Device and method of engine, based on cam and with variable oil supply correct time and duration

An engine and duration technology, which is applied to engine components, machines/engines, fuel injection devices, etc., can solve problems such as increased engine cost, decreased reliability, and gear damage, and achieves the goals of reducing emissions, improving power and economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in combination with specific embodiments.

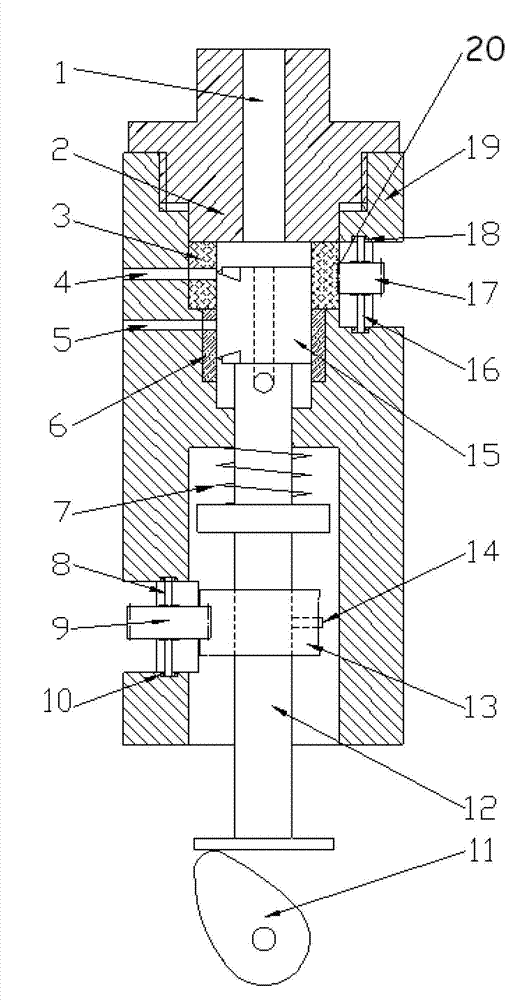

[0017] Such as figure 1 Shown is a cam-based engine variable oil supply timing and duration device of the present invention, including a pump body 19, a pump cover 2, a plunger 15, a plunger sleeve, a plunger spring 7, a push rod 12 and an engine cam 11.

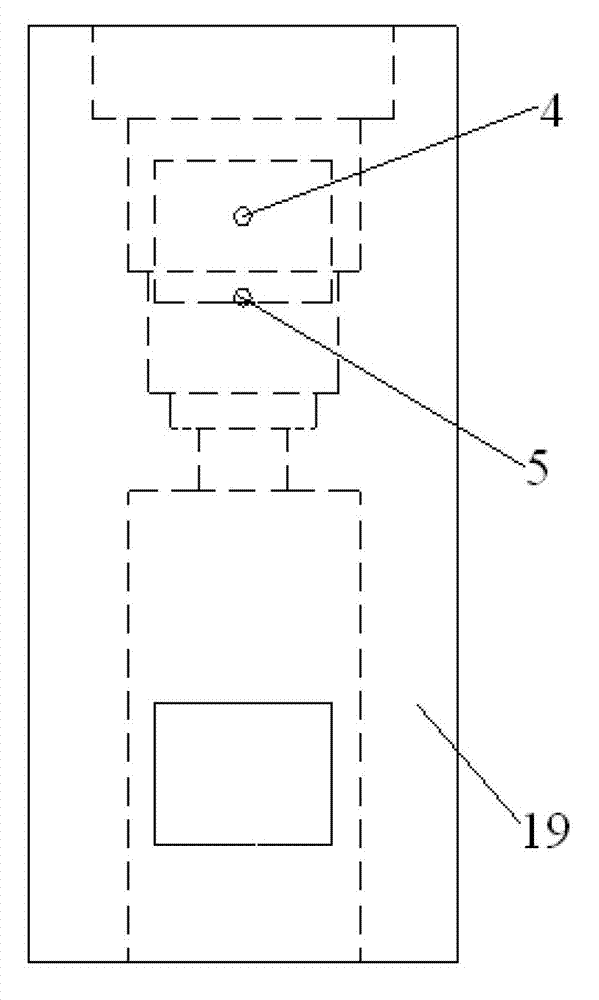

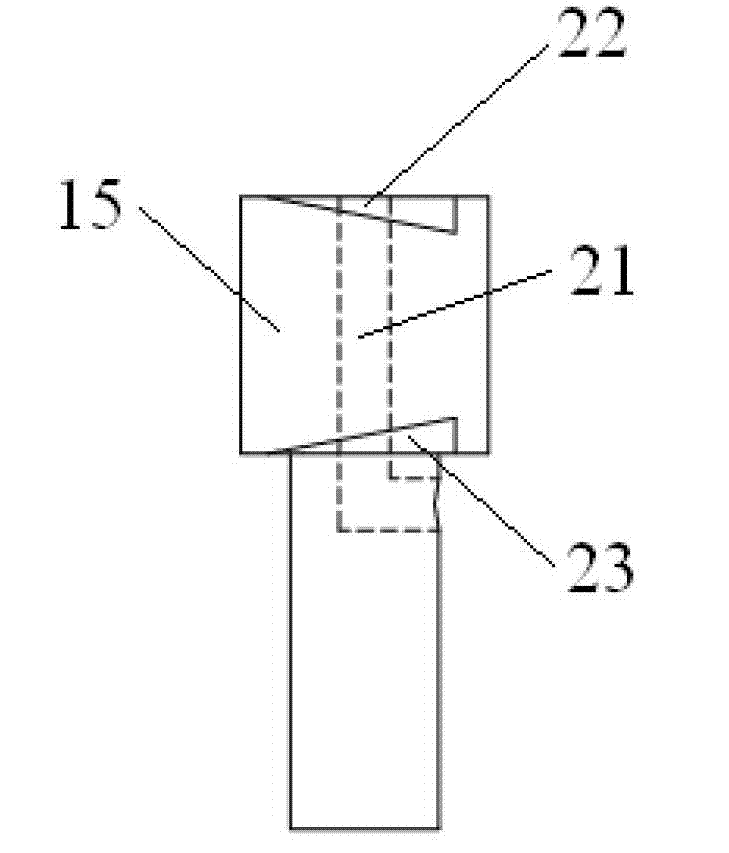

[0018] The plunger sleeve is slidingly fitted with the plunger 15, the plunger 15 is connected with the push rod 12, and the upper part of the pump body 19 is provided with a first oil inlet and outlet passage 4 and a second oil inlet and outlet passage 5 ( Such as figure 2 shown); the upper part of the pump body 19 is provided with a first control gear 17, and the lower part of the pump body 19 is provided with a second control gear 9; the plunger sleeve is composed of a plunger sleeve upper body 3 and a plunger sleeve The lower body 6 is formed. The upper body 3 of the plunger sleeve and the lower body 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com