Dual ring rolling production process of thin-sheet wind driven generator

A production process and sheet technology, which is applied in the field of flange forgings, can solve the problems of low production pass rate, poor control of specifications and sizes, warping and deformation of the upper and lower surfaces of sheet wind power flange forgings, etc., and achieve production qualification High efficiency, easy control of specifications and sizes, and smooth upper and lower surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

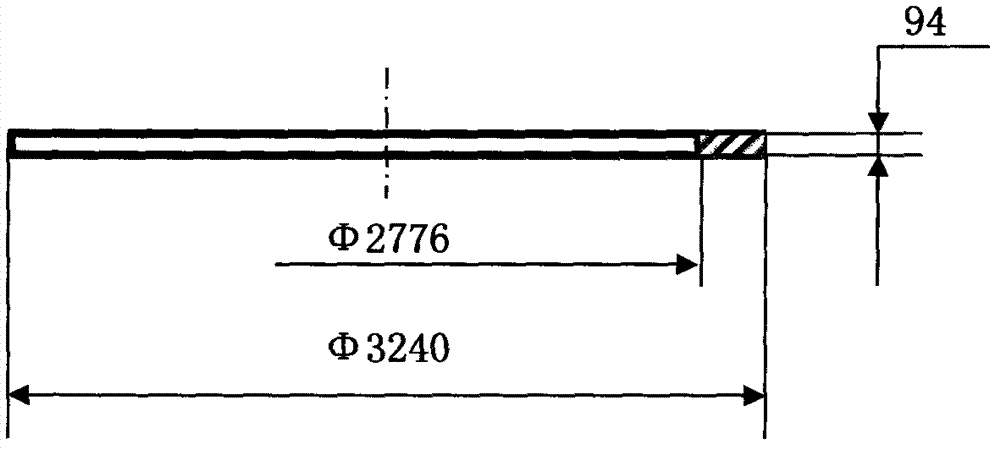

[0025] exist figure 1 In the first embodiment shown, a process for producing a double-rolled ring for a thin-film wind power flange is characterized in that it includes the following steps: 1. a double-blank preparation section, 2. a primary heating section, 3. a double-blank pre-forming section, and 4. two Secondary heating section, ⑤Double ring forming section, ⑥Forging heat treatment section;

[0026] Its specific content is as follows:

[0027] ①Double blank preparation section:

[0028] Select the sawing machine to cut the blank, the size of the blank is Φ600×972 (mm), the quality of a single blank is the quality of 2 pieces of thin wind power flange blanks, and the two ends of the blank are cut with a machine tool to keep the two ends of the blank parallel;

[0029] ② Primary heating section:

[0030] Control the temperature and heating rate of the billet into the furnace, so that the billet is heated up in the forging furnace to reach the initial forging temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com