Driving part structure of working vehicle

A technology for working vehicles and parts, which is applied to the layout of vehicle components and power unit cooling combined, power units, etc., can solve the problems of reduced engine cooling efficiency, maintenance of hydraulic continuously variable transmission, and difficulty in inspection operations, etc. The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, although the direction is shown and demonstrated conveniently for easy understanding, the structure is not limited by these.

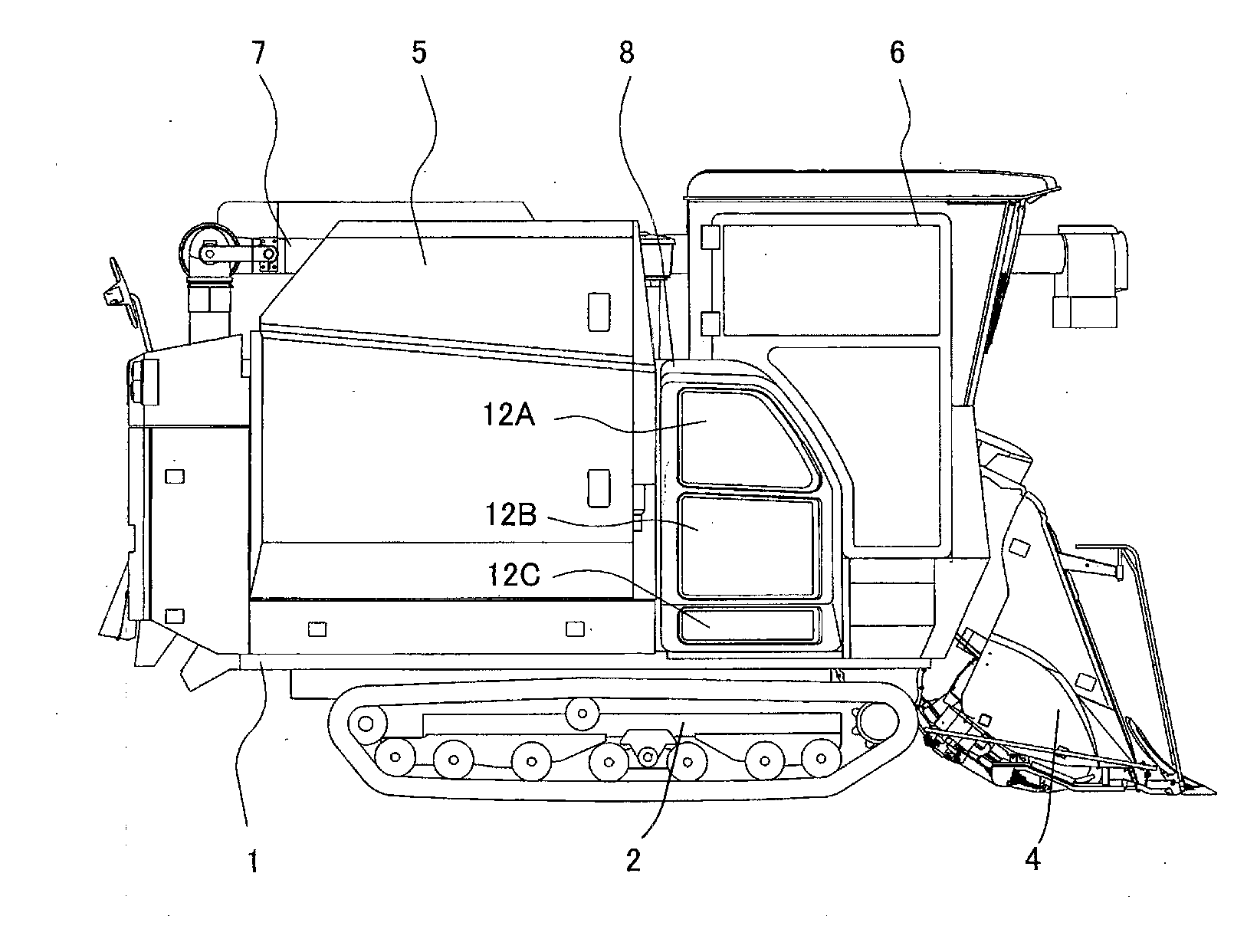

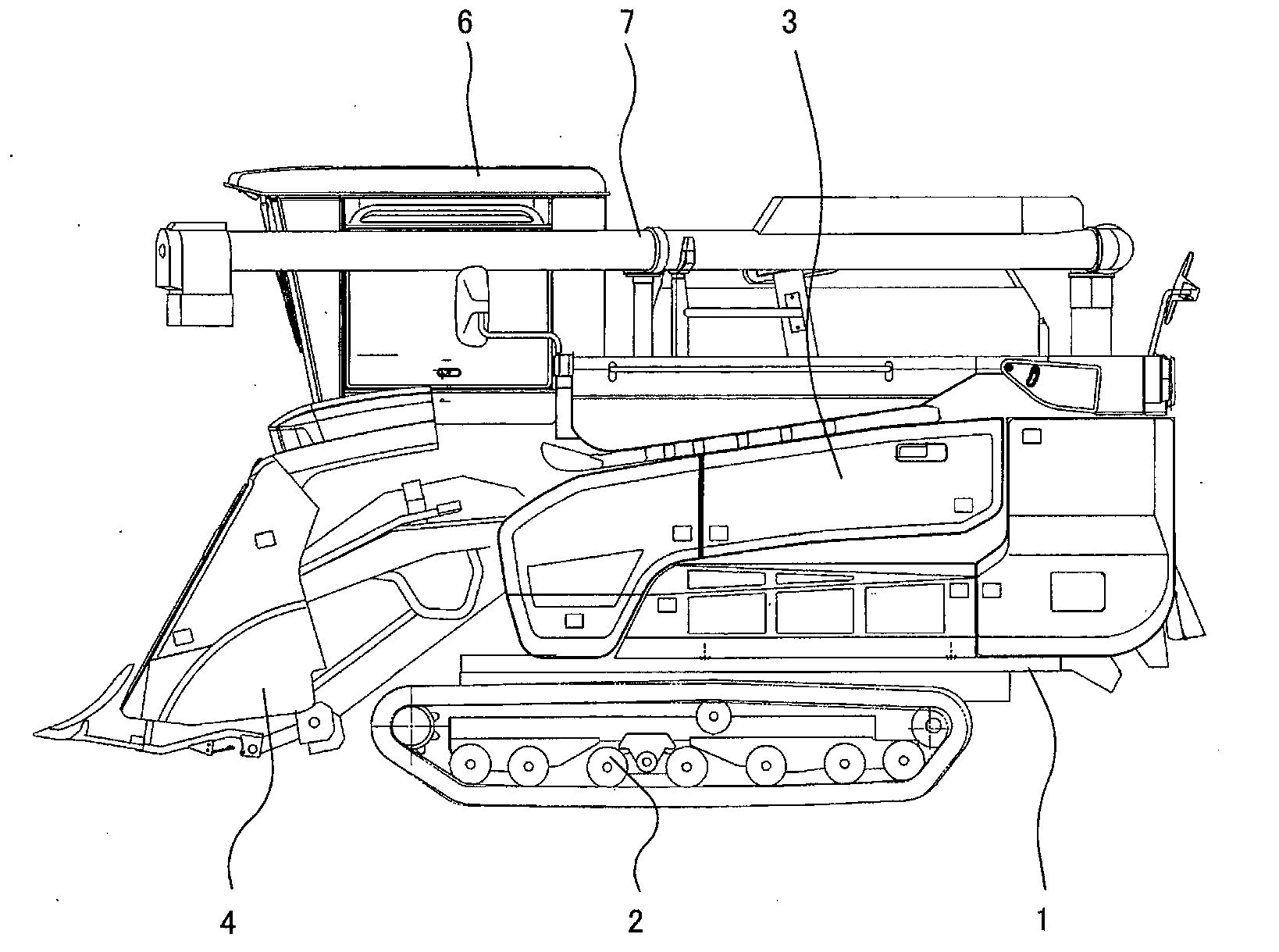

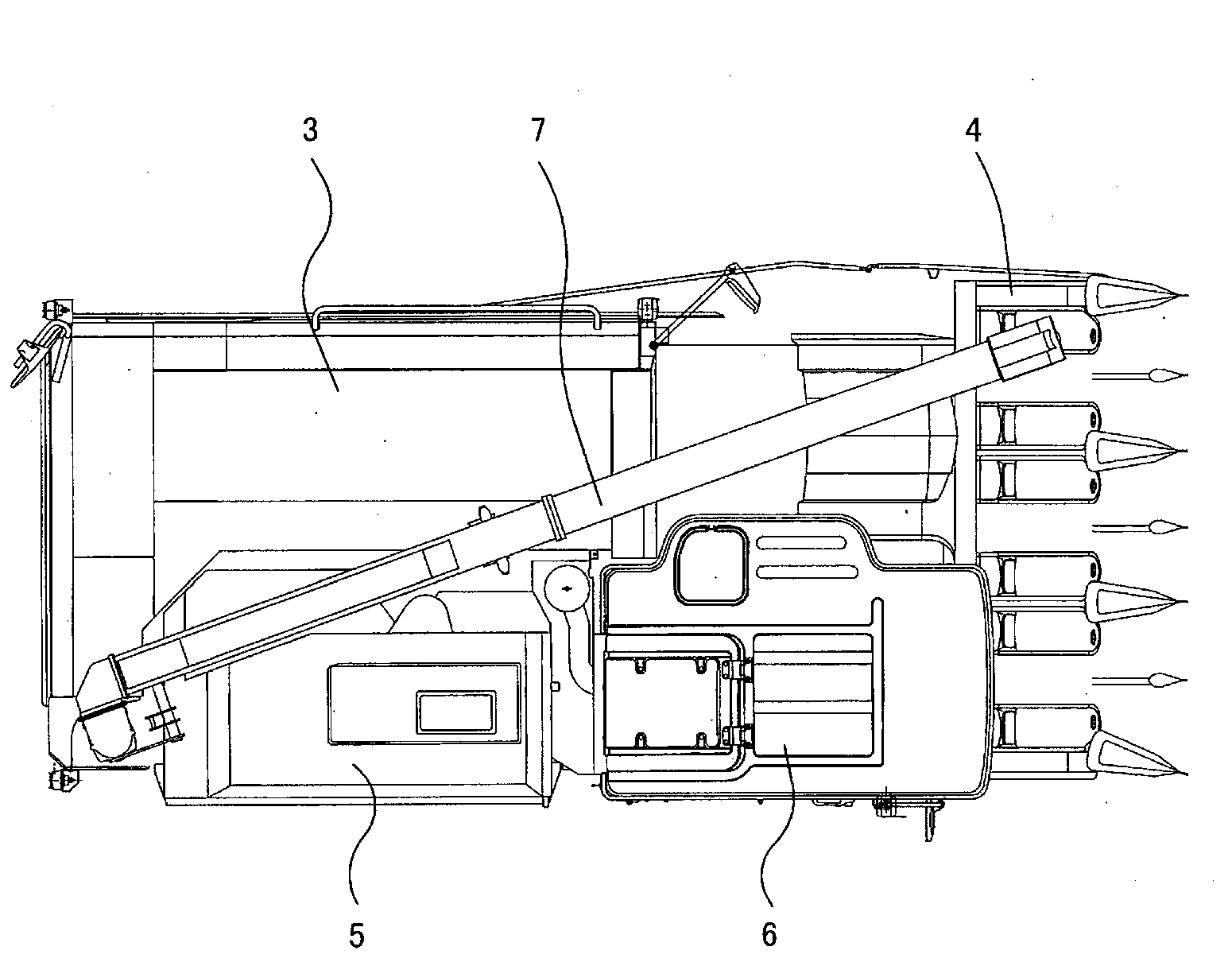

[0064] Such as Figure 1 to Figure 3 As shown, in the combine harvester, a walking device 2 consisting of a pair of left and right crawlers walking on the soil surface is provided below the body frame 1, and a threshing machine for threshing and screening is provided on the upper left side of the body frame 1. The device 3 is provided with a harvesting device 4 for harvesting grain stalks in the field in front of the threshing device 3 . The grains threshed and screened by the threshing device 3 are accumulated in the grain tank 5 provided on the right side of the threshing device 3 , and the stored grains are discharged to the outside by the discharge cylinder 7 . Further, a cab 6 is provided on the upper right side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com