Drainage system of solid waste disposal site

A solid waste and drainage system technology, applied in protection devices, buildings, infrastructure projects, etc., can solve the problems of increasing the risk of flooding in the disposal unit 12, increasing the risk of nuclide release and migration, and large investment, reducing The effect of maintaining workload and personnel exposure dose, improving long-term natural safety, and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

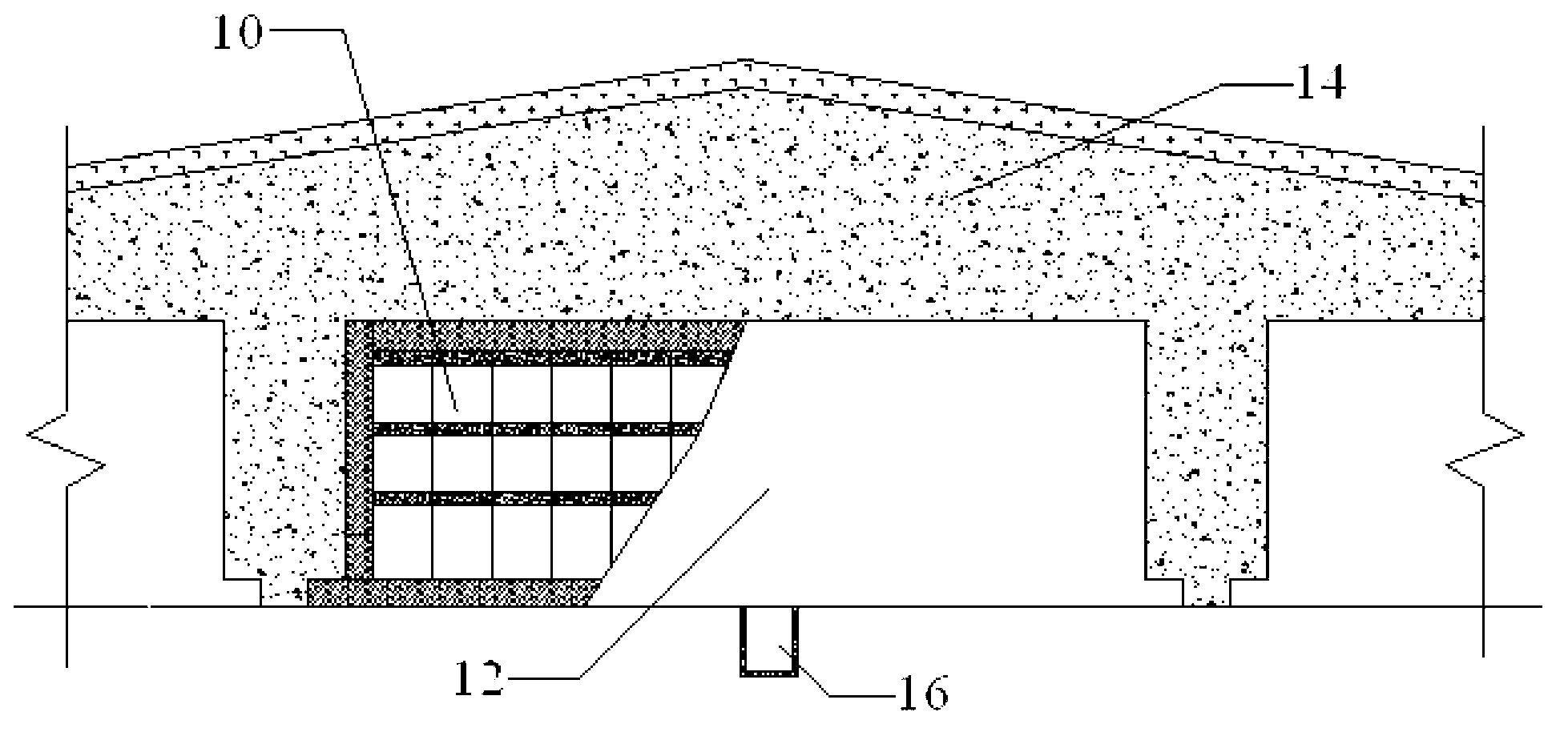

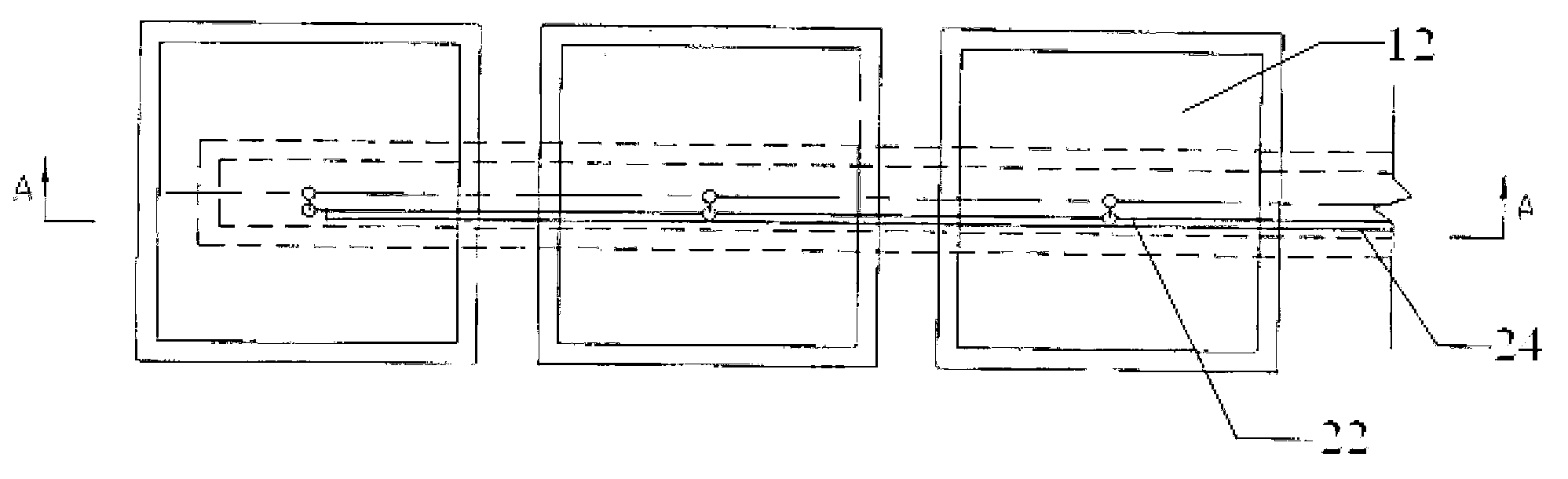

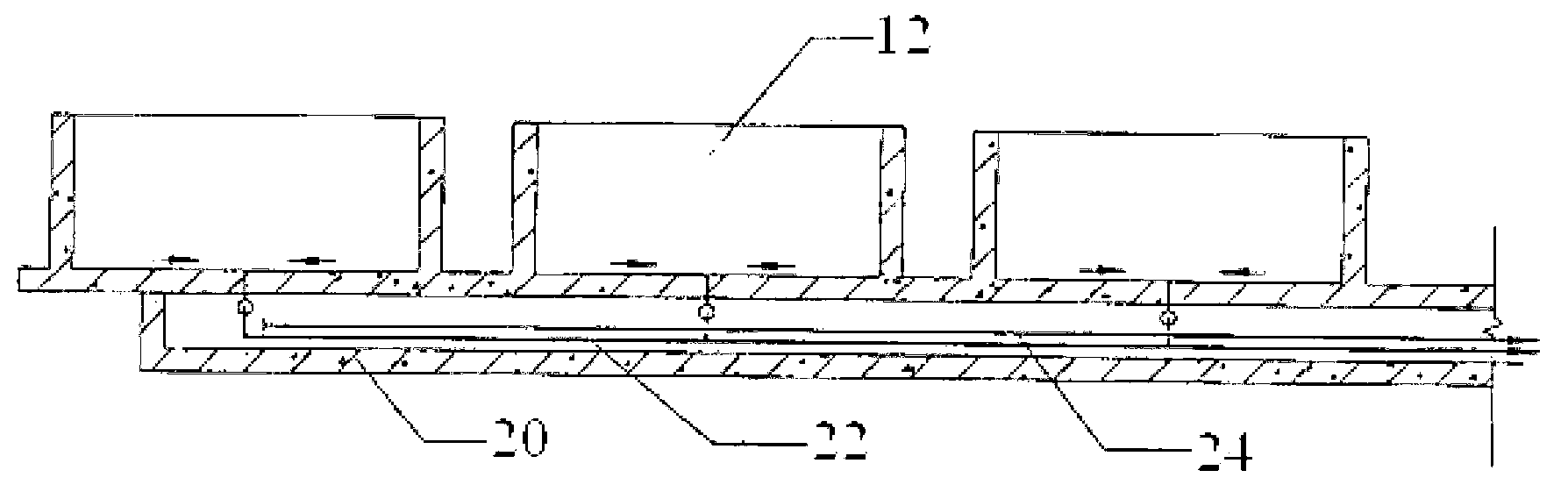

[0032] The first embodiment of the drainage system of the solid waste disposal site of the present invention is a pipe gallery scheme, which includes a disposal unit, a dialysis water collection system, and a dialysis water collection and treatment plant.

[0033] see Figure 4 , the bottom plate 32 of the handling unit includes two opposite first sides 320 , one second side 322 and one third side 324 opposite to the second side 322 . The bottom plate 32 is provided with a downward slope of 1% from the two first sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com