Angular-type pattern variation simulation decorative film

A decorative film and pattern technology, applied in the field of angular pattern change simulation decorative film, can solve the problems of no variability, singleness, and no three-dimensional effect of the pattern, and achieve the effect of realistic three-dimensional effect, increased durability and gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

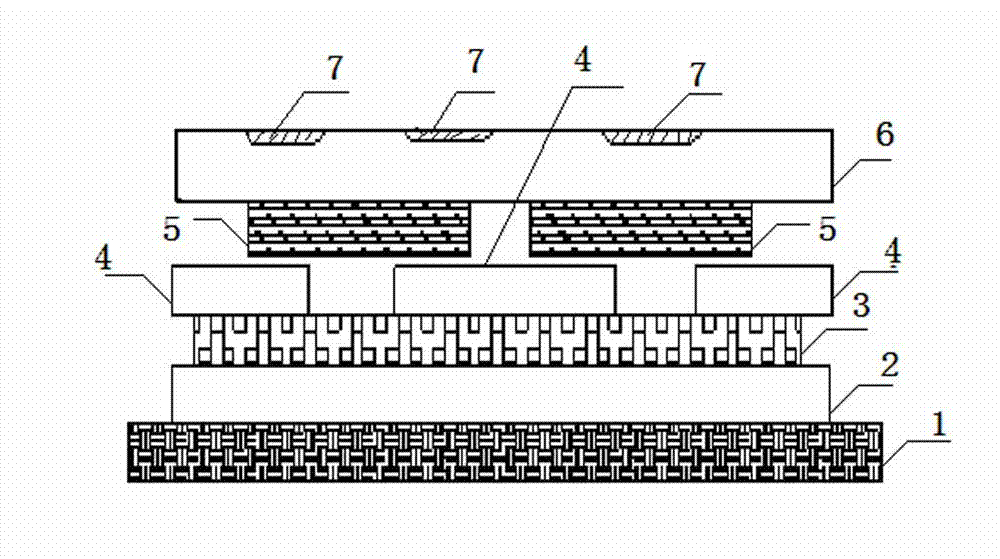

[0014] As shown in the figure, an angled pattern-changing decorative film according to the present invention includes a substrate 1, a spot color layer 2, a pattern color layer 3, a glossy coating 4, a matte coating 5, and a glossy coating 6. The color layer 2 is printed on the upper surface of the substrate 1, the pattern color layer 3 is printed on the upper surface of the spot color layer 2, the glossy coating 4 is printed on the interval area of the pattern color layer, and the matte coating 5 is printed on the glossy coating On the upper surface of the layer 4, the glossy coating 6 is fully printed on the upper surface of the matte coating 5.

[0015] After the printing is completed, due to the misalignment of the matte coating 5 and the glossy coating 4, the angle of the entire coating changes. Set the wood thorn indentation, through refraction, so that the pattern has rich changes, and the outermost layer is printed with a glossy coating 7 again, through the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com