A process and equipment for producing organic compound fertilizer with straw papermaking chain

A compound fertilizer and straw technology, applied in the fields of organic fertilizers, textiles and papermaking, and application, can solve the problems of reducing the effect of removing impurities, low content of organic matter, and being unable to be used, so as to improve the effect of removing impurities and increase soil organic matter. , the effect of reducing wood consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

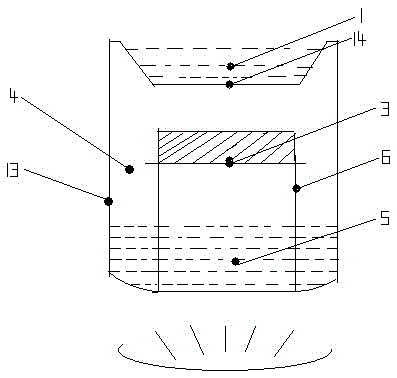

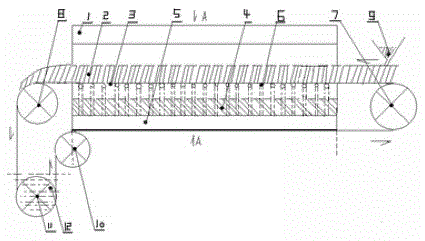

Image

Examples

Embodiment 1

[0043] Prepare JH0 3 and JH0 2 :

[0044] That is, according to the volume ratio of 1:1, dilute 30% hydrogen peroxide with alcohol and mix evenly; prepare 20% sodium hydroxide solution with 50% alcohol aqueous solution as solvent, and cool to room temperature; according to the volume ratio of 1:1, Slowly mix the above two solutions, cool down and separate the phases, take out the upper phase to recover the alcohol, and reuse it, the lower phase is JH0 3 . (also can prepare the sodium peroxide mixed solution JH that contains ozonated sodium according to the method that Chinese invention patent disclosure specification CN1360848A provides 3 ):

[0045] Sodium peroxide alkaline solution (JH0 2 ) Preparation: Prepare 15-40% sodium hydroxide solution with tap water, cool to room temperature, slowly add 30% hydrogen peroxide solution into it according to the volume ratio of 1:1, and obtain JH0 2 .

[0046] Straw pretreatment: Weigh two portions of the truncated wheat stra...

Embodiment 2

[0051] Take by weighing three parts of wheat straw cut short material, according to wheat straw material and JH0 3 Different proportions of JH0 were added 3 Mix well, and react under humidity at room temperature for 1 hour. Other experimental conditions are the same as in Example 1, and then steamed under the condition of 5kpa-30min. The neutral slurry is dehydrated and weighed. The results show that with JH0 3 With the increase of the addition amount, the pulp removal effect is improved, the whiteness is increased, and the pulp yield is reduced.

[0052] Wheat straw: JH0 3

Embodiment 3

[0054] Weigh three parts of wheat straw shortening material, according to wheat straw material: JH0 3 =1:0.6 ratio into JH0 respectively 3 Mix well, wet and react at room temperature for 1 hour, make a mixed slurry according to the method of Example 1, and then use steaming and pressing, steaming and cold pressing to remove impurities, remove water and waste water from the pulp, wash and dry it, and weigh it. Heavy. The results show that the leaching pulp is better.

[0055] Impurity removal method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com