Roof rainwater recovery treatment process

A technology for recovery and treatment of rainwater, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of unsuitable roof rainwater and improve the utilization rate of rainwater , Low construction and operation costs, good water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

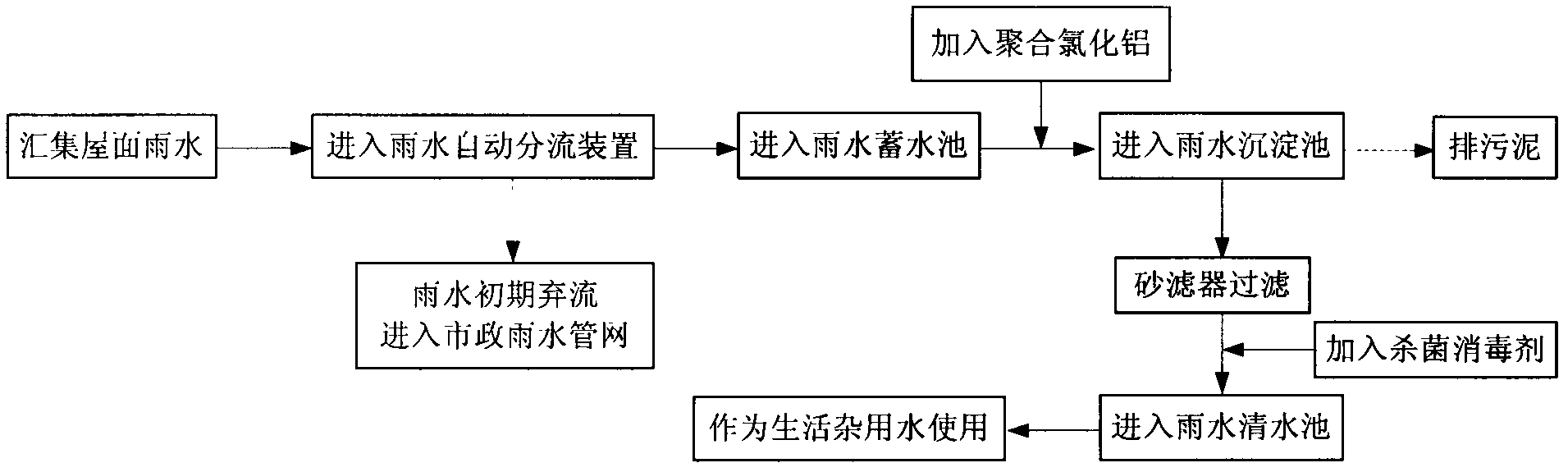

[0036] A trial production test was carried out on the roof rainwater generated in a residential area (see figure 1 ).

[0037] (1) The rainwater on the roof is collected through the siphon downpipe, and then enters the rainwater storage tank after the initial waste flow through the rainwater automatic diversion device. The initial waste flow of rainwater is 3mm runoff thickness, and the rainwater index after the initial waste flow is: COD is 140~180mg / L, BOD is 30-40mg / L, SS is 80-100mg / L, chroma is 100 times;

[0038] (2) The rainwater is lifted into the rainwater sedimentation tank through the lifting pump, and the first dosing device is installed on the outlet pipe of the lifting pump, and polyaluminum chloride is added, and the dosage is 6mg / L, and the coagulation reaction is carried out (reaction time is 40min) while carrying out precipitation treatment (time is 2h);

[0039] (3) Filter with a sand filter (filter speed is 10m 3 / m 2h, the working cycle is 12h), and t...

Embodiment 2

[0043] The trial production test was carried out on the roof rainwater generated by a residential area ( figure 1 ).

[0044] (1) The rainwater on the roof is collected through the siphon downpipe, and then enters the rainwater storage tank after the initial waste flow through the rainwater automatic diversion device. The initial waste flow of rainwater is 2mm runoff thickness; the index of rainwater after the initial waste flow is: COD is 100~ 140mg / L, BOD 25~35mg / L, SS 60~80mg / L, chroma about 90 times;

[0045] (2) The rainwater is lifted into the rainwater sedimentation tank through the lifting pump, and the first dosing device is installed on the outlet pipe of the lifting pump, and polyaluminum chloride is added, and the dosage is 5mg / L, and the coagulation reaction is carried out (the reaction time is 30min) while carrying out precipitation treatment (time is 1.5h);

[0046] (3) Filter with a sand filter (filter speed is 8m 3 / m 2 h, the working cycle is 10h), and th...

Embodiment 3

[0050] A trial production test has been carried out on the roof rainwater produced in a community (see attached figure 1 ).

[0051] (1) Roof rainwater is collected through the siphon downpipe, and then enters the rainwater storage tank after the initial waste flow through the rainwater automatic diversion device. The initial waste flow of rainwater is 2mm runoff thickness; the index of rainwater after the initial waste flow is: COD is 80~ 100mg / L, BOD 15-25mg / L, SS 40-60mg / L, chroma about 80 times.

[0052] (2) The rainwater is lifted into the rainwater sedimentation tank through the lifting pump, and the first dosing device is installed on the outlet pipe of the lifting pump, and polyaluminum chloride is added, and the dosage is 5mg / L, and the coagulation reaction is carried out (the reaction time is 40min) while carrying out precipitation treatment (time is 1.5h);

[0053] (3) Filter with a sand filter (filter speed is 6m 3 / m 2 h, the working cycle is 8h), and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com