Improved pulverizer knife holder and production method thereof

A pulverizer and knife holder technology, applied in grain processing, etc., can solve problems such as poor mechanical properties, and achieve the effects of prolonged service life, high strength and hardness, and excellent toughness

Inactive Publication Date: 2013-07-10

宁波大榭信易电热有限公司

View PDF11 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] Aiming at the problem of poor mechanical properties of the current grinder blade holder, the present invention provides a method for producing a high-strength, high-toughness grinder blade holder

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0054] The preparation method of pulverizer knife holder described in the present embodiment is as follows:

[0055] step 1

[0056] According to the chemistry of C3.65-3.80%, Si1.8-2.0%, S0.02%, P0.04%, Mn0.4%, Cr0.1%, Cu0.05%, Al0.03%, and the rest is iron Component ratio, provide scrap steel 250kg, return material 250kg, recarburizer 10kg, ferrosilicon (Fe-Si) 3kg.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

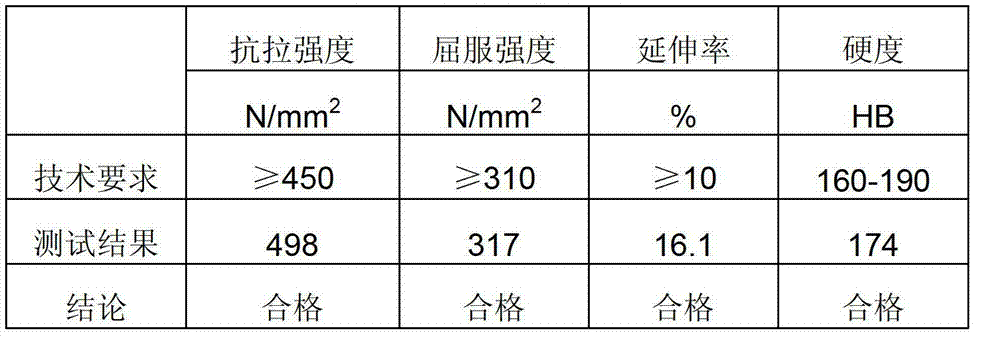

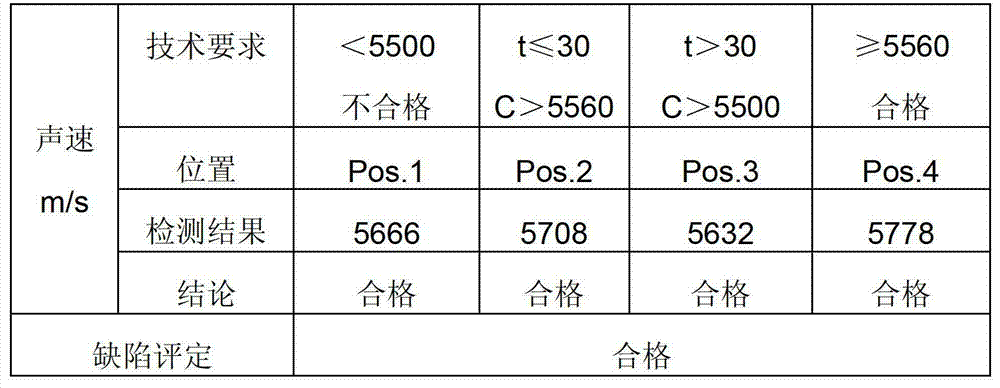

The invention provides an improved pulverizer knife holder and a production method thereof. The pulverizer knife holder is an iron casting and comprises the following chemical components by weight percent: 3.2-4.0 % of C, 2.1-3.1 % of Si, less than or equal to 0.4 % of Mn, less than or equal to 0.05 % of P, less than or equal to 0.02 % of S, 0.035-0.05 % of Mg, 0. 01-0.05 % of Cu, 0.001-0.02 % of Ni, and trace rare earth element (or including Ba element as well). During a casting process of the pulverizer knife holder, trace rare earth element or trace Ba element is added, thereby obtaining relatively high intensity and hardness, and good toughness, especially with a percentage elongation being up to 16 %.

Description

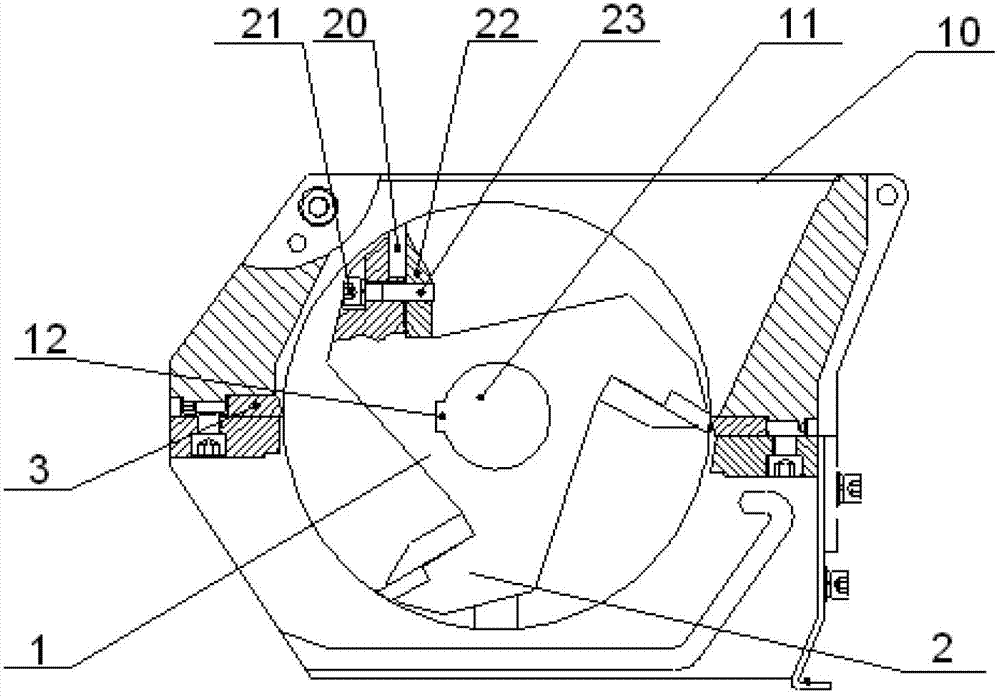

technical field [0001] The invention relates to a crushing equipment component, in particular to a crushing tool holder with excellent mechanical properties and a production method thereof. Background technique [0002] The use of knives to crush objects has been applied in more and more fields, such as the crushing of objects such as plastics, garbage, paper, grass, meat, vegetables, and grains. [0003] For example, patent CN102091667A discloses a combination cutter for crushing plastics, including a large blade and a small blade segment spliced by small blades. The large blade and the small blade segments rotate synchronously, and material cutting is realized through the dynamic and static cooperation between the knife groove of the press knife and the blade. During the high-speed rotation of the blade, the blade is crushed after contact with the material, and the blade is easily damaged. In this patented technology, the blade is large in size, and all blades need to be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C37/10C22C33/08B02C18/18

Inventor 赵奕苍

Owner 宁波大榭信易电热有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com