Paenibacillus mucilaginosus and method for producing compound microorganism bacterium agent by utilizing same

A compound microbial inoculant, Bacillus technology, applied in microorganism-based methods, biochemical equipment and methods, chemicals for biological control, etc., can solve the non-degradability of chemical pesticides, pollution enrichment, beneficial biological Threats and other issues, to achieve the effect of reducing the frequency of fertilizer use and the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

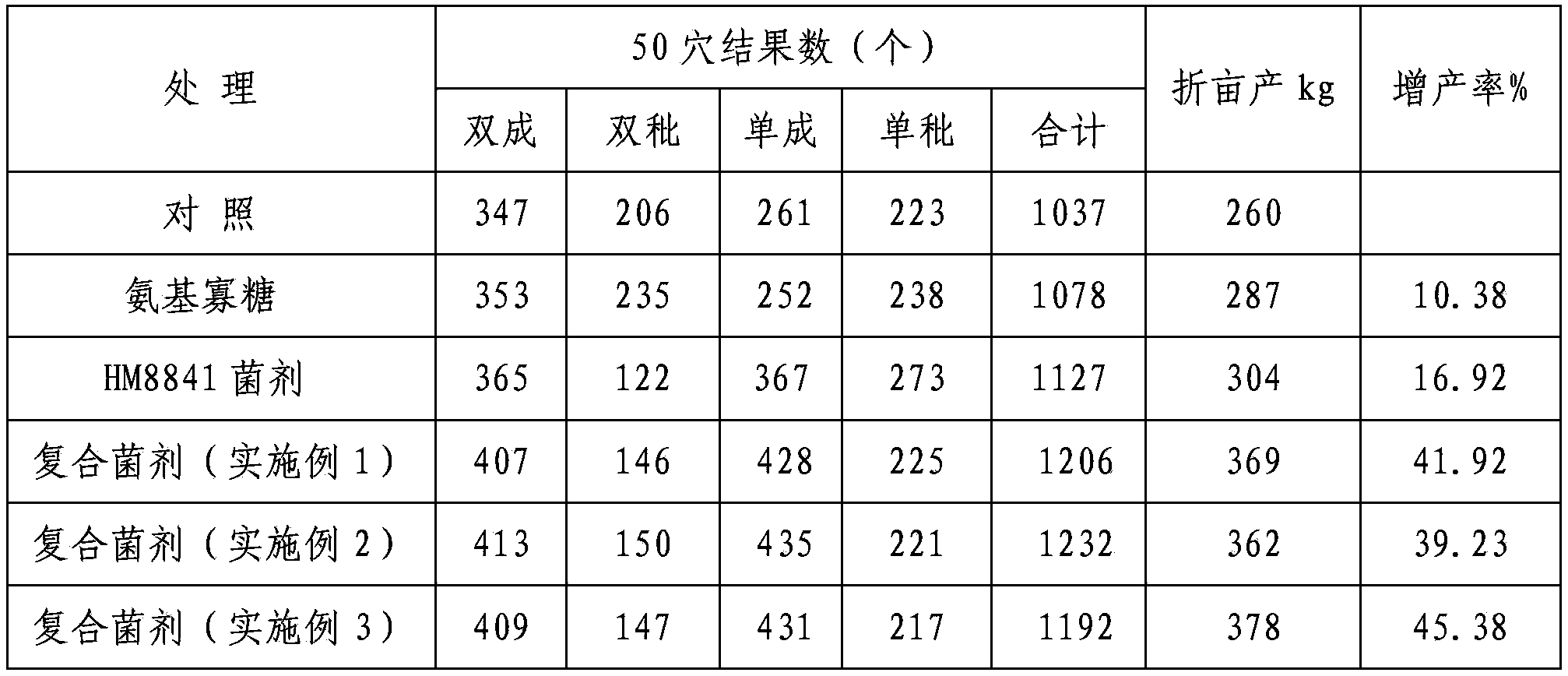

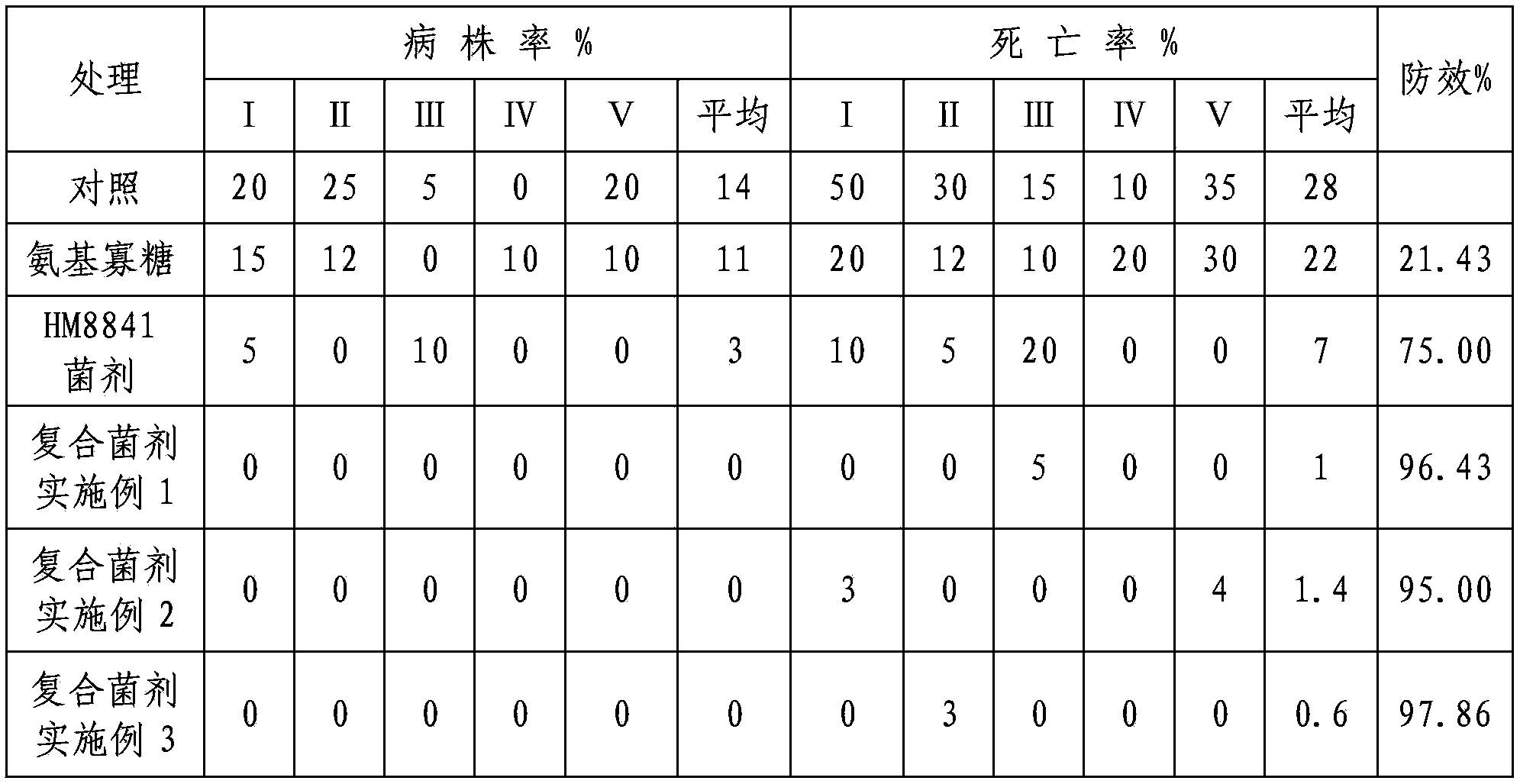

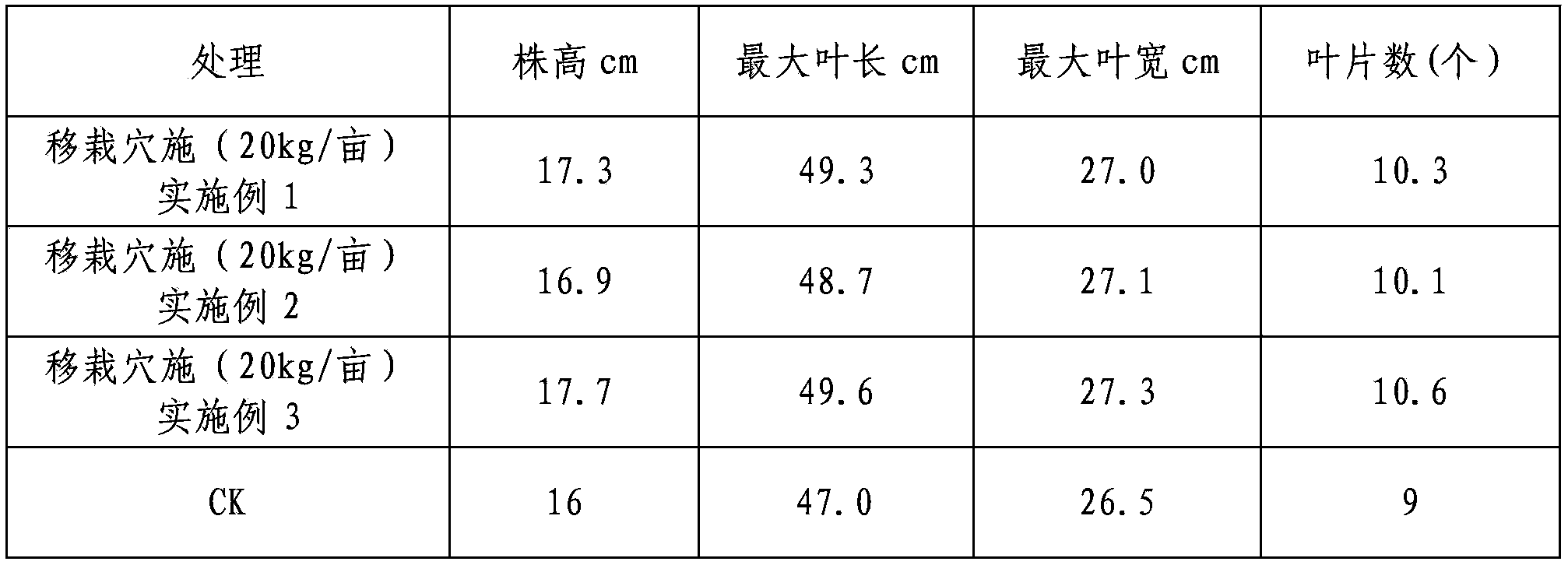

Examples

Embodiment 1

[0042] A jelly-like Paenibacillus mucilaginosus, the preservation number of which is CGMCC No.7240.

[0043] The method for producing composite microbial bacterial agent by using Paenibacillus jelly-like comprises the following process steps:

[0044] A. to expand training

[0045] The original strains are enlarged and cultivated to make production strains;

[0046] Paenibacillus mucilaginosus is selected as the original strain, and its preservation number is CGMCC No.7240;

[0047] B. Preparation of fermentation broth

[0048] B1, fermentation

[0049] According to the volume ratio of the production strain: fermentation medium = 10%, the production strain is inoculated into the sterilized fermentation medium for fermentation. The fermentation conditions are: temperature 25 ° C, pressure 0.03 MPa, ventilation control conditions are : 200M after fermentation starts 3 / hr, 320M after 4 hours of fermentation 3 / hr, 420M after 8 hours of fermentation 3 / hr, 520M after 12 ho...

Embodiment 2

[0068] The method for producing composite microbial bacterial agent by using Paenibacillus jelly-like comprises the following process steps:

[0069] A. to expand training

[0070] The original strains are expanded and cultivated to make production strains;

[0071] Paenibacillus mucilaginosus is selected as the original strain, and its preservation number is CGMCC No.7240;

[0072] B. Preparation of fermentation broth

[0073] B1, fermentation

[0074] According to the volume ratio of the production strain: fermentation medium = 15%, the production strain is inoculated into the sterilized fermentation medium for fermentation. The fermentation conditions are: temperature 32°C, pressure 0.7MPa, ventilation control conditions are : 250M after fermentation starts 3 / hr, 360M after 4 hours of fermentation 3 / hr, 70M after 8 hours of fermentation 3 / hr, 560M after 12 hours of fermentation 3 / hr, 630M after 20 hours of fermentation 3 / hr, start stirring after 8 hours of ferm...

Embodiment 3

[0093] The method for producing composite microbial bacterial agent by using Paenibacillus jelly-like comprises the following process steps:

[0094] A. to expand training

[0095] The original strains are enlarged and cultivated to make production strains;

[0096] Paenibacillus mucilaginosus is selected as the original strain, and its preservation number is CGMCC No.7240;

[0097] B. Preparation of fermentation broth

[0098] B1, fermentation

[0099] According to the volume ratio of the production strain: fermentation medium = 12%, the production strain is inoculated into the sterilized fermentation medium for fermentation. The fermentation conditions are: temperature 30 ° C, pressure 0.2 MPa, ventilation control conditions are : 230M after fermentation starts 3 / hr, 350M after 4 hours of fermentation 3 / hr, 450M after 8 hours of fermentation 3 / hr, 550M after 12 hours of fermentation 3 / hr, 620M after 20 hours of fermentation 3 / hr, start stirring after 6 hours of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com