Construction method of rapid formwork support for cylindrical hoop-type paired wood formwork

A construction method and wood formwork technology, which is applied in the fields of formwork/formwork/work frame, formwork treatment, and on-site preparation of building components, which can solve the problems of high formwork cleaning and maintenance requirements, rough concrete surface, and customized processing time. Long and other problems, to achieve the effect of flexible assembly, light weight and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Embodiment: The application of this construction method in Deqing Delan Square Project, Hangzheng Chuchu (2007) 16# plot financial and commercial housing project, and animation production base project of Hangzhou Dukou Network Technology Co., Ltd.

[0064] Materials used in this embodiment: hoop-type paired wooden formwork, auxiliary round planks (blocking pads), fixing hoops, M10-M14 ordinary bolts, and mold release agents;

[0065] Construction tools: adjustable wrench, wire pendant, hammer, pliers, steel tape measure, crowbar.

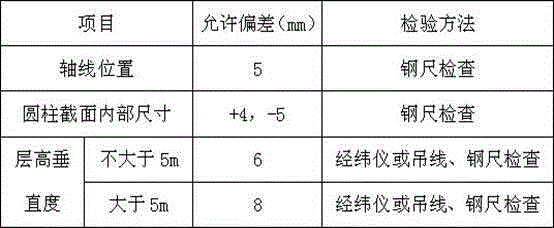

[0066] In this embodiment, the lateral pressure of the concrete should be calculated according to the diameter, height, and pouring speed of the concrete cylinder, so as to determine the thickness of the formwork, the distance between the fixing hoops, and the number of locking bolts.

[0067] The design of the cylindrical hoop-type paired wooden formwork of the present invention includes the strength design of the formwork panel and the desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com