Equal altitude test apparatus of air floatation blocks

A testing device and air-floating block technology, which are applied to measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems that affect the rigidity of the I-shaped motion module, the uneven thickness of the air film, and affect the motion performance of the workpiece table.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

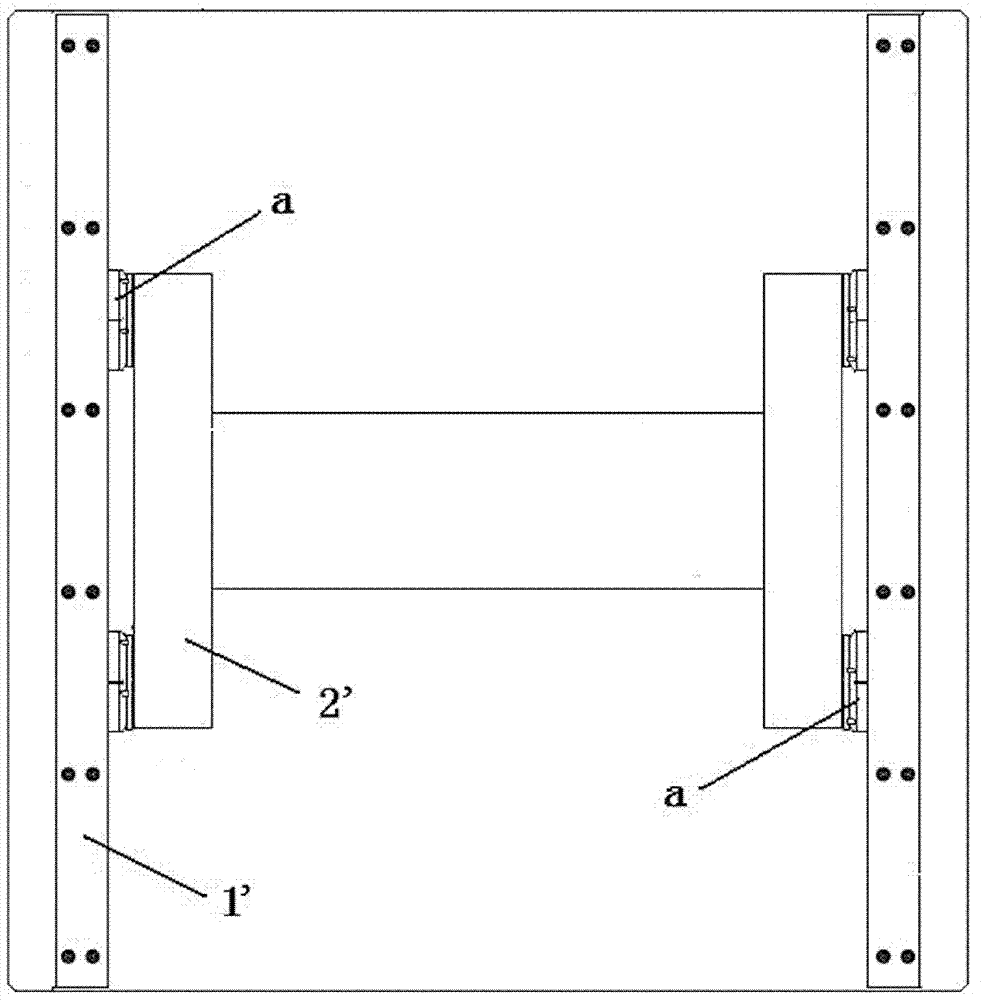

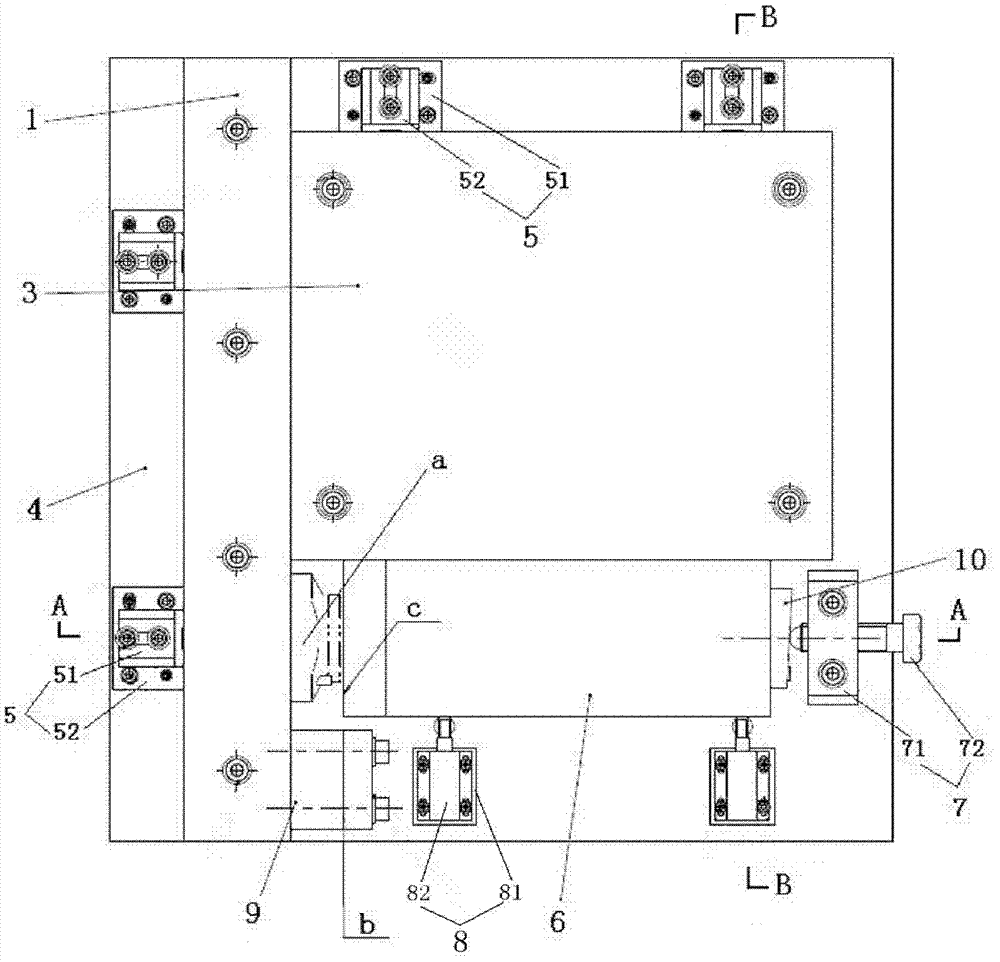

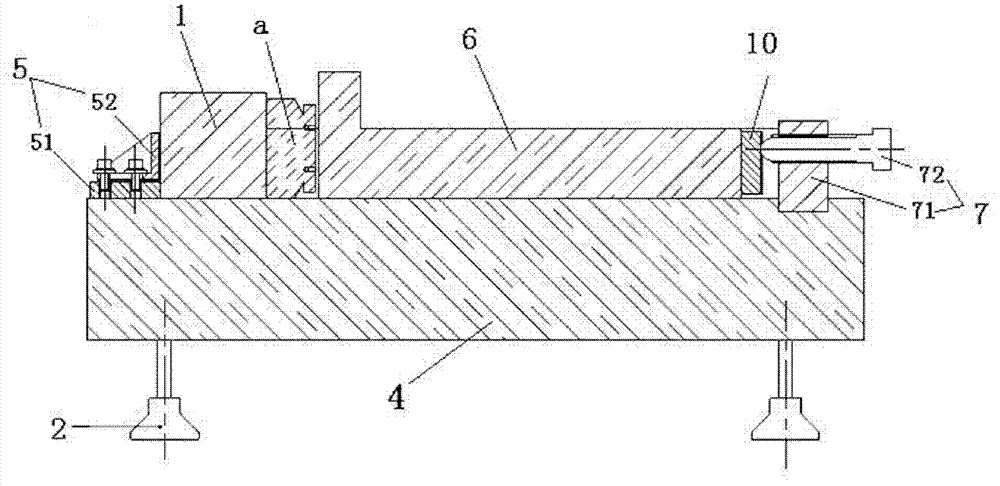

[0040] like figure 2 , image 3 and Figure 4 As shown, the air-floating block contour test device of this embodiment includes a horizontally arranged platform 4, and four feet 2 with adjustable height are installed under the platform 4, so the platform can be adjusted by changing the height of the feet 2 4 level.

[0041] A longitudinally arranged parallel gauge 1 is installed on the platform 4 through hexagon socket screws, and a high-precision measurement reference block 9 mounted on the platform 4 is also arranged on the side of the parallel gauge 1 .

[0042] The platform 4 is also equipped with a horizontally arranged square 3, and the square 3 is located on the right side of the parallel gauge 1 (the so-called "front, rear, left, right" in this example, so figure 2 For reference, the lower part of the paper is "front", and the upper part of the paper is "rear") and is closely attached to the parallel ruler 1, and the square ruler 3 and the parallel ruler 1 are perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com