Belt guiding device for belt conveyor

A belt conveyor and belt technology, which is applied in the field of belt installation in pipelines, can solve the problems that the belt consumes a lot of manpower, material and financial resources, the belt is prone to scraping the frame, and the belt is torn, so as to save manpower investment and debugging time, and ensure safety. Efficient installation and debugging, the effect of preventing broken belt joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

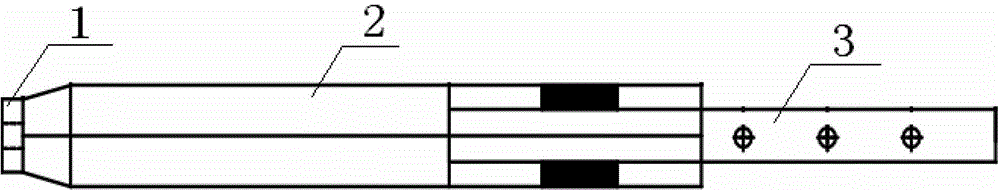

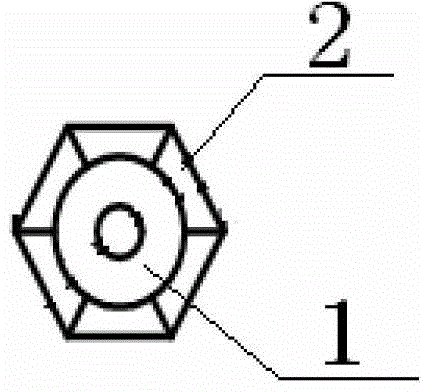

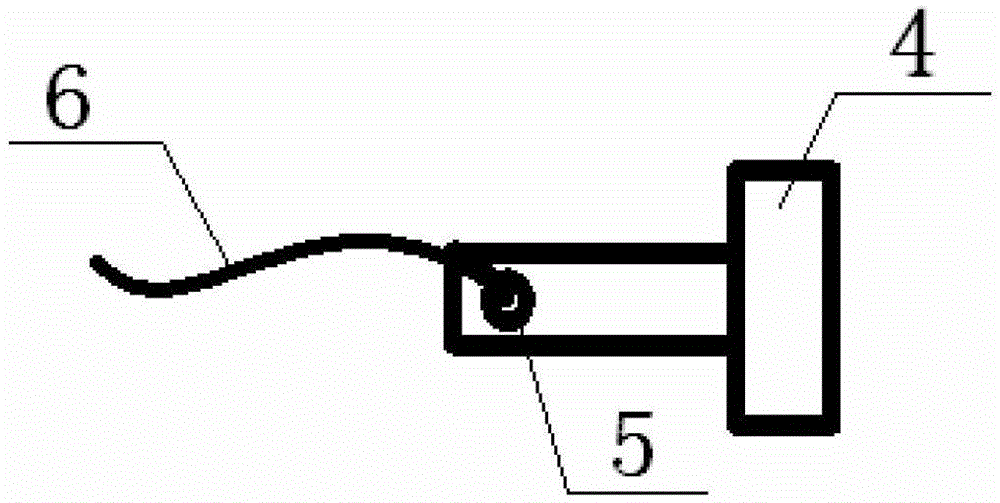

[0018] figure 1 It is a structural schematic diagram of the leader shaft of the present invention; figure 2 for figure 1 left view of image 3 It is a structural schematic diagram of the pin shaft of the present invention.

[0019] The invention discloses a belt conveyor belt device, such as Figure 1-3 As shown, it includes the pin shaft and the belt shaft. The leader shaft includes the pin shaft connecting section 1, the passing section 2 and the belt fixing section 3 connected in sequence. The pin connecting section 1 is 0.16m long, and the passing section 2 is long. 1.5m, the belt fixed section 3 is long 0.7m. According to different roadways, the lengths of the pin shaft connection section 1, the threading section 2 and the belt fixing section 3 are adjustable. In this embodiment, the pin connection section 1, the threading section 2 and the belt fixing section 3 are integrally formed. The pin shaft and leader shaft can be made of any metal material. In this embodim...

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, except that in this embodiment, the length of the connecting section of the pin shaft is 0.2m, the length of the threading section is 1.8m, and the length of the belt fixing section is 0.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com