Volcanic rock sound-proof noise barrier

A volcanic stone and sound barrier technology, applied in the field of noise reduction and noise reduction, can solve the problems of high cost, unsatisfactory noise reduction effect, pollution of the environment, etc., and achieve the effect of saving metal materials, eliminating light pollution, and eliminating light reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

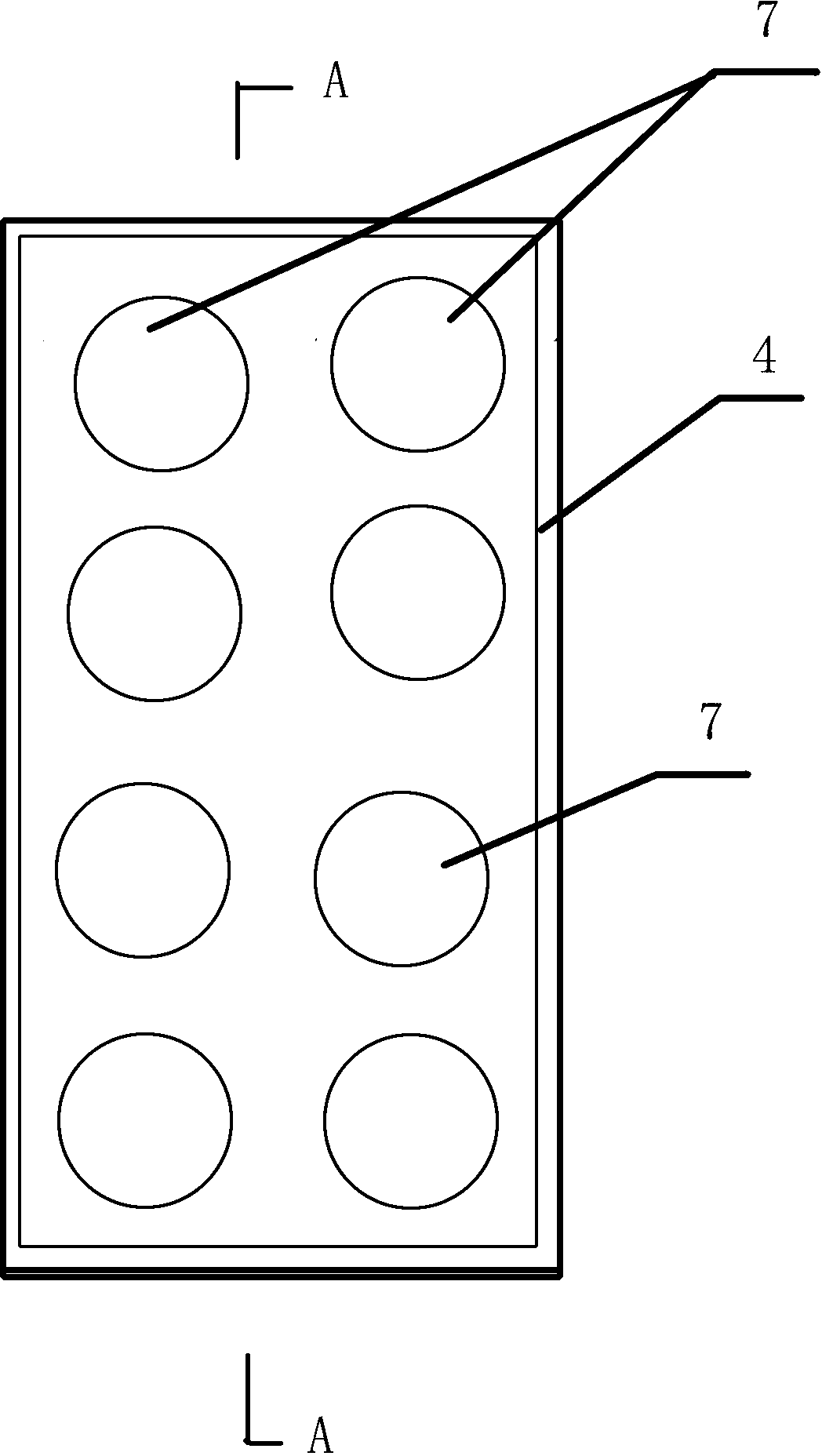

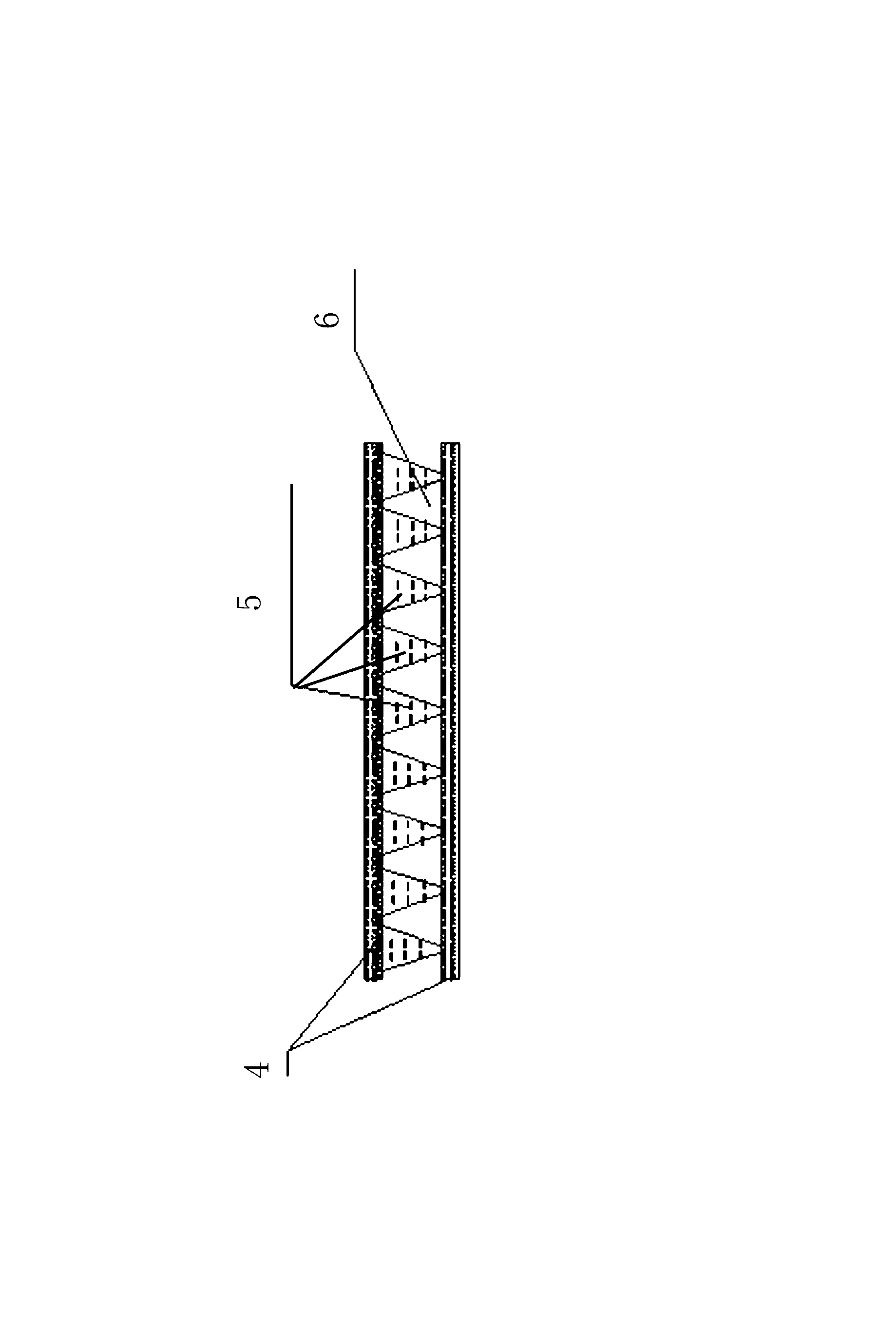

[0033] Example 1: The volcanic stone sound insulation sound barrier / volcanic stone sound insulation sound barrier board for urban rail transit consists of a volcanic stone hollow frame 4 with a certain thickness, a plurality of conical volcanic stones 5 and a volcanic stone hollow frame and a plurality of conical volcanic stones. The cavity 6 formed by volcanic rocks constitutes. The porosity of the volcanic rock is 96%. The pores in the volcanic rock are naturally formed and uneven. The pore diameter can be 0.8 mm to 5 mm, the thickness is 20 mm to 50 mm, and the aspect ratio of the volcanic rock hollow frame 1 is 100: 100-20.

[0034] First select suitable volcanic stones and make a hollow brick-shaped hollow frame with a certain thickness and an aspect ratio of 100:100-20; place and assemble a plurality of conical volcanic stones 5 on the volcanic stone hollow frame 4, conical The bottom of the volcanic stone 5 is tightly stuck on the volcanic stone hollow frame body 4 t...

Embodiment 2

[0037] Example 2: The volcanic stone sound insulation sound barrier / volcanic stone sound insulation sound barrier board for urban highways consists of a volcanic stone hollow frame 4 with a certain thickness, multiple conical volcanic stones 5 and plate-shaped volcanic stone hollow frames 4 and multiple pieces The cavity 6 formed by the conical volcanic rock 5 constitutes. The porosity of the volcanic stone is 66%. The pores on it are naturally formed and uneven. The pore diameter can be 1mm to 10mm, the thickness is 10mm to 30mm, and the aspect ratio of the plate-shaped volcanic stone is 100:100-20.

[0038] First select suitable volcanic stones and make a hollow brick-shaped hollow frame 4 with a certain thickness and an aspect ratio of 100:100-20; place and assemble a plurality of conical volcanic stones 5 on the hollow brick-shaped volcanic stone hollow frame 4 The bottom of the conical volcanic stone 5 is tightly stuck on the upper plate volcanic stone of the volcanic s...

Embodiment 3

[0040] Example 3: The volcanic stone sound insulation sound barrier / volcanic stone sound insulation sound barrier board used in industrial factories is formed by a plate-shaped volcanic stone 4 with a certain thickness, a plurality of conical volcanic stones 5 , and a plate-shaped volcanic stone and a plurality of conical volcanic stones A cavity 6 is formed. The porosity of the volcanic stone is 20%, and the pores on it are naturally formed and uneven. The pore diameter can range from 0.8mm to 5mm, the thickness is 20mm to 50mm, and the aspect ratio of the plate-shaped volcanic stone is 100:100-20.

[0041]First select the appropriate volcanic stone and make it into a hollow brick shape with a certain thickness and an aspect ratio of 100:100~20; assemble multiple conical volcanic stones on the hollow brick-shaped volcanic stone, and the bottom of the conical volcanic stone should be clamped upwards. On the upper plate-shaped volcanic rock, its surface is flush with the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com