Structural dynamic defective optical fiber microscopic monitoring device

A monitoring device and optical microscope technology, which is used in measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of defect fiber microscopic monitoring devices and measuring devices that cannot monitor the surface condition, and achieve high precision and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

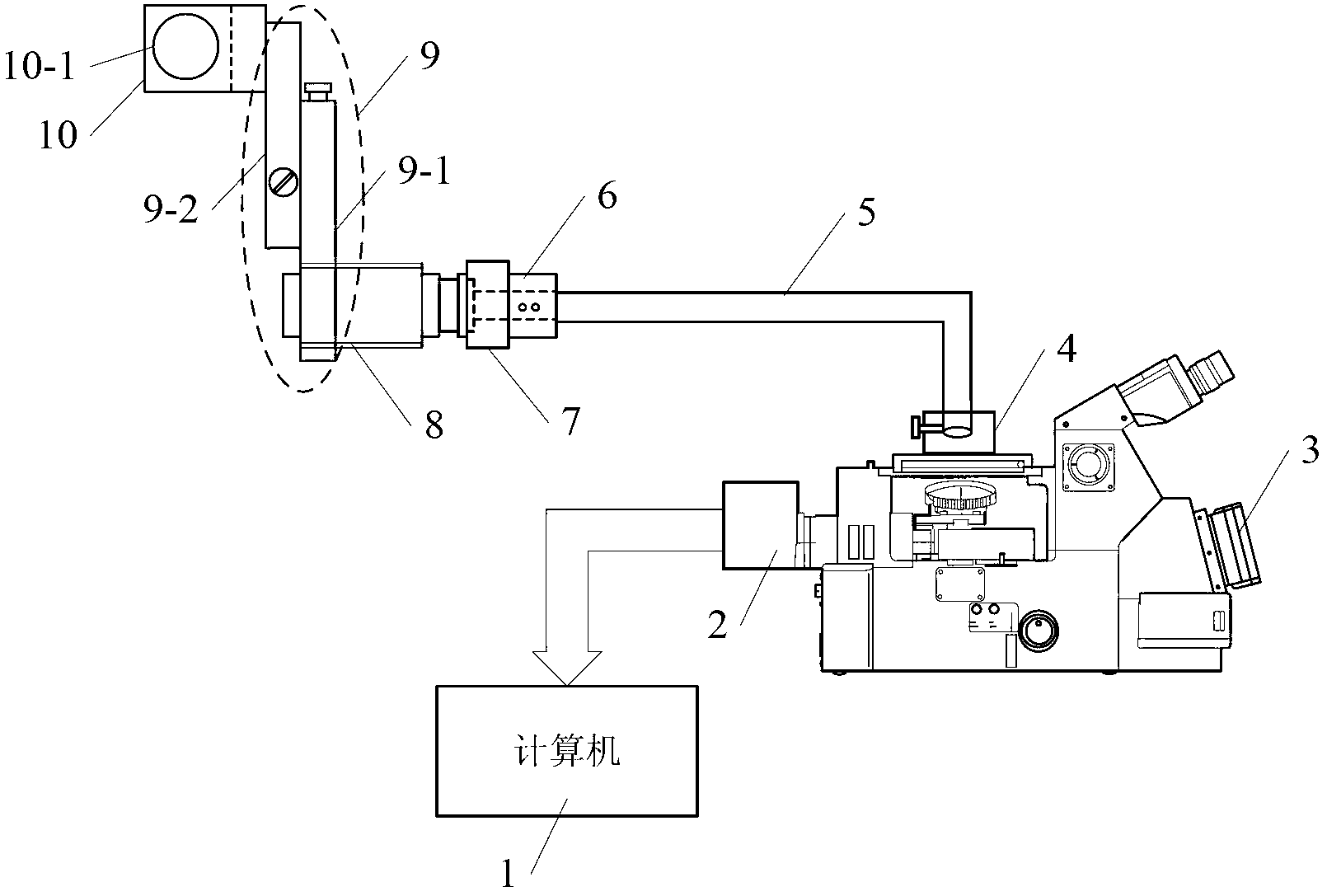

[0031] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment mode, a fiber optic microscopic monitoring device for structural dynamic defects described in this embodiment mode, which includes: a computer 1, a CCD camera 2, an optical microscope 3, a fixed block 4, an optical fiber image transmission bundle 5, an adapter 6, a micro Microscope 7, threaded interface 8, two-dimensional fine-tuning system 9 and fixture 10;

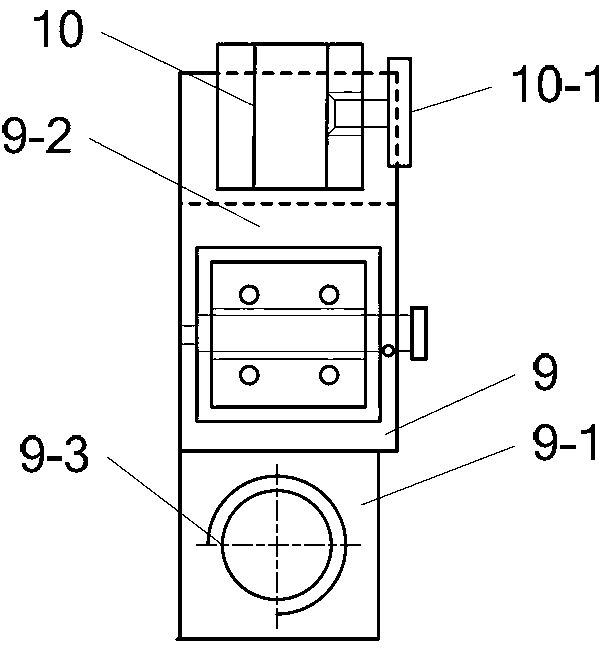

[0032] The two-dimensional fine-tuning system 9 includes a longitudinal adjustment mechanism 9-1 and a horizontal adjustment mechanism 9-2; and one end of the longitudinal adjustment mechanism 9-1 is provided with a connecting threaded through hole 9-3;

[0033] The clamp 10 includes a U-shaped groove and a locking knob 10-1; the locking knob 10-1 is arranged on a side wall of the U-shaped groove;

[0034] The bottom of the U-shaped groove of the clamp 10 is fixedly connected to the lateral adjustment mechan...

specific Embodiment approach 2

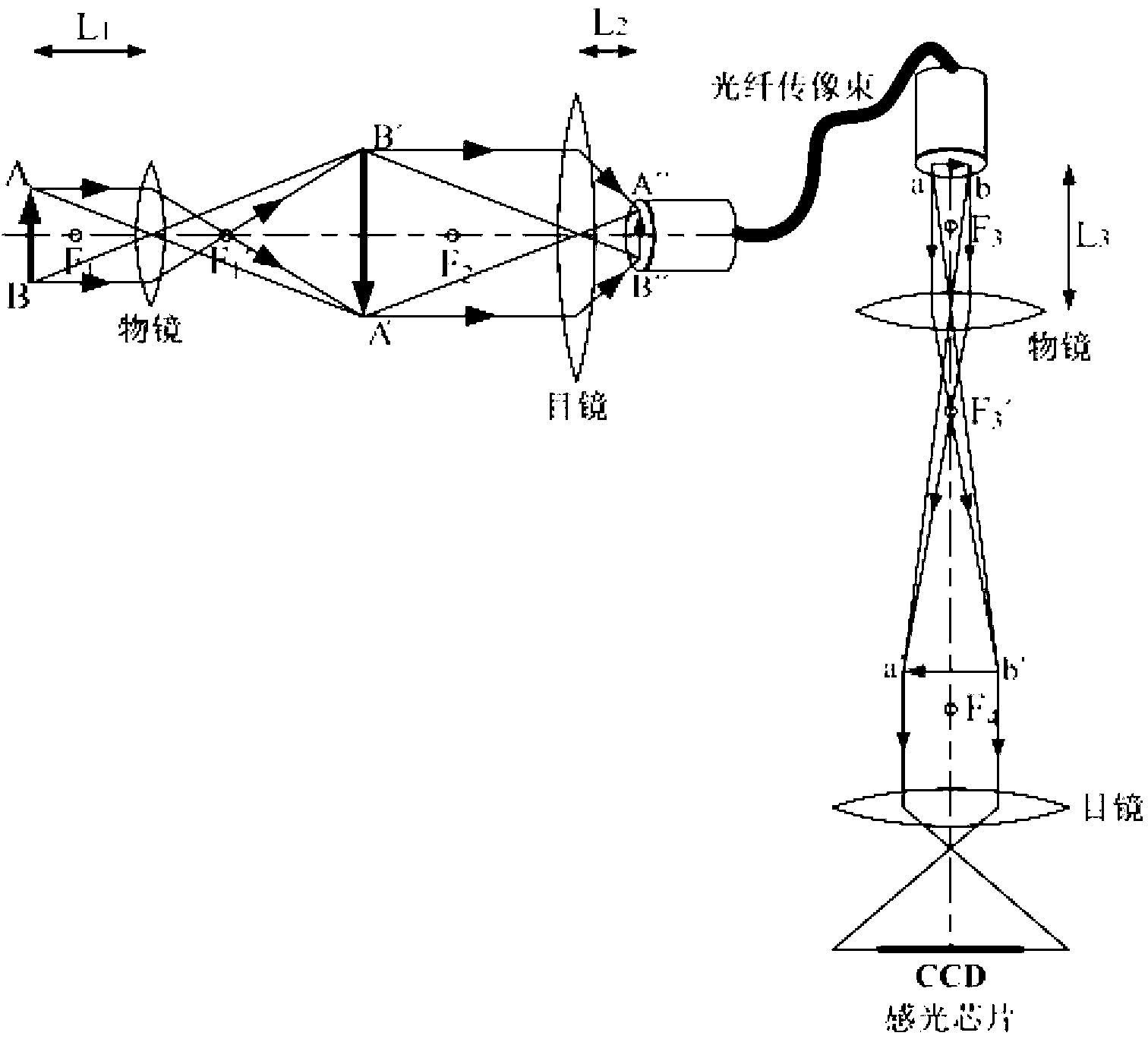

[0039] Specific implementation mode two: the following combination figure 2 This embodiment will be described. This embodiment will further describe the first embodiment. The vertical distance between the objective lens of the micromicroscope 7 and the sample to be measured in this embodiment is 20 mm to 22 mm.

specific Embodiment approach 3

[0040] Specific implementation mode three: the following combination figure 2 This embodiment will be described. The first embodiment will be further described in this embodiment. The distance between the eyepiece of the micromicroscope 7 and one end of the optical fiber image transmission bundle 5 in this embodiment is 5 mm to 7 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com