Cold-rolled wire steel reversing device

A technology of wire rod and winch, which is applied in the direction of metal rolling, metal rolling, bending workpieces, etc., can solve the problems of difficult and difficult removal of steel bars, and achieve the effects of saving accident handling time, improving operating rate, and reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained in conjunction with the drawings:

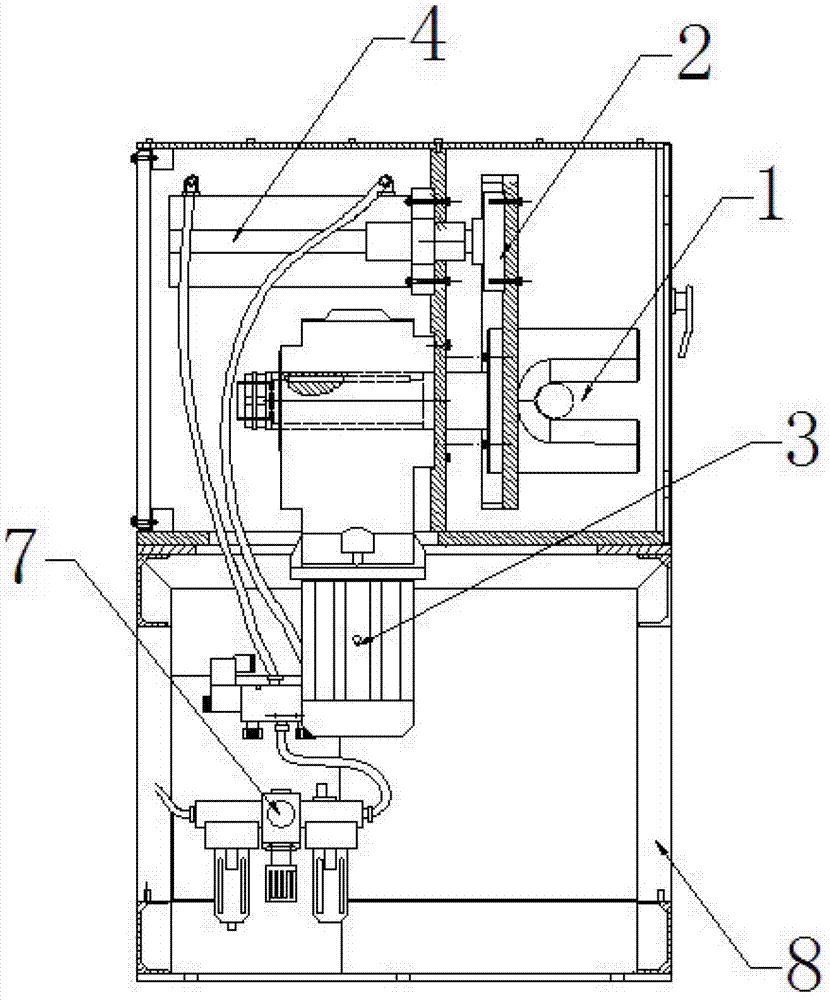

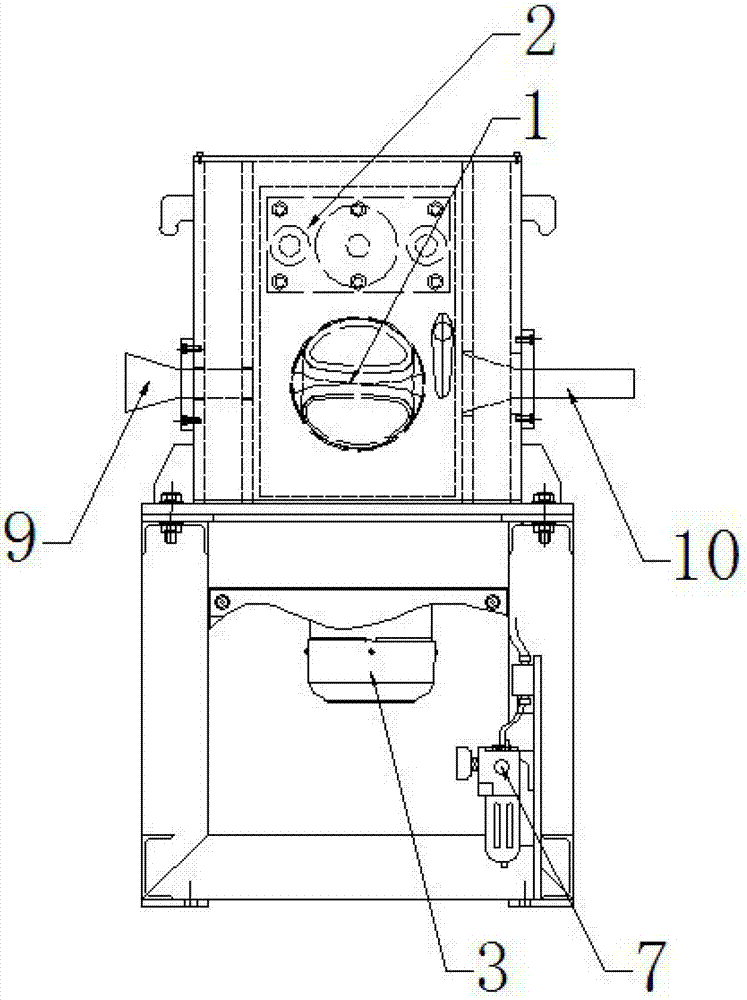

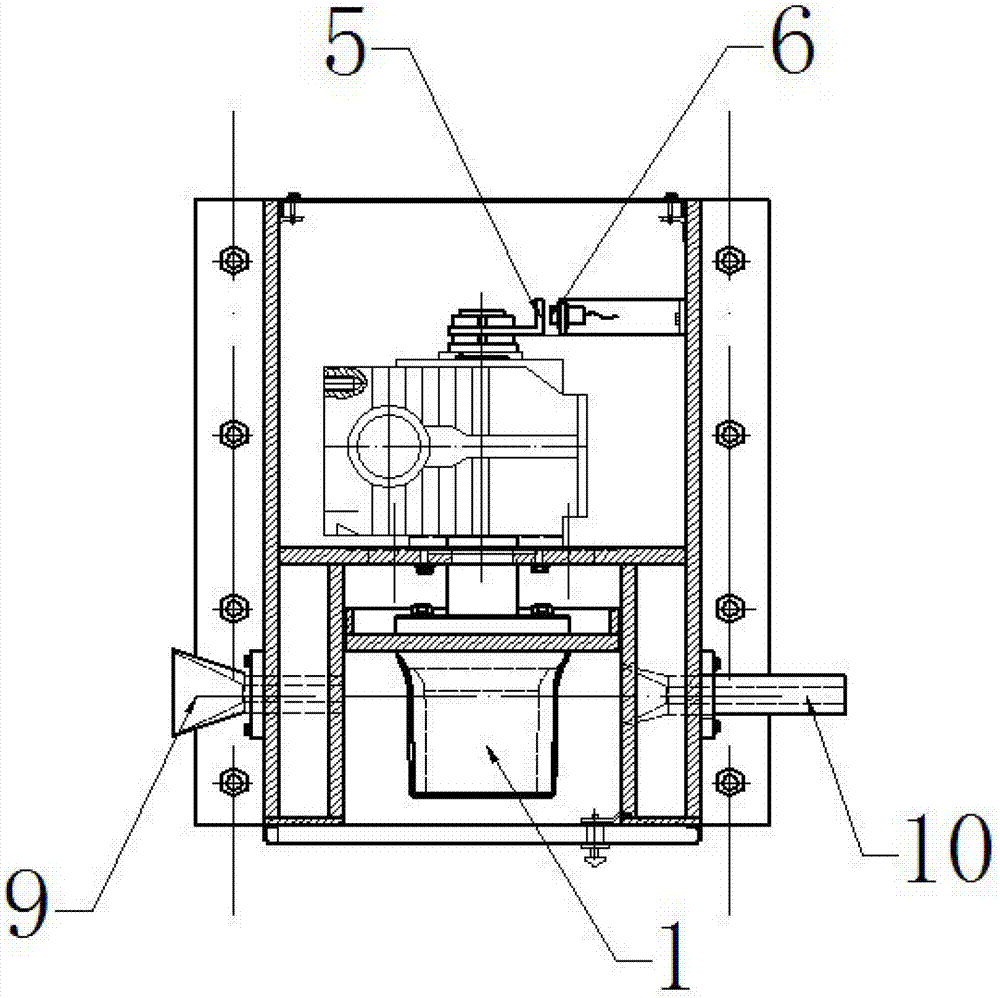

[0018] Such as figure 1 As shown, a cold-rolled wire rod pouring device includes a winch and a push plate 2. The winch is connected to a drive motor 3 through a motor reducer. The winch has a U-shaped groove 1, and the push plate 2 is connected to A guide rod of an air cylinder 4 is connected, and a through groove matching the winch is opened on the push plate 2, and the U-shaped groove 1 of the winch passes through the through groove. The shape of the through groove is circular, the U-shaped groove 1 of the winch can be rotated by the drive motor 3. When the high-speed cold-rolled wire rod rolling line is working normally, the steel bars on the rolling line pass through the U-shaped groove 1 of the winch Over. When the high-speed cold-rolled wire rod rolling line is in an accident state and needs to draw back the steel bars in the laying machine, the drive motor 3 drives the winch to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com