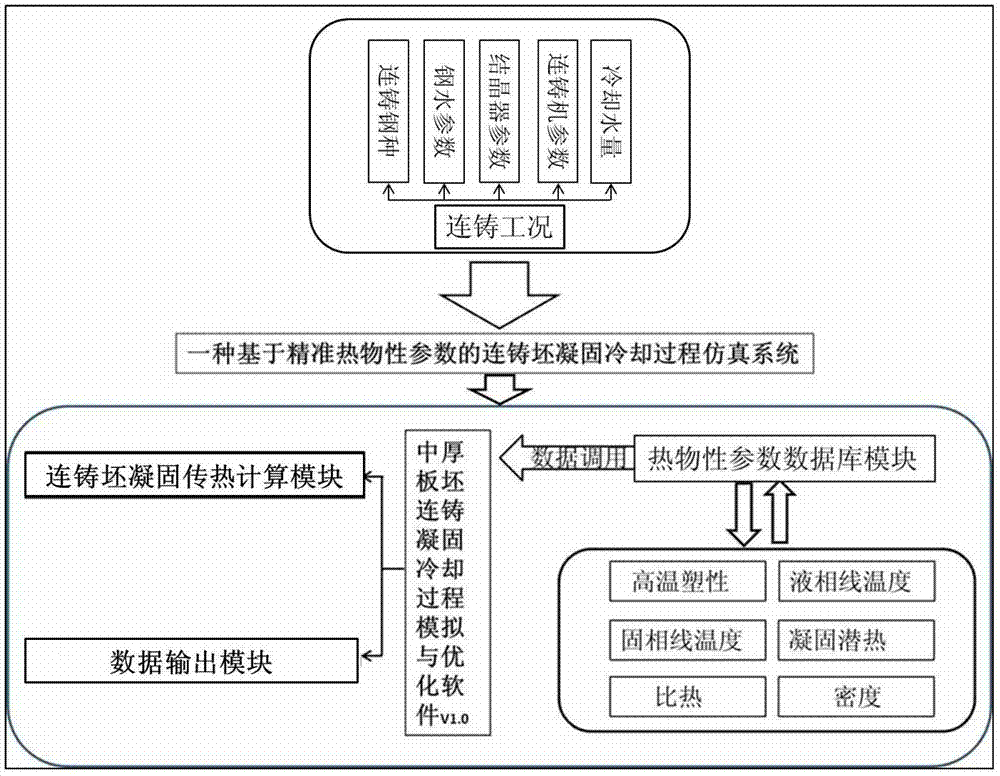

Continuous casting slab solidification cooling process analogy method based on precise thermophysical parameters

A technology of thermophysical parameters and cooling process, which is applied in the field of continuous casting slab quality control, can solve the problems of not establishing a thermophysical parameter database, calculation formulas that cannot meet production needs, and singleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] (1) In order to grasp the solidification status of the slab during the continuous casting production process of this steel type, run the simulation and optimization software V1.0 for the solidification and cooling process of the medium-thick slab continuous casting;

[0029] (2) Call the thermophysical parameter data of X70 steel in the thermophysical parameter database module, select the thermophysical parameter of this steel type and import it into the continuous casting slab solidification calculation module; at the same time, select the high temperature plasticity data of X70 steel as the basis for optimizing the amount of cooling water. If the high-temperature plasticity parameters of a certain steel grade have not been entered in the database, the high-temperature plasticity regression equation obtained in (2) of the content of the present invention is used for calculation by inputting the chemical composition of the steel grade;

[0030] (3) Set the continuous cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com