Automatic water cooling system of car brake

A water-cooling system and automobile brake technology, applied in the direction of brakes, vehicle parts, cooling brakes, etc., can solve the problem of unreasonable installation of temperature sensors, and achieve the effect of easy maintenance, accurate water spray control, and stable installation position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing, in order to help understanding content of the present invention.

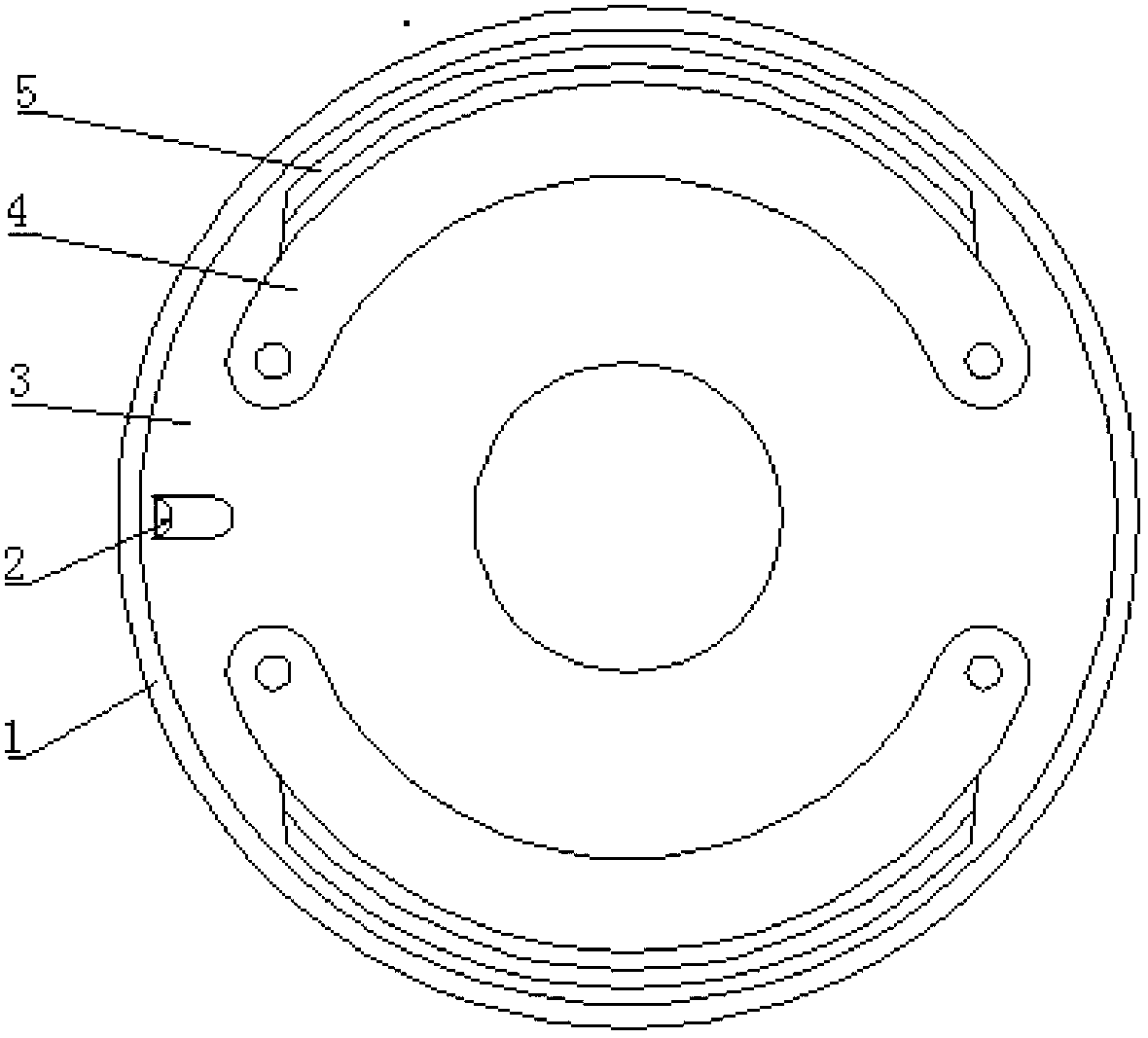

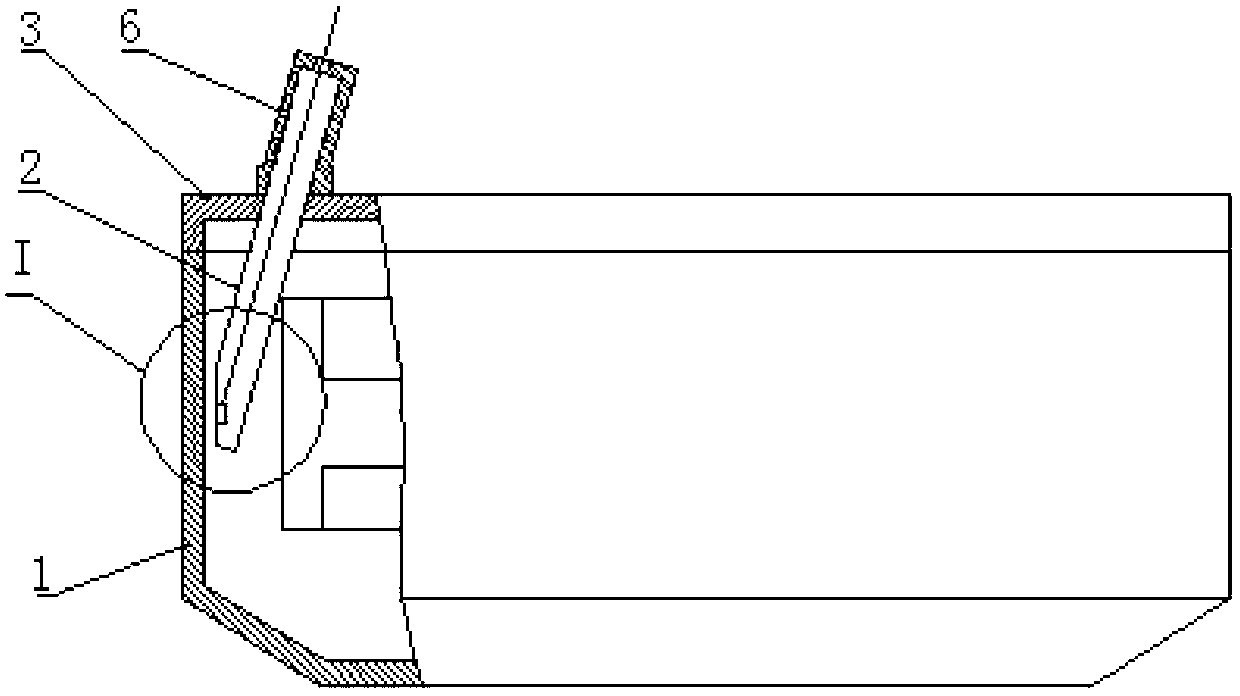

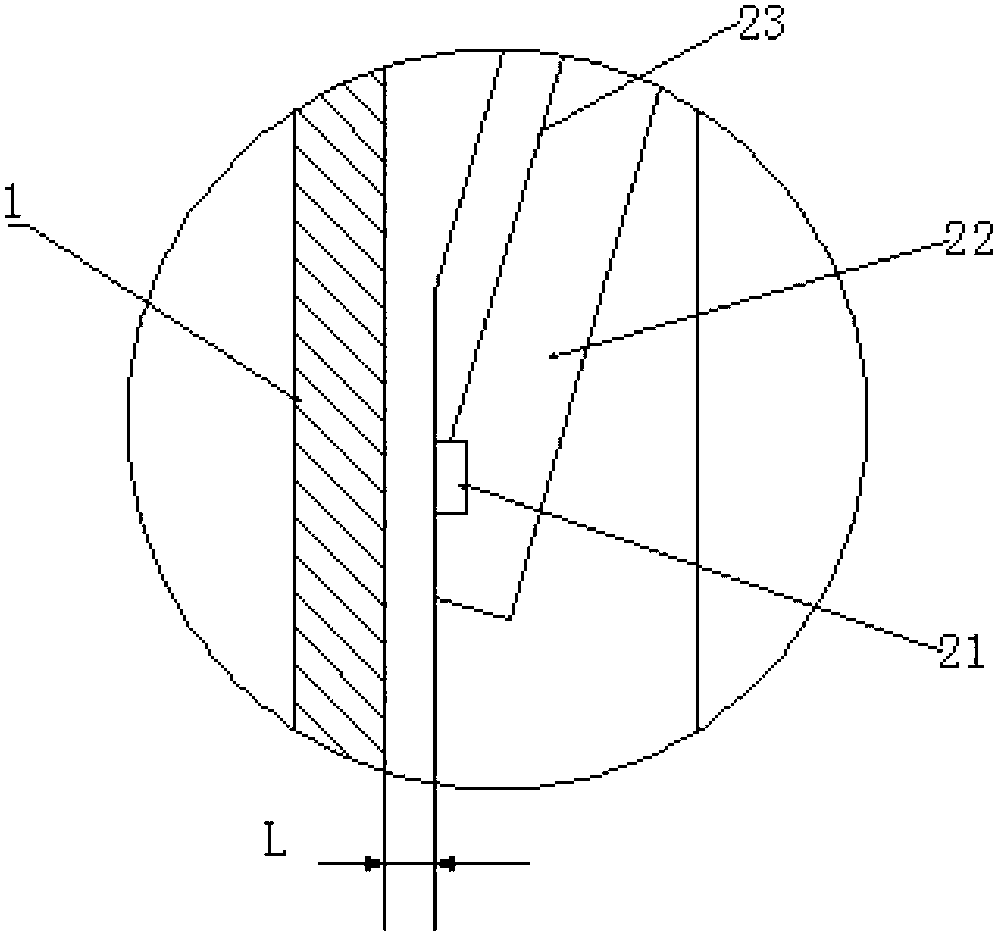

[0025] Such as Figure 6 As shown, the automatic water cooling system for automobile brakes that the present invention relates to includes a water tank 14, a controller 11, a temperature sensor 2, a control valve 13, a booster water pump 10 and a shower nozzle 8, and the water tank 14 is installed on the vehicle frame of the automobile. A booster water pump 10 is installed on the water outlet main pipe to provide water pressure, and the water outlet of the water pump 10 is connected to the water distribution pipe leading to the brake drum 1 of each brake. Each water distribution pipe is equipped with a control valve 13 and a shower nozzle 8 , each temperature sensor is connected to the input end of the controller 11 through wires (dotted line in the figure), and the output end of the controller 11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com