipe and the solution in the glue mixing tank form a flow cycle to achieve sufficient mixing.

[0023] The falling hopper 2 includes a left side plate 21 and a right side plate 22 which are in contact with the bottom of the tank body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com