A slag stopper for steelmaking converter tapping slag stopper

A technology for steelmaking converters and slag stoppers, which is applied in the manufacture of converters, etc., can solve the problems of slag stopper drift, guide rods not centered, and molten steel phosphorus return exceeding the standard, so as to avoid slag stopper failure and avoid plugging errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

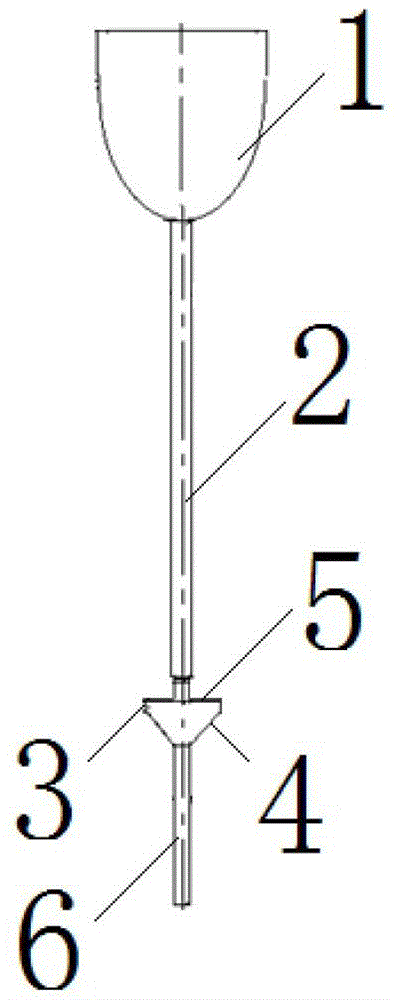

[0014] Such as figure 1 As shown, a slag stopper for steelmaking converter tapping slag stopper includes a slag stopper body 1 , a guide rod 2 and a booster fin block 3 . Preferably, the body 1 of the slag stopper is a half rugby ball structure, one end of the guide rod 2 is connected to the tip of the half rugby ball structure, and the axis of the guide rod 2 is perpendicular to the longitudinal section of the half rugby ball structure.

[0015] The booster fin block 3 is arranged on the other end of the guide rod 2 to provide a boost force for the slag stopper body to enter the taphole of the converter, so that the slag stopper body can quickly and accurately reach the taphole position of the converter.

[0016] The booster fin block 3 is a cone structure, the end face 5 of the cone structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com