Infrared thermal imaging temperature measuring method by correcting surface emissivity through image segmentation

A technology of infrared thermal imaging and surface emissivity, applied in the field of infrared temperature measurement, can solve the problems of infrared temperature measurement result error, not allowing target objects, temperature measurement result error, etc., to overcome errors, equipment requirements are simple and easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

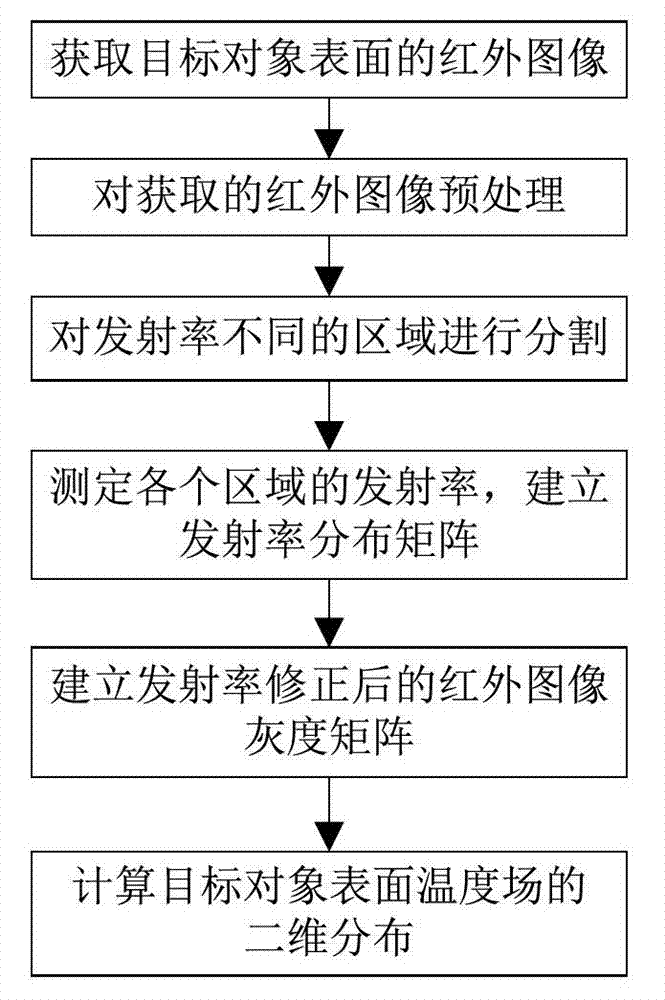

Method used

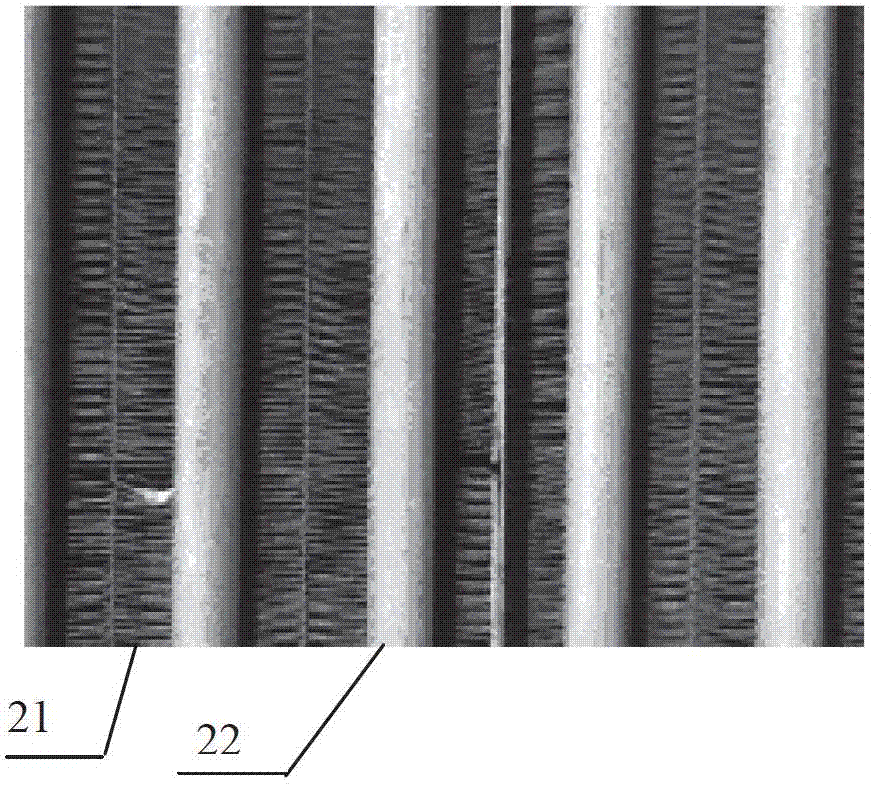

Image

Examples

Embodiment Construction

[0026] Taking the 600MW air-cooling unit of Ningxia Lingwu Power Plant as an example, a specific embodiment of an infrared thermal imaging temperature measurement method for correcting surface emissivity through image segmentation and correcting surface emissivity disclosed by the present invention will be further explained in conjunction with the accompanying drawings:

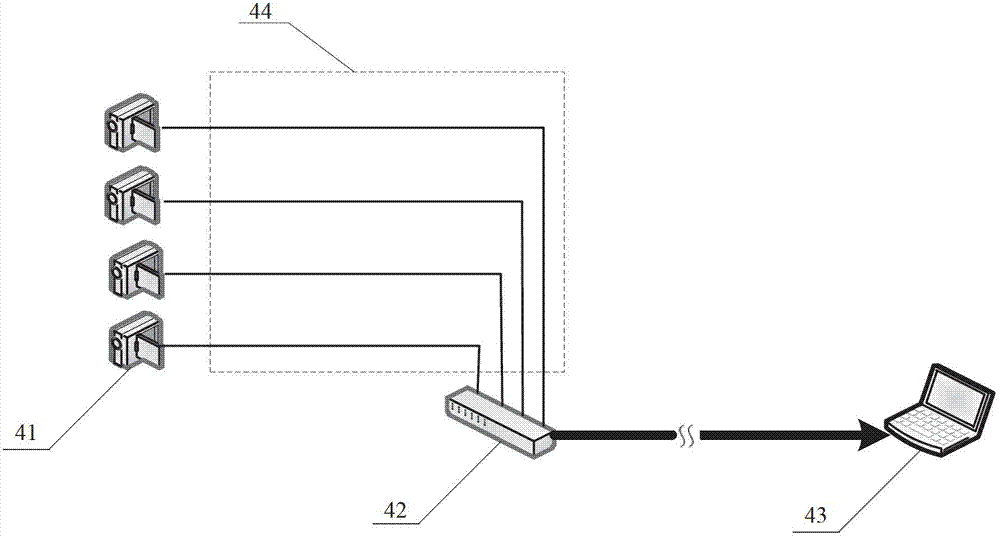

[0027] Construct the movable support 31 with the help of the existing cleaning support of the air-cooling unit of the power plant, as attached image 3 shown. The top and bottom of the support 31 are provided with pulleys, and guide rails are laid on the top and bottom of the heat dissipation surface of the air-cooling unit to push the support to move parallel to the heat dissipation surface of the air-cooling unit. An infrared camera fixing device is installed on the bracket, so that the infrared camera can be installed and removed flexibly. In the fixed infrared camera 41 (as attached Figure 4 As shown),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com