Three-position four-way electromagnetic ball type reversing valve

A three-position, four-way, reversing valve technology, which is applied to servo motor components, mechanical equipment, fluid pressure actuators, etc., can solve the problems of electromagnetic reversing valve blocking, jamming, drifting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

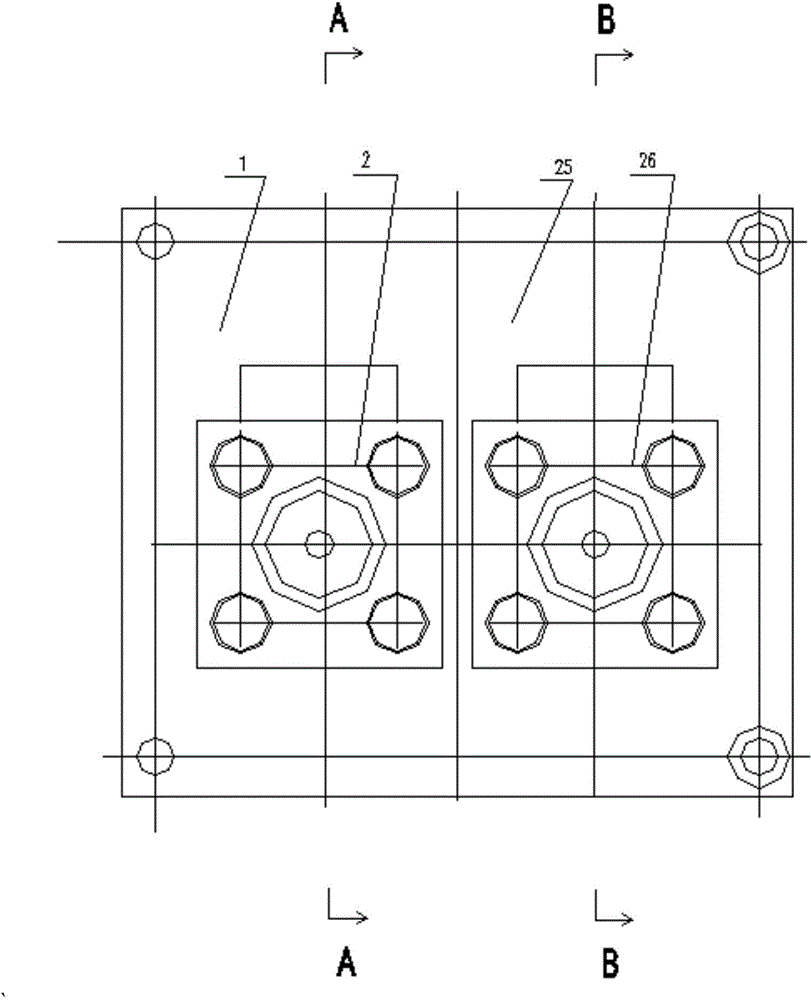

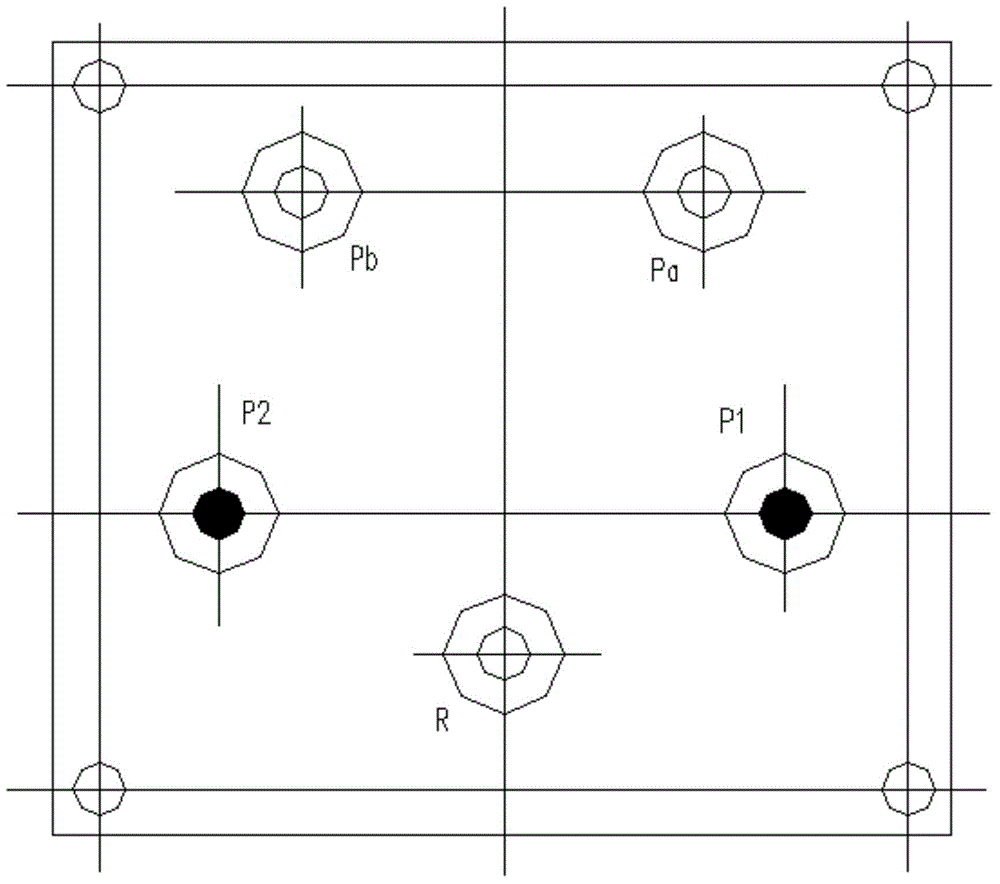

[0032] figure 1 It is the front view of the structure of the three-position four-way electromagnetic logic ball reversing valve of the present invention, which is composed of two sets of valve bodies with the same internal structure, 1 represents valve body A, and 25 represents valve body B. Each group of valve bodies includes pilot stage and power amplifier stage respectively, and the parts include bracket, piston, valve sleeve, screw, O-ring, steel ball, spring, cock, valve seat, electromagnet, ejector rod, upper cover and manual button .

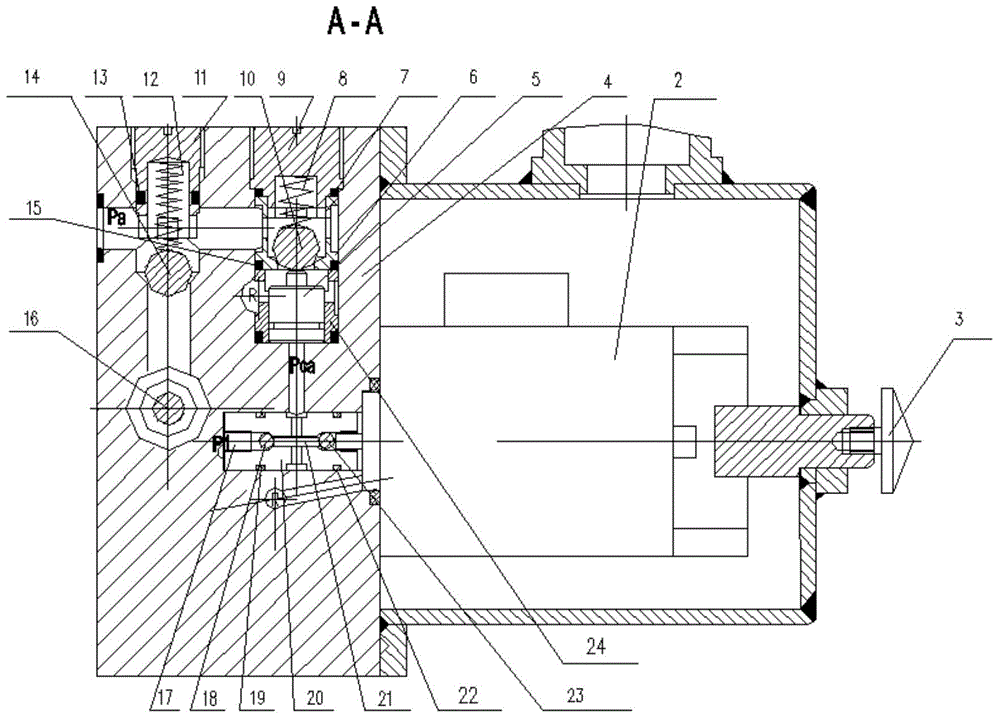

[0033] Such as image 3 As shown, the valve body A includes one hydraulic pilot stage and two hydraulic power amplifier stages, 2 represents the electromagnet A, 3 represents the manual button A, 4 represents the shell A of the valve body A, 5 represents the piston A1, and 6 represents the Seat A1, 7 represents O-ring A3, 8 represents spring A1, 9 represents cock A2, 10 represents steel ball A3, 11 represents cock A3, 12 represents spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com