A method for deforming and connecting metal sheets

A metal plate and plate technology, applied in the field of plate connection, can solve the problems of easy to fall off, poor bearing capacity, easy to fall off, etc., and achieve the effect of no need for special equipment, fewer production processes, and low process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

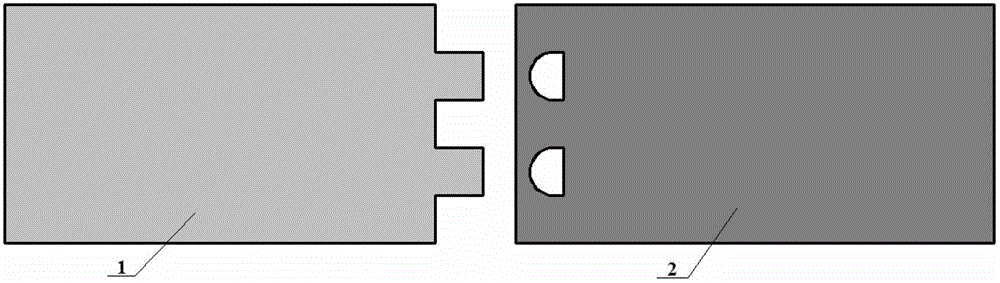

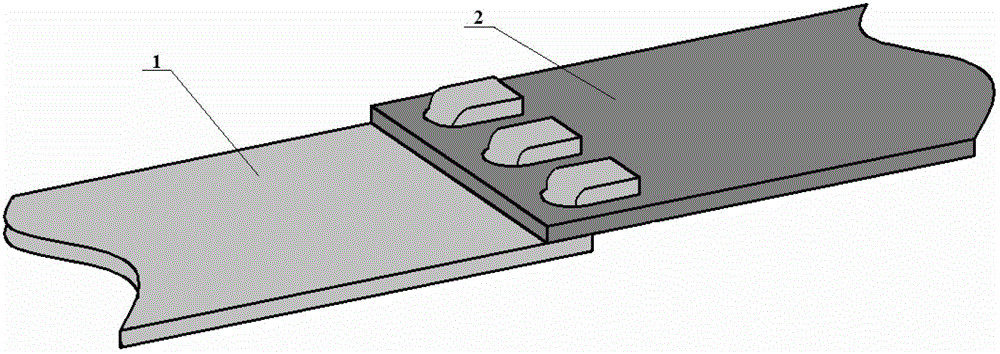

[0034] Specific implementation mode one: as Figure 1 to Figure 4 As shown, the steps of a metal plate cold-press deformation connection forming method are: Step 1, prefabricated plates: respectively determine the end shapes of the first plate 1 and the second plate 2 according to the strength, and the first plate with a lower yield strength 1 Make convex teeth, the second plate with higher yield strength 2 Make holes, and determine the shape of the convex teeth or holes of the plate, the shape of the end of the prefabricated plate is as follows figure 1As shown (the purpose is to achieve the best self-locking effect after the convex tooth is inserted into the hole and loaded and deformed); the structural form of the end of the required connecting plate is pre-designed, and the insertion end of the first plate 1 is made into a rectangle according to the design Protruding teeth (sawtooth shape), and bending and deforming the rectangular protruding teeth upwards, so that the dis...

specific Embodiment approach 2

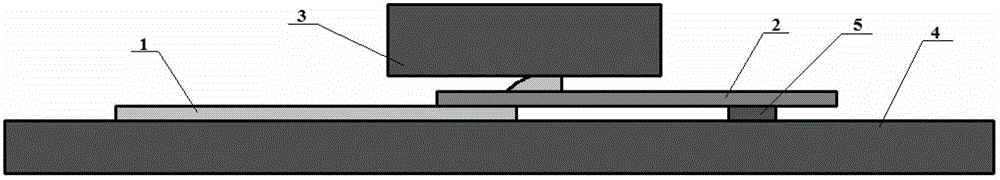

[0035] Specific implementation mode two: as Figure 5 ~ Figure 7 As shown, the steps of a metal plate cold-press deformation connection forming method are: step 1, prefabricated plate: according to the yield strength of the first plate 1 and the second plate 2, prefabricate holes on the second plate 2 with higher yield strength And determine the shape of the hole, the shape of the prefabricated plate joint is as follows Figure 5 As shown (the purpose is to achieve the best connection effect after loading and deformation); step 2, pre-connection: place the pre-connection part of the second plate 2 with the prefabricated hole above the pre-connection part of the first plate 1, The pre-joined two plates such as Figure 6 As shown; step 3, place the prepared sample on the press workbench: place the pre-connected first plate 1 and second plate 2 on the press workbench 4, and position them so that the connecting parts Just at the center position of the press workbench 4, so that ...

specific Embodiment approach 3

[0036] Specific implementation mode three: as Figure 8 ~ Figure 14 As shown, the steps of a metal plate cold-press deformation connection forming method are: Step 1. Prefabricate the plate: pre-design the convex teeth and groove forms at the end of the required connecting plate, and according to the design and the relationship between the yield strength of the two plates, respectively Make sure to process the protruding teeth and grooves on the first plate 1 and the second plate 2. The top view of the ends of the two plates is as follows Figure 8 , the cross-sectional view of the ends of the two plates is shown in Figure 9 (The purpose is to make it load and deform to achieve the best connection effect); step 2, pre-connection: insert the protruding teeth of the first plate 1 with prefabricated protruding teeth into the groove of the second plate 2 with prefabricated grooves , the top view after pre-connection is as follows Figure 10 , the cross-sectional view after pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com